by Gary Mintchell | Nov 29, 2016 | Internet of Things, News, Operations Management, Organizations, Standards

IIoT Business Model

In another advancement for the Industrial Internet of Things, The Industrial Internet Consortium (IIC), the global, member-supported organization that promotes the accelerated growth of the Industrial Internet of Things (IIoT), announced the publication of the Business Strategy and Innovation Framework (BSIF). The BSIF helps enterprises to identify and analyze issues that must be addressed to capitalize on the opportunities emerging within the IIoT.

“Everybody knows that the Industrial Internet of Things will completely transform the way that business works. What’s not clear is exactly how to deploy these new IIoT concepts to best effect,” said Jim Morrish, Chair of the Business Strategy Task Group, and Founder and Chief Research Officer, Machina Research. “What the IIC’s Business Strategy and Innovation Framework provides is a toolkit for identifying, prioritizing and initiating the deployment of those crucial IIoT initiatives. It’s a significant step forward for the IIoT industry in terms of working to capitalize on the huge opportunities presented by this new technology wave.”

The BSIF serves as a reference document for chief executives in enterprises planning to engage in IIoT concepts. A single-source compendium of the issues and challenges enterprises should consider before they deploy IIoT initiatives, the BSIF details frameworks and concepts to help enterprises increase value for users, customers and partners while at the same time helping to reduce market and technical uncertainties.

The BSIF outlines a comprehensive set of best practices for companies engaging in IIoT, but companies are free to adopt a lighter touch or use an existing internal project model, especially within smaller companies. Alternatively, a range of project support processes may already be in place and the approach documented in the BSIF may be used to enhance existing infrastructures to address new IIoT opportunities (particularly for larger companies).

“The IIC’s Business Strategy and Innovation Framework is an important industry milestone,” said Jim Nolan, EVP, IoT Solutions, InterDigital. “It offers timely, strategic guidance to the many organizations that are beginning to implement IIoT solutions.”

The BSIF is the most in-depth Industrial IoT-focused business strategy framework comprising expert vision, experience and business strategy best practices from IIC members, including Bosch Software Innovations, InterDigital, Hewlett Packard Enterprise, and Machina Research. The BSIF is available free of charge. For more information about the BSIF, click here.

The Business Strategy and Innovation Framework provides a high-level identification and analysis of issues that any enterprise will need to address to capitalize on the opportunities emerging from this current revolution that is the IIoT. This comprehensive document is a product of the Business Strategy Task Group, a strategy-focused task group within the Industrial Internet Consortium’s Business Strategy and Solution Lifecycle Working Group.

