by Gary Mintchell | Dec 6, 2016 | Automation, Process Control, Workforce

The war is over and we have won. The war of handheld communication devices loose in the wilds of a plant, that is. Remember only a few years ago–like maybe two–when there was much angst in the media (except from me) about bringing handheld mobile communication into the plant? Now vendors are tripping all over themselves bringing out cool new toys to help maintenance, operations, and engineering do their jobs.

Here is a new tool from ABB. ABB has taken the next step with its Field Information Manager – the first FDI based Device Management tool in the market, with the introduction of its Field Information Manager 1.1 Handheld Edition. This easy-to-use software is now available for sale. The Handheld Edition makes it possible for the user to do configuration, parametrization and diagnosis of the HART instruments in many locations – in the field, at the back of the panel / junction box or in the instrumentation laboratory.

The Field Information Manager is designed to help users be more efficient in the configuration and management of their smart devices. Users do not need to invest in proprietary handheld terminal hardware; this eliminates the extra expense of proprietary hardware and significantly reduces lifecycle maintenance costs. The Field Information Manager can be installed on any Windows tablet / laptop / computer, thereby multiple instrumentation programs can be installed on a single machine. It is very quick to install and saves time for instrument and service technicians. Users can get started in less than three minutes, and can download all needed packages and files at www.abb.com/fieldinfo at any time.

Production technology vendors are really getting wise to the modern world about online stores. Field Information Manager Store and Print device configuration allows easy transfer of parameters from one device to another and eliminates manual recording of parameters.

Other key features of the Field Information Manager Handheld Edition include: Interoperability based on FDI components Online and offline parametrization Documentation of parameters and settings Novel concepts for ease of use and navigation with touch support ABB instrumentation FDI Device Packages ready to download Generic HART Device Package for all HART devices Supports installed base – DD/EDD files Visit www.abb.com/fieldinfo to learn more.

by Gary Mintchell | Jan 20, 2016 | Automation, Internet of Things, Networking, Operations Management

Everyone is in a rush to get an opinion or observation published about the Internet of Things. Evidently it gets lots of page views. Recently other analysts have been publishing thought pieces on IoT in Industry. It appears they have reached the same conclusion that I first broached a couple of years ago. The IoT is not a “thing.” To make any sense of it and use it for any strategy, it must be thought of as an ecosystem encompassing a variety of technologies.

Everyone is in a rush to get an opinion or observation published about the Internet of Things. Evidently it gets lots of page views. Recently other analysts have been publishing thought pieces on IoT in Industry. It appears they have reached the same conclusion that I first broached a couple of years ago. The IoT is not a “thing.” To make any sense of it and use it for any strategy, it must be thought of as an ecosystem encompassing a variety of technologies.

Here is an article that appeared in the Sloan MIT Management Review. Since I am a subscriber, I don’t know if you can see the article at this link.

The writer is Sam Ransbotham is an associate professor of information systems at the Carroll School of Management at Boston College and the MIT Sloan Management Review Guest Editor for the Data and Analytics Big Idea Initiative. He suggests, “The Internet of Things will bring huge changes to the way markets and businesses work — and it could get messy.”

Here is a bromide that I’ve read a thousand times, “Most businesses aren’t ready for the changes to the marketplace that the Internet of Things will bring. But the time to prepare for them is now.”

Actually most business adapt. Some are visionary and will develop new products, processes, and services–and make a lot of money. Others will adapt and survive. Still others will wonder what happened and die. That is the way of business for at least 5,000 years.

Use Case for Internet of Things

“Yes, the potential insights from IoT are enticing. For example, it’s fun to think about the potential personal and even societal benefits from self-driving cars, such as fewer accidents, no problems with parking, more productivity while traveling, car sharing, greater infrastructure efficiency, etc. But perhaps a more profound implication is the data that they can collect. These cars will also be widely distributed “things,” gathering performance data that can help manufacturers diagnose problems, operational data that can help mechanics prevent failures, driver data that can help insurers understand risk, road data that can help cities improve infrastructure, etc. These kinds of insights, we’re ready for.”

But there are a lot more changes coming with the IoT transformation than many people may recognize.

