by Gary Mintchell | Aug 6, 2015 | Automation, Data Management, Internet of Things, Networking, News, Operations Management, Technology

Industrial Internet of Things dominated keynotes and discussions during the annual National Instruments developer gathering known as NI Week.

There was less talk of cyber-physical systems and more discussion of benefits to managers and consumers, as well as the usual engineering target audience.

As usual, many customers and partners appeared on stage showing off some incredible feats of engineering built upon the foundation of NI products.

Dr. James Truchard, president, CEO, and co-founder, established the conference theme in his keynote, “ We have always been concerned with data. LabView is built for data flow as well as control. We have created a platform allowing standardized ways of interacting with the world that we call graphical systems design.”

Eric Starkloff, executive vice president sales and marketing, stated, “We are instrumenting the world. It’s like the Cambrian explosion of data. Diversity of data is evolving at a very rapid rate.”

He continued, “We’ve collected data for years, what has changed—connectivity.”

Jeff Kodosky, NI co-founder and “father of LabView,” devoted much of his presentation to point out the tremendous potential for the industrial Internet of Things—potentially of greater impact than the consumer Internet of Things.

One last thought brought home by Marketing Vice President John Graff involved the leveraging the power of the Industrial Internet of Things for predictive maintenance. “It can save 30% on maintenance and 45% on downtime according to US DOE. This led to a discussion of the test bed with IBM that I wrote about last week.

Product announcement

The most significant of the products announced this week was LabView 2015. The theme of the product release is, “write code faster; write faster code.”

Stated in the press release, the latest version of LabVIEW delivers speed improvements, development shortcuts, and debugging tools.

“Using LabVIEW and the LabVIEW RIO architecture allowed us to reduce the time of developing and testing a new robot control algorithm to just one week, compared to one month with a text-based approach. We are able to prototype with software and hardware faster and adapt to rapidly changing control requirements quicker,” said DongJin Hyun, Senior Research Engineer (Ph.D.), Central Advanced Research and Engineering Institute, Hyundai Motor Group

LabVIEW 2015 further equips engineers with support for advanced hardware such as the quad-core Performance CompactRIO and CompactDAQ Controllers, 8-core PXI Controller, and High Voltage System SMU.

LabVIEW 2015 also reduces the learning curve for employing a software-designed approach to quickly create powerful, flexible, and reliable systems. With three application-specific suites that include a year of unlimited training and certification benefits, developers have unprecedented access to software and training resources to build better systems faster.

Following is a list of features:

• Open code faster—open large libraries up to 8X faster and eliminate prompts to locate missing module subVIs

• Write code faster—execute common programming tasks faster with seven new time-saving right-click plugins and develop your own additional plugins to maximize your productivity

• Debug code faster—examine arrays and strings in auto-scaling probe watch windows and document findings with hyperlink and hashtag support in comments

• Deploy code faster—offload your FPGA compilations to the LabVIEW FPGA Compile Cloud service included with your Standard Service Program membership

LabVIEW 2015 is extended by the LabVIEW Tools Network, which has been enriched by IP both from NI and third-party providers. The new Advanced Plotting Toolkit by Heliosphere Research furnishes developers with powerful programmatic plotting tools to create professional data visualizations. The RTI DDS Toolkit by Real-Time Innovations enables IoT applications with scalable peer-to-peer data communication. Additionally, application-specific libraries for biomedical, GPU analysis, and Multicore Analysis and Sparse Matrix applications are now available free of charge.

by Gary Mintchell | Dec 4, 2014 | Automation, Motion Control

Technosoft, based in Neuchâtel, Switzerland, has released the first member of its iMOT line of motors with integrated motion controller and drive — the iMOT172S XM-CAN intelligent stepless motor.

based in Neuchâtel, Switzerland, has released the first member of its iMOT line of motors with integrated motion controller and drive — the iMOT172S XM-CAN intelligent stepless motor.

The product is based on a cost-effective hybrid step motor on which the motion control specialists at Technosoft have integrated a magnetic encoder, together with a member of their powerful iPOS motion controllers, into a very compact package (42 x 42 x 70 mm).

The design is made, for high reliability, with only one PCB incorporating the encoder and the iPOS controller that utilizes the Technosoft MotionChip technology and provides 7 I/Os. The configuration, tuning and local programming of the iPOS drive can easily be done using Technosoft’s powerful graphical platform, EasyMotion Studio. The position sensor is absolute single-turn, providing 4096 counts per revolution for accurate speed and position control, down to 5 arc minutes.

While an EtherCAT version is under preparation, the current release covers two CAN versions: the standard CANopen, in accordance to the CiA 301, 305 and 402 profiles, and the TMLCAN protocol. TML (Technosoft Motion Language) opens the possibility to use the powerful motion controller, allowing it to operate as an independent intelligent device. As an example, any homing routine can be customized to match the application needs. Standalone single- or multi-axis applications with communication between drives without the need of a CAN master are possible, while various types of CAN masters are as well supported through an extended set of Technosoft Motion Control Libraries.