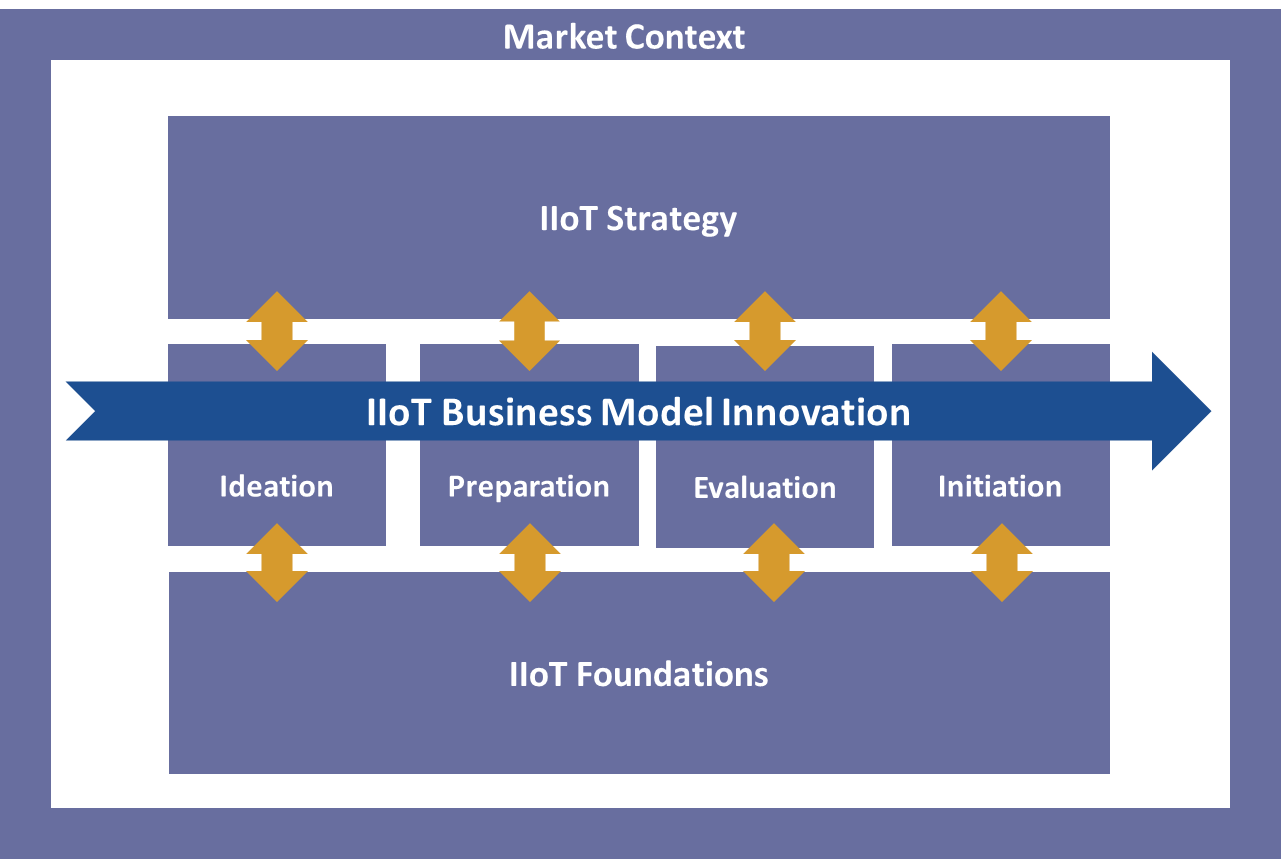

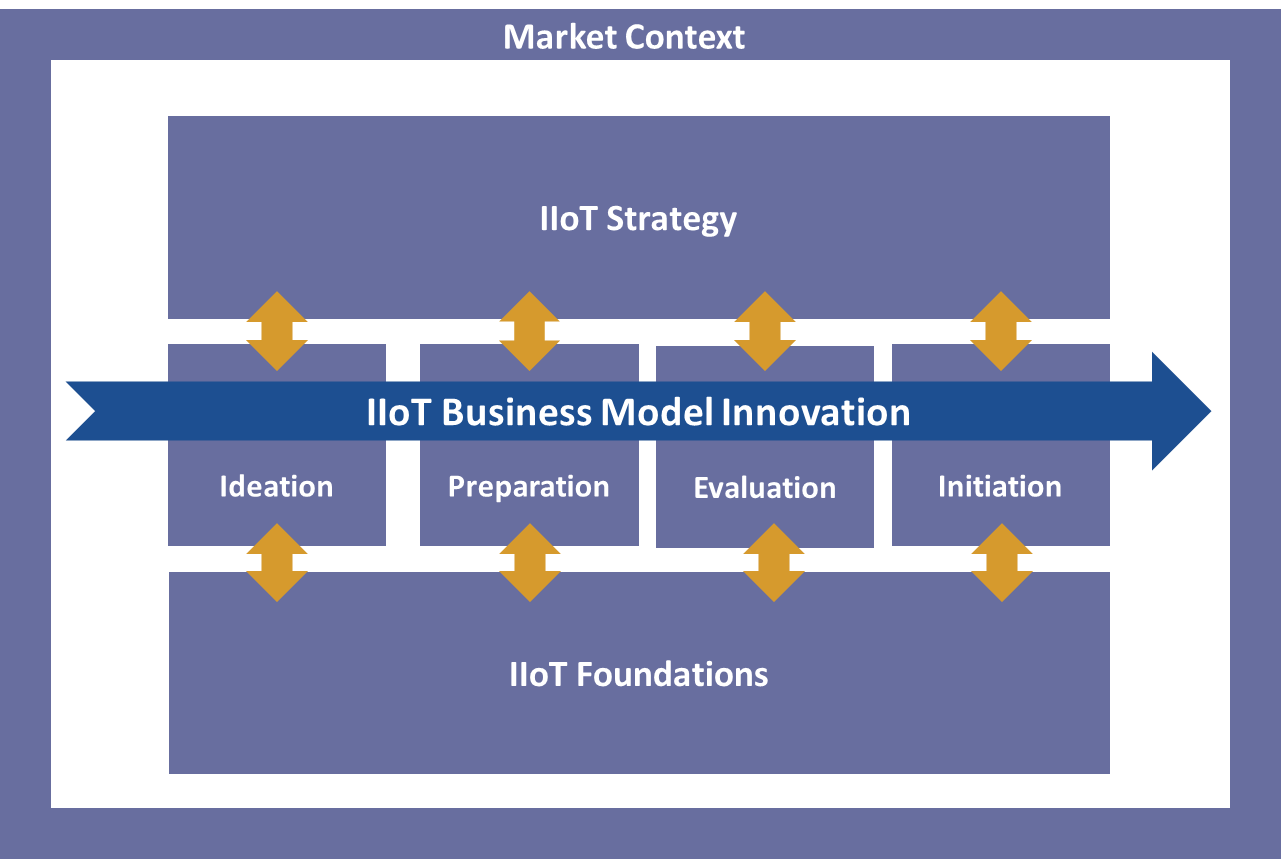

The Business Strategy and Innovation Framework describes the requirements to succeed in IIoT:

- An IIoT strategy and goals

- A structured framework to target and select the right IIoT opportunities

- A system in place to identify, assess and initiate IIoT opportunities

IIoT requires enterprises to rethink their current business models. This is necessary regardless of whether they actually adopt IIoT solutions internally: Industry is moving toward IIoT adoption, and enterprises that keep pace with this trend will undoubtedly have a strong competitive advantage.

Contributors to the Business Strategy and Innovation Framework dedicated their valuable time and expertise in authoring, editing and other ways. In particular, we would like to thank the following contributing members and their organizations:

- Veronika Brandt – Bosch Software Innovations

- Ken Figueredo – InterDigital, Inc.

- Steve Haldeman – Hewlett Packard Enterprise

- Jim Morrish – Machina Research, Chair of the Industrial Internet Consortium Business Strategy Task Group

by Gary Mintchell | Nov 22, 2016 | Automation, Manufacturing IT, Networking, News, Technology

Last week was GE Digital’s Minds + Machines Conference in San Francisco. This Industrial Internet (or Internet of Things to the rest of us) gathering showcases the latest of GE’s digital portfolio–including GE Automation and Control (the successor to GE Intelligent Platforms, successor to GE Fanuc Automation, whew).

Jim Walsh

Rich Carpenter

I tried to arrange my schedule to make it out there, but there had been too many trips in Sept., Oct., and Nov. for my time and expense budget to make it. So, we had a conference call meeting with Jim Walsh, President and CEO of GE Automation & Controls, and Rich Carpenter, Product GM of Control Platforms also at GE Automation & Controls. We talked about the Industrial Internet, digitalization, and new products.

Included in my news below are additional news from the M+M event including acquisition and product news.