Ransbothem looks into information technology as a model for what will happen in IoT. “About a decade ago, advances in information technology converged to fuel a boom in corporate use of analytics. First, widespread implementation of information systems captured unprecedented amount of data in ways that could be used in isolation or combined. Second, tools and technologies allowed the inexpensive storage and processing. Third, savvy analytical innovators creatively combined these to show everyone else what could be done.”

We have seen all this play out in industrial systems. There remains more to be done, here, though.

He proceeds to look at Internet of Things. “First, the cost and physical size of sensor technology have dropped such that they can be incorporated into most items. Second, widespread communications infrastructure is in place to allow these distributed components to coordinate. Third, once again, savvy innovators are showing the rest of us the possibilities from the data they collect.”

Manufacturing and production are not only poised to exploit these technologies and strategies, they have already been implementing to one degree or another. But his point is valid. IoT needs the ecosystem of sensing devices, networking, communication technology, databases, analytics, and visualization.

Ransbothem identifies four areas of change. Of these, I direct your attention to the last–process changes. I think everything feeds into process changes–not just the processes to make things, but also the information technology, supply chain, and human processes that must not only adapt but thrive with the new information awareness.

- Market Power: IoT should provide a greater amount and a greater value of data, but are companies ready to align their interests in obtaining value from this data with the multiple other companies and end users who create, own, and service the products that originate the data? In the driverless car example, it is easy to see how multiple stakeholders could make use of the data from cars; the same is true for other devices. But it may not be clear who owns what data and how it can be used.

- Complexity: Few organizations are prepared to be hardware and software development companies. But that’s what the Internet of Things will enable. As products are built with embedded sensors, the component mix increases in complexity. As a result, manufacturing systems and supply chains will become more elaborate. Software embedded in products will need to be updateable when the inevitable shortcomings are found.

- Security: If we believe data is valuable, then we need to be ready for people to want to take it from us — why would data be any different than any other precious item? The IoT context intensifies the need for security requirements; for example, sensors or software that allow physical control of the product make attacks easier.

- Process Changes: Many business processes continue to be “pull” oriented. Information is gathered, then analyzed, then decisions are made. This works when change is slow. But with the IoT transition, data will stream in constantly, defying routine reporting and normal working hours. Flooding data from IoT devices will give opportunities for quick reaction, but only if organizations can develop the capacity needed to take advantage of it. Few mainstream large companies are ready for this, much less small- to medium-sized companies that lack the resources of their larger corporate brethren.

The Internet of Things is bringing and will continue to bring advances in how we do business. How well will executives, managers, and engineers execute on this vision? That is key.

by Gary Mintchell | Jan 14, 2016 | Manufacturing IT, Operations Management

Do you know which clouds your company’s files are stored on? Did you even know you had a “shadow IT” problem? This sounds like the problem of the 80s and early 90s when forward thinkers brought PCs into the office because IT took so long to provide information or update reports. Or the past five years as people brought in their tablets and smart phones.

In this case, it’s either the Rolling Stones singing, “Hey! You! Get off of my cloud.” Or maybe Joni Mitchell, “I’ve looked at clouds from both sides now.”

According to Cisco, over the past year unauthorized use of public cloud services has growth 112 percent with the average large enterprise now using 1,220 individual cloud services.

So, Cisco has developed and released Cloud Consumption as a Service. The software discovers and continually monitors cloud usage across an organization and helps organizations reduce cloud risks and costs. It also delivers detailed analysis and benchmarking that helps the IT team proactively manage cloud usage across the organization.

Employees and business groups are increasingly going around IT to get the cloud services they need to do their job. The phenomenon, dubbed shadow IT, is growing exponentially and becoming a major headache for IT leaders. Recent analysis by Cisco reveals the average large enterprise now uses 1,220 individual cloud services. That’s up to 25 times more than estimated by IT. And the average number of cloud services has grown 112 percent over the past year, and 67 percent over the past six months.

Using the new software-as-a-services product, customers can reduce financial and security exposure by identifying risky cloud services, cloud use anomalies, and compliance issues. They can also cut cloud costs by finding ways to consolidate redundant services. Perhaps most importantly, the ability to discover and monitor cloud usage helps IT team better understand the needs of employees and internal teams. When combined with industry benchmarking, this critical information helps IT teams formulate a more strategic cloud strategy for their organization.