This intelligent stepless motor reaches a peak torque of 500 mNm at 1000 rpm without a gearbox, achieved from a motor with a square flange of 42 mm. The maximum length of the integrated unit is a mere 70 mm. The high efficiency of the solution is obtained due to Technosoft’s implementation of current and torque vector regulation under a field oriented control method (FOC) that practically transforms the motor into a stepless servo motor, dramatically reducing the current consumption and heat dissipation typical to hybrid steppers.

The standard NEMA17 flange ensures multiple sources of gearheads that are available for fitting to the motor, depending on the requirements of the application.

An intelligent motor can be used in many applications, but it has been developed for medical analysis and dosing machines, pick and place and welding robots, instrumentation and optical equipment, unmanned military vehicles, packaging, bottling and labeling machines.

Intelligent Motion Control Drive

It has also rele ased the iPOS3604 HX-CAN—a closed frame intelligent drive offering a very compact solution for sinusoidal or trapezoidal position, speed and torque control of rotary or linear DC Brushless and open-loop or closed-loop control of 2-phase and 3-phase step motors requiring power up to 144 watts. The supply voltage range is 12 to 36 VDC with a continuous current of 4 A, (10 A peak) and a PWM frequency of 20 KHz.

ased the iPOS3604 HX-CAN—a closed frame intelligent drive offering a very compact solution for sinusoidal or trapezoidal position, speed and torque control of rotary or linear DC Brushless and open-loop or closed-loop control of 2-phase and 3-phase step motors requiring power up to 144 watts. The supply voltage range is 12 to 36 VDC with a continuous current of 4 A, (10 A peak) and a PWM frequency of 20 KHz.

This high performance servo drive offers high level single or multiple-axis control functions such as master, slave or standalone operations in a small package of only 80 x 55 x 16 mm. Although extremely compact, iPOS3604 HX embeds motion controller, drive and PLC functionality in one unit.

iPOS3604 HX can operate as a CiA402 CANopen drive, or can be programmed to execute complex motion programs directly at drive level, using their built-in motion controller and the high level Technosoft motion language (TML).Thanks to the TML instruction set, the iPOS3604 HX is an intelligent drive, programmable at user’s level and offering position and speed profiles, PVT & PT interpolated, electronic gearing and cam, external reference: analogue or sent via a communication bus.

The configuration, tuning and programming of the iPOS3604 HX-CAN drive is easy with Technosoft’s powerful graphical platform, EasyMotion Studio. System configuration and parameterization are performed by selecting and testing the system structure, motor and sensor types and control mode.

Flexibility and easy implementation make the iPOS3604 BX-CAN drives an ideal solution to fulfilling today’s motion axis control needs, using modern distributed intelligence architecture.

by Gary Mintchell | Dec 2, 2014 | Automation, Motion Control, News, Operations Management, Process Control, Software, Technology

Every Rockwell Automation software executive and product manager who talked with me at Automation Fair almost gushed over the latest and major release of Rockwell Software Studio 5000 Logix Designer v24 (with a name that long, it’d better be good).

Every Rockwell Automation software executive and product manager who talked with me at Automation Fair almost gushed over the latest and major release of Rockwell Software Studio 5000 Logix Designer v24 (with a name that long, it’d better be good).

According to the press release, “Engineers have new design capabilities that can dramatically increase automation productivity, improve start-up time and reduce costs throughout a project’s life cycle. The new additions include an application-centric view of code, enhanced work flows for more efficient re-use of content, and new collaborative tools that make it easier for multiple people to work together.”

“Many machine builders and manufacturers struggle to support production changes due to unstructured code that is not easily understood and organized,” said Mike Brimmer, product manager, Rockwell Automation. “The Studio 5000 Logix Designer v24 software improves the design experience by more intuitively aligning the control system with the manufacturing operation, thus leading to enhanced automation productivity.”

As part of a contemporary automation engineering design environment, the Studio 5000 Logix Designer v24 software is used to configure Allen-Bradley Logix5000 controllers from Rockwell Automation for discrete, process, batch, motion, safety and drive control.

The Studio 5000 Logix Designer v24 software features a new logical organizer that arranges program code based on the users’ applications – rather than how the programmable controller executes. Logical organization of program code can help users identify and troubleshoot code faster for improved downtime recovery.

New library management workflows, meanwhile, ease the ability to store and re-use intellectual property. Users can simply drag and drop modules of code from the Studio 5000 Logix Designer v24 library into a new project. The new workflows enable design engineers to re-use sections of code, which reduces design time and eases the ability to make future operational changes.

Automation system design and maintenance teams are increasingly global and specialized by function. This highlights an increasing need for more powerful collaborations tools. The Studio 5000 Logix Designer v24 software is addressing this need by building on its already strong baseline of multiuser capabilities, which allows many users to work separately and then bring their work back together.