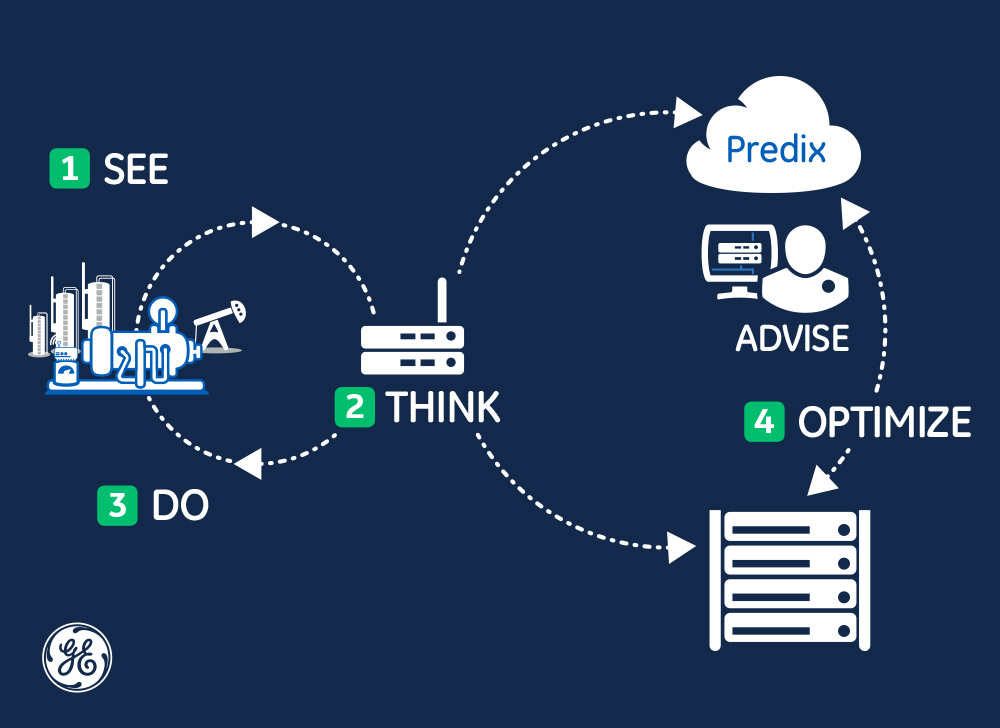

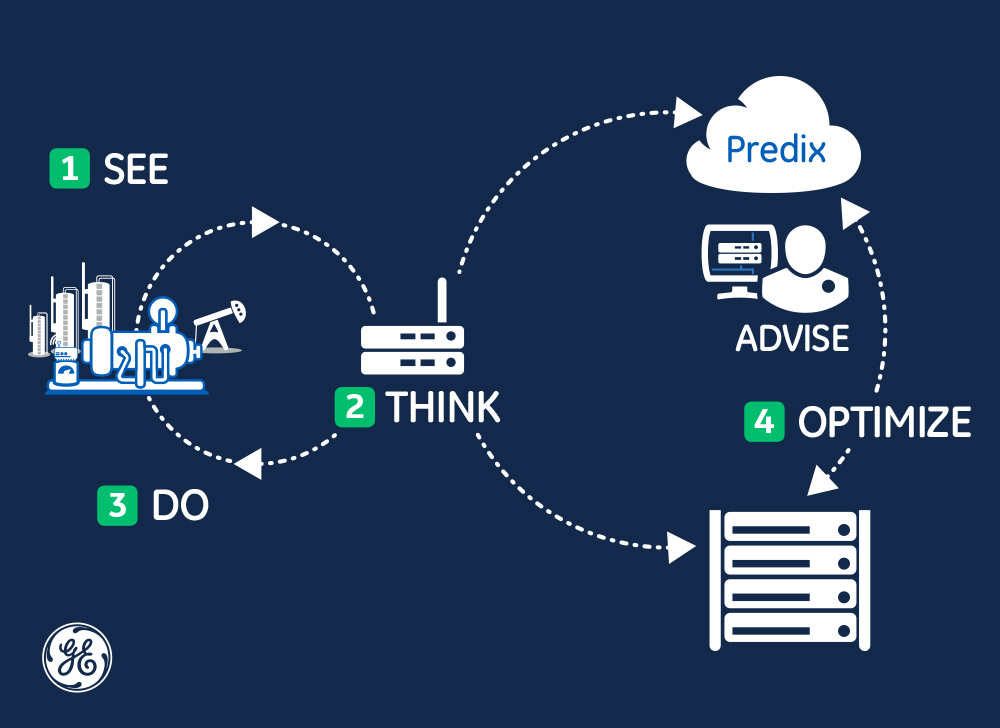

The point most interesting was Walsh and Carpenter discussed the edge device of the network as the controller (PLC). (See the graphic) Almost all of the other companies I talk with are developing an edge device separate from the controller. Carpenter described the closed loop control as “see-think-do”, and then the Industrial Internet plus Predix (GE’s cloud-enabled software product) analytics adds an “optimize” loop to the controller. It can then reflect back on experience and make changes as necessary.

Take for example large pumps in a water/wastewater application. They, of course, are energy consumers. By adding analytics from Predix, the controller could be modified to operate in a more energy efficient manner. One example proved out a $1.5 million per year savings. Another benefit is productivity improvements which Walsh said they had witnessed personally. They referred to the Industrial Internet Control System (IICS), which I will discuss later [Note: much like my Automation Fair update, this one will be long, because there is so much.]

And now, on to the news.

- GE releases new suite of Predix applications and services; introduces the Predix System

- Acquisition of Bit Stew Systems enables efficient data ingestion for industrial applications

- Acquisition of Wise.io strengthens machine learning and data science capabilities for Predix and enables enhanced Digital Twin development

- Meridium acquisition places GE in the lead for Asset Performance Management app development; acquisition of ServiceMax positions GE to lead in service transformation

- Ecosystem expands with independent software vendor program to speed industrial application development; more than 19,000 developers now building on Predix

- Digital orders on track to exceed $7B, a growth of 25%+ in 2016

- Digital thread productivity exceeds $600 million and accelerating into 2017

In 2016, orders from GE’s portfolio of software solutions are on track to climb 25%+ to more than $7 billion. Demonstrating the strength of Predix within GE, digital thread productivity will exceed $600 million, accelerating into 2017.