Making Educated Decisions on Cloud Services

CityMD is a fast-growing urgent care organization with 50 facilities across New York City and New Jersey. After using Cloud Consumption, CityMD were surprised to discover employees were using nearly 400 cloud services, with IT only formally supporting 15-20.

“Now that we have full visibility into our cloud usage we can make educated decisions about the services that are right for the business and get a better idea of what risks we may face,” said Robert Florescu, vice president of Information Technology at CityMD. “Our company was founded by ER doctors, so they want cloud services fast. With this information at our fingertips we can partner more effectively with our business groups. We can also proactively ensure we have the appropriate security and compliance measures in place.”

From IT Consultant to Business Consultant

To help Cisco improve the new product a number of Cisco partners participated in an early adopter program. Executives at Aqueduct Technologies and World Wide Technology describe the reaction of customers and the potential impact on their business..

“I recently had a conversation with a VP of IT at one of my larger customers. I was able to show him data in the Cloud Consumption dashboard and he was amazed at services he didn’t realize he was using,” said Chris Jennings, the President and chief strategy officer at Aqueduct Technologies—a regional partner based in Boston, Massachusetts. “We then had the opportunity to help them identify public, private and hybrid solutions that can impact their business. Cloud Consumption gives us the insight to transform our relationship from an IT consultant to a business consultant.”

“We want to empower customers to monitor and manage cloud services,” said Jim Melton, the technical architect of the Cloud Practice at World Wide Technology—a national partner headquartered in St. Louis, Missouri. “Cisco Cloud Consumption not only helps with this goal, it also provides insight to help define the next steps in a customer’s cloud journey, and concrete data to build the business case for their cloud initiatives. Cloud Consumption is helping us move from a product-centric conversation to a solutions-oriented, business outcome approach with our customers.”

Price and Availability

The new Cisco Cloud Consumption as a Service is now available globally via qualified Cisco channel partners. The new service costs approximately $1-2 dollars per employee per month, depending on the size of the business.

by Gary Mintchell | Jan 13, 2016 | Automation, Events, News, Operations Management

We are closing in on February and time to start thinking about the ARC Industry Forum in Orlando. I went to my first one in 1998 and have my airline and hotel reservations for this edition.

We are closing in on February and time to start thinking about the ARC Industry Forum in Orlando. I went to my first one in 1998 and have my airline and hotel reservations for this edition.

Given the demise of general industry trade shows, there are precious few opportunities to see a large cross section of the automation and control industry. This is one.

I have 2 or 3 appointments set. If you are there, ping me. Maybe we can do a “meet up” in the lounge before everyone splits for dinner or something. Or stop me to chat during the week. ARC has once again planned an afternoon of press conferences for its sponsors. I’ll arrive in time to listen if you are presenting.

The 20th Annual ARC Industry Forum has the theme, “Industry in Transition: Navigating the New Age of Innovation”.

The conference is February 8-11, 2016 at the Renaissance Sea World in Orlando, Florida.

ARC says, “New information technologies such as Industrial Internet of Things (IIoT), Smart Manufacturing, Industrie 4.0, Digitization, and Connected Enterprise are ushering in a new age of innovation. These concepts are clearly moving past the hype, where real solutions are emerging backed by strong business cases. Expect to see innovations in smarter products, new service and operating models, new production techniques, and new approaches to design and sourcing. Join us to learn how this industrial transformation will unfold and what other companies are doing today to embrace innovation and improve their business performance.”

Questions they expect to address:

- How will inexpensive, easy-to-install sensors change existing products and plants?

- Will cyber security concerns impede disruptive innovation?

- What kind of intelligence will machines have and what value will this bring?

- What role will Wi-Fi and LTE play?

- How do Big Data and predictive and prescriptive analytics enable operational change?

- What is the opportunity in aftermarket services?

- What software capabilities are needed to achieve transformational change?

- Which industries are already changing?

- What steps can organizations take to foster innovative thinking?

Forum’s Keynote Presentations

Michael Carroll, Vice President, Innovation & Operations Excellence, Georgia-Pacific

Michael joined Georgia-Pacific in 2010 to focus his technological and entrepreneurial talents on innovation and leadership. Prior to that he and a partner formed McTech Group, a company focused on innovative products for the building products and construction industry. In addition to his Executive Vice President responsibilities, Michael formed a Joint Venture designed to sell consumer “DIY” products to big box retailers like Wal-Mart, Home Depot, and Lowe’s. Previous positions include Director of Operations at Riverwood International, CEO of North and South American Operations at Shepherd, and Principal Change Agent at Mead Paper.