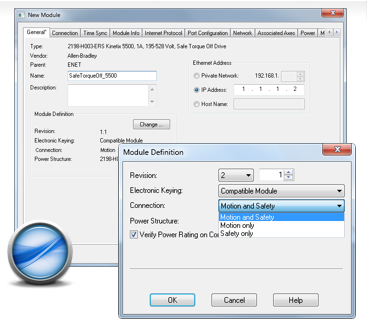

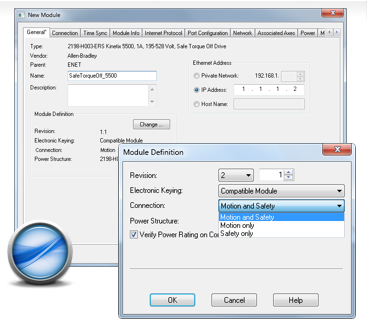

In addition, the Studio 5000 Logix Designer v24 software supports the Allen-Bradley Kinetix 5500 servo drive with integrated safety to help machine builders reduce development and installation time. It also provides support that allows the Allen-Bradley PowerFlex 527 AC drive to be the first variable frequency drive to exclusively use the motion instruction sets within the Studio 5000 Logix Designer v24 software for machine control and motor synchronization.

Additionally, the Allen-Bradley Dynamix 1444 integrated condition-monitoring system allows manufacturers to leverage the Rockwell Automation Integrated Architecture system, rather than an isolated condition-monitoring device. It helps assess current equipment health, predict potential issues, and help avoid damage to critical machinery.

by Gary Mintchell | Nov 6, 2014 | Automation, Data Management, Manufacturing IT, Operations Management, Software, Technology

There is a place for closed, proprietary manufacturing software. But standards and open source have proven to be a perfect way to solve additional integration and development problems for integrators and end users. And maybe add some excitement, enthusiasm and innovation, as well.

This post began from a ping on Twitter. Then an email conversation. Then some exploration.

I have followed Andy Robinson (aka @Archestranaut) for several years. As Eliot Landrum explained to me, “He started a project a little bit ago and we are picking up with a renewed interest. Our website can be found here, plus we also have the Twitter account and, most importantly, a GitHub repository.”

The main objective is to build an open, public community among (Schneider Electric/Wonderware) ArchestrA developers. Adds Landrum, “I personally have desired a public, technical conversation among our industry but haven’t found it. So, I decided to make it happen. Other programming communities have gained so much from public, open discussion and code sharing and I want some of that for us! I really think that we can build on each other’s successes and create a friendly community of knowledgeable developers.”

The Website will include tricks, techniques, and tutorials for improved manufacturing software implementation. In the GitHub repository, programmers will share real code! These will be anywhere from simple scripts to full-blown tools. “Anyone is welcome to submit code for inclusion, and Andy and I will be reviewing and monitoring the code,” concludes Landrum.

From the Website

So, what’s this all about anyway? Personally, I think it’s about helping to open up an industry that has been tight-fisted and scared to share anything of value. The automation / system integration industry has traditionally been very secretive about the tools we use and develop in-house. As we’ve seen from the Open Source movement’s success over the past 20 years, this “scared to share” route is a lousy path to take. The advantages of knowledge and code sharing across an industry are well understood and easily observed in industries such as web and mobile app development. Those industries have seen tremendous technical growth and advancement because developers across the industry are sharing knowledge and skills. They have been able to build on each other’s successes to create better tools, resources, and platforms.

The manufacturing / automation / system integration industry, on the other hand? We’re scared of sharing anything for risk of our competitors seeing what we do. In reality, we could be growing a stronger skill base by talking with others and comparing notes.

aaOpenSource is a way for us to start talking, start sharing, and create community. aaOpenSource is focused on tools, knowledge, and tricks for the Wonderware System Platform (ArchestrA). Check out our GitHub project, poke around, and jump on in. Our hope is that aaOpenSource becomes a little hub of like-minded ArchestrA developers who want to create better things for our customers and make our work lives a little better.

by Gary Mintchell | Sep 4, 2014 | Automation, Data Management, Internet of Things, Operations Management, Software, Technology

The movement in the United States calls it “Smart Manufacturing.” In Germany, you hear “Industrie 4.0” and sometimes “Smart Industry.” Others refer to “cyberphysical systems.” Also involved in this

witch’s brew of ideas is the Internet of Things—also known as Industrial Internet of Things.

The question that matters goes like this, “Is this all just hype perpetrated by academics, government bureaucrats and suppliers looking for something new to sell?”

This is definitely more than a marketing ploy. We are at a technological inflection point where many technologies are coming together. They are often being proven in the consumer economy and then adapted for manufacturing and machine control.

Networks are a fundamental enabler of this new manufacturing technology. As is advanced database technology (aka Big Data) and the analytics that accompany it.

Now we can add advances in smart devices (think your mobile or smart phone and gyroscopes, GPS, temperature sensors, even vibration sensor, and more) that can provide better knowledge of the state of a device. And we have a way to connect that date and use it.

The mobile computing we’ve been using is shortly going to look positively ancient. Let’s try computational embedded T-shirts. Better cameras. Wrist phones. Google (safety)Glass.

Distributed programming is coming into its own. We have IEC 61499 as a start. National Instruments has a programming language (LabVIEW) that is inherently parallel that can exploit the power of multicore processors and FPGAs. There will be more coming from competitors.

Think of the new power machine and operator interface designers have and will have to make things much better. We are at the beginning of a really cool time in manufacturing technology.