“The opportunity for industry is now,” said Bill Ruh, Chief Digital Officer of GE and CEO, GE Digital. “The Industrial Internet is profoundly transforming how we operate and our ability to deliver greater productivity for GE and for our customers. Connected machines, coupled with deep machine learning, are more powerful than anything we have seen. These strategic investments in both the Predix platform and our partners continue to attract industrial companies and provide them with tools they need to embark on their own digital industrial transformations.”

EXTENDING PREDIX FROM THE EDGE TO THE CLOUD

GE unveiled a new suite of software and applications.

This release will focus on expanding the platform and scaling development of Digital Twins – virtual representations of physical assets that comprise the world’s industrial infrastructure – through Predix apps and toolkits.

This new set of components can run on a variety of operating systems, devices and form factors – from sensors and controllers to gateways, server appliances and the cloud – making Predix a distributed system for the Industrial Internet and a complete “edge-to-cloud” offering.

GE also launched new Predix-based solutions, designed to help customers harness the power of the Industrial Internet:

Current, designed to analyze and optimize energy use and operational efficiency use across lighting, HVAC and other systems.

Digital Substation, extends maintenance optimization to the electricity grid.

Health Cloud, Cloud-enabled patient outcomes are linking clinical feedback to transformative radiology pathways.

Predictive Corrosion Management, a new Asset Performance Management (APM) solution that provides continuous inspection data and cloud-based analytics of pipe conditions to help operators manage corrosion-related risk.

Digital Power Plant software for gas, steam and nuclear plants, which features new tools to help customers reduce unplanned downtime by up to 5%, reduce false positive alerts by up to 75%, and reduce operations and maintenance costs by up to 25%.