Sandy Vasser, Facilities I&E Manager, ExxonMobil Development

Sandy has been with Exxon or ExxonMobil for over 35 years and has been involved in a number of Upstream projects covering offshore facilities, onshore facilities, and cogeneration facilities. He currently manages a team of about 120 electrical and I&C professionals responsible for the design, installation, and commissioning of electrical generation and distribution systems, process control systems, and safety instrumented systems for all major ExxonMobil Upstream capital projects. This team is also responsible for developing, promoting and implementing strategies, practices, processes, and tools for successfully executing project automation and electrical activities.

Rob High, Vice President and Chief Technology Officer, Watson Solutions, IBM Software Group

Rob has overall responsibility to drive Watson Solutions technical strategy and thought leadership. He works collaboratively with the Watson engineering, research, and development teams across IBM. Prior to joining Watson Solutions, Rob was Chief Architect for the SOA Foundation and member of the IBM Academy of Technology. He championed an open industry architectural definition of the principles of business and IT alignment enabled by SOA and business process optimization, as well as ensuring IBM’s software and services portfolio is architecturally grounded to enable for efficient SOA-based solutions. Rob has 37 years of programming experience and has worked with distributed, object-oriented, component-based transaction monitors for the last 26 years.

by Gary Mintchell | Jan 11, 2016 | Asset Performance Management, Automation, Internet of Things, Operations Management, Technology

Remote monitoring and diagnostics is a key driver for the Internet of Things strategy adoption in manufacturing and production. Advances in both the technology and services involved in this area appears to be the area of best economic return these days.

Remote monitoring and diagnostics is a key driver for the Internet of Things strategy adoption in manufacturing and production. Advances in both the technology and services involved in this area appears to be the area of best economic return these days.

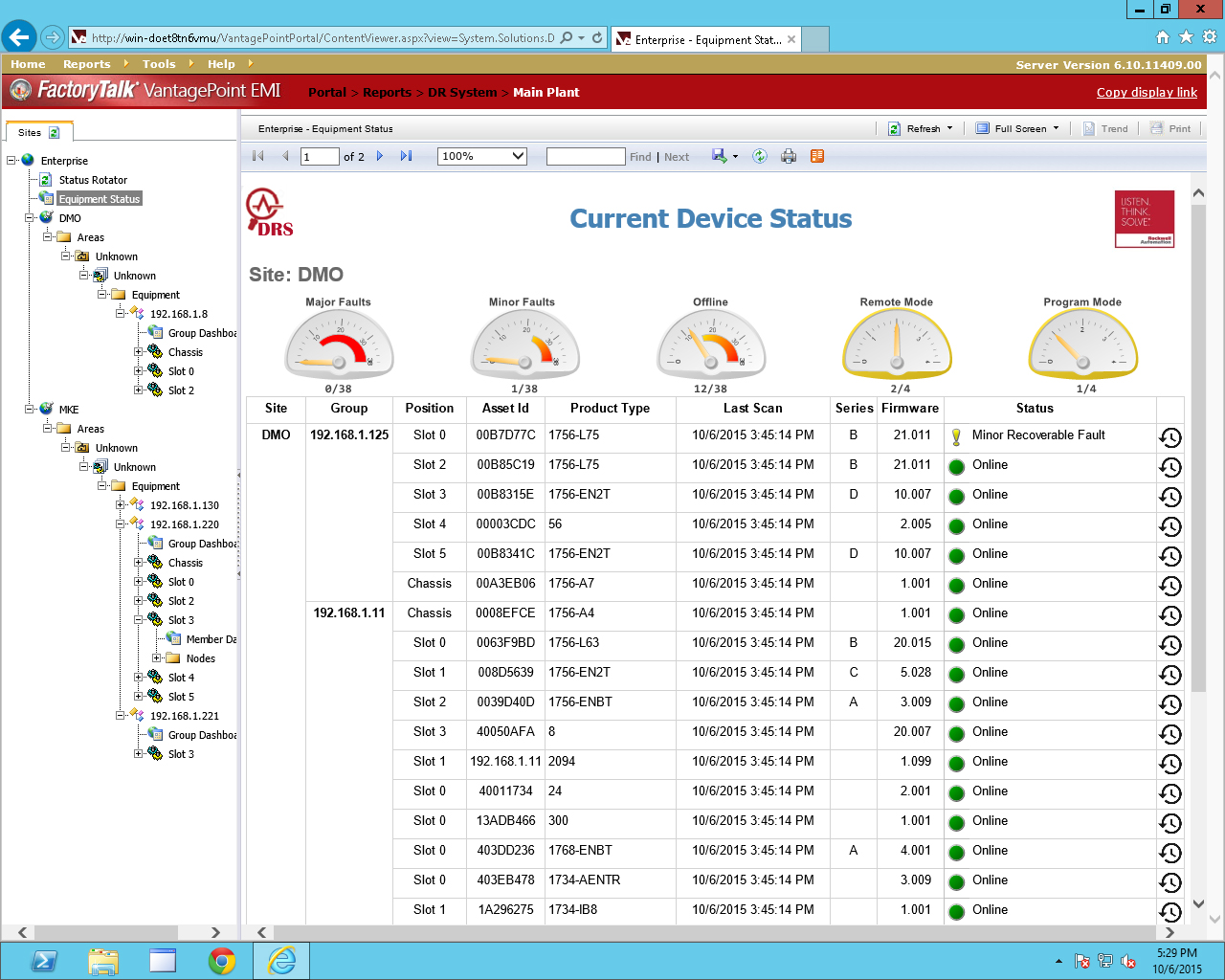

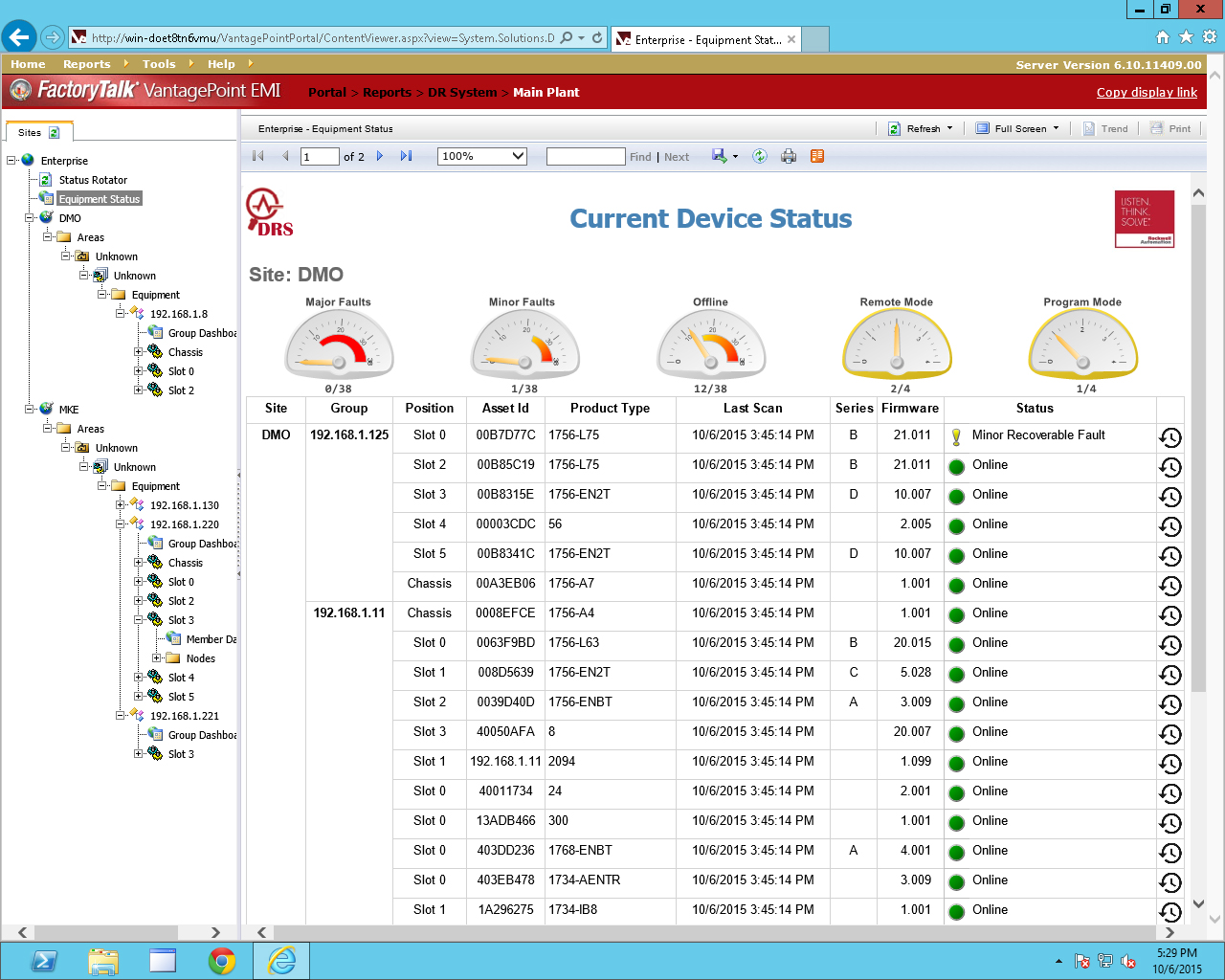

Rockwell Automation recently released news about its take on a diagnostic reliability service. Rockwell doesn’t tie it to the Internet of Things, much to its credit. But this solution fits within the broad trend I’ve seen developing.

The solution deploys a layer of technology across plant devices and equipment to monitor and perform analysis, and create a continuous improvement approach to reliability maintenance, reducing operational risk. As part of the service, a Rockwell Automation domain service expert also closely tracks equipment performance to advise on reliability improvements to the production facility.

“Our customers have access to a huge amount of data within their assets, but they often struggle to turn data into useful operational intelligence,” said Ryan Williams, product manager, Rockwell Automation. “In the past, companies relied on maintenance personnel on-site to check the status of equipment in the field and then develop corrective action plans. Now, with the diagnostic reliability service, they can transform maintenance data into asset intelligence. This helps build a more Connected Enterprise, leveraging interconnected data systems and producing actionable information. Companies can better prioritize choices on maintenance and production, and do more with less.”

The solution automatically collects identity and health data from all networked devices on the production control network. The data is then modeled with asset management information to trigger events and send alerts to necessary personnel for proactive maintenance. With the service, Rockwell Automation asset reliability professionals assist users in applying the intelligence on their critical equipment to inform data-driven maintenance decisions and increase productivity.

Case in diagnostics

Case in point: A major oil and gas company used the diagnostic reliability solution to help centralize information gathering and monitor hundreds of critical control assets across a California rural valley. The company also needed inventory of all the field devices in its process control network for a companywide cybersecurity policy. The automated identification and monitoring solution helped the company’s California business unit comply with the new corporate policy, reduce costs associated with field service manpower through proactive maintenance, and increase its daily oil production.

Through integrated, automated device identification and tracking, other customers using the diagnostic reliability service can realize approximately 70 percent reduction in manual data-collection time.

The diagnostic reliability offering is applicable to all manufacturers, with an industry emphasis including oil and gas, mining metals and cement, auto tire and rubber, and consumer packaged goods.

Everyone is in a rush to get an opinion or observation published about the Internet of Things. Evidently it gets lots of page views. Recently other analysts have been publishing thought pieces on IoT in Industry. It appears they have reached the same conclusion that I first broached a couple of years ago. The IoT is not a “thing.” To make any sense of it and use it for any strategy, it must be thought of as an ecosystem encompassing a variety of technologies.

Everyone is in a rush to get an opinion or observation published about the Internet of Things. Evidently it gets lots of page views. Recently other analysts have been publishing thought pieces on IoT in Industry. It appears they have reached the same conclusion that I first broached a couple of years ago. The IoT is not a “thing.” To make any sense of it and use it for any strategy, it must be thought of as an ecosystem encompassing a variety of technologies.

We are closing in on February and time to start thinking about the

We are closing in on February and time to start thinking about the

Remote monitoring and diagnostics is a key driver for the Internet of Things strategy adoption in manufacturing and production. Advances in both the technology and services involved in this area appears to be the area of best economic return these days.

Remote monitoring and diagnostics is a key driver for the Internet of Things strategy adoption in manufacturing and production. Advances in both the technology and services involved in this area appears to be the area of best economic return these days.