Digital Hydro Plant, a suite of apps combining both software and hardware solutions designed to support Hydro customers globally, helping them get the most out of assets over the lifetime of a plant.

ACQUISITIONS

GE Digital announced it has acquired Bit Stew Systems to bring its data intelligence capabilities to Predix and other industrial solutions. Bit Stew applies its machine learning and artificial intelligence (AI) capabilities to automate the process of data modeling, mapping and ingestion, accelerating time to value for customers, such as BC Hydro, Pacific Gas & Electric and Scottish & Southern Energy. This acquisition will help GE Digital provide a solution to organize large amounts of data through efficient data organization at the edge or at the source of the data – the asset.

GE Digital also acquired Wise.io, a leading machine learning and intelligent systems company. This acquisition will enable GE Digital to further accelerate development of advanced machine learning and data science offerings in the Predix platform. The Wise.io team deepens GE’s machine learning stack and will spearhead innovative solutions in GE’s vertical markets to develop its machine learning offerings.

GE also announced a program dedicated to independent software vendors (ISVs), aimed at spurring development of industrial solutions and extending the reach of the Predix platform. Through these partnerships, GE will share its industry expertise and allow partners to use Predix as the building block for new industrial applications to enhance various components of industrial operations – such as maintenance, content development and asset management.

Inaugural launch partners include: Box, Decisyon App Composer, Entercoms, Ericsson, Mobideo, Nurego, OAG Analytics, Pitney Bowes and Splunk. The addition of ISVs enhances the growing ranks of the GE Digital Alliance Program, which launched in February. The alliance program now boasts more than 270 partners around the world, including major enterprise players such as AT&T, EY, Intel, Microsoft and Tata Consultancy Services (TCS).

GE’s Industrial Internet Control System

GE’s Automation & Controls business introduced GE’s new Industrial Internet Control System (IICS) at its 2016 Connected Controls Symposium at the company’s Global Research Center in Niskayuna, NY. IICS delivers new levels of productivity for industrial assets and processes by integrating controls with Industrial Internet analytics – at scale yet modular and flexible for industrial settings worldwide.

Early IICS adopters report a +7% gain in asset performance and 22% increase in efficiency. By leveraging GE’s deep domain and controller expertise, the IICS solution empowers customers to improve operational efficiency, optimize production and unlock new revenue opportunities.

The system utilizes GE’s Field Agent technology as the gateway between the asset and the Industrial Internet. Field Agent provides a rugged, pre-configured solution for secure data collection and conveyance from the machine to fuel analytics that improve operations.

GE’s Industrial Internet Control System also includes:

- Industrial Cloud Platform – Provides real time process optimization and control; minimalizes disruption to deployed application; Creates new value over time without having to retrofit

- Secure Cloud Connectivity – Predix ready; Provides secure data collection; Enables advanced analytics; Form factors to meet the need

- Outcome Optimizing Controllers – Real-time control; Defense in-depth security; Decreases time to market; Helps reduce unplanned downtime and enhance system performance

- Mix & Match I/O – Remote, real-time diagnostics; Wide range of communication options; Modularity-simple scalability; Drives improved availability and simplified maintenance

- Professional Services – Real Time control; Security at its core; Decreases time to market; Helps reduce unplanned downtime and enhance system performance

- Intelligent Apps – Real Time Control; Security at its core; Decreases time to market; Helps reduce unplanned downtime and enhances system performance

IICS features dual or quad core configuration which provides safe and secure communication with either cloud-based or locally hosted algorithms and applications.

Two structural innovations make the new solution “future proof” for customers, who want hardware assets to be long-lived but remain optimally functioning.

- Industry-first Hypervisor control technology that separates operations from software so that the software can be upgraded without affecting the physical controller, allowing the hardware to stay in place and up to date.

- ComExpress processor technology that allows the processor to be updated as needed, again without replacing the controller. This is critical to support the growing computational power available from the Industrial Internet, including GE’s Digital Twin predictive model for optimizing assets with minimal interruption.

by Gary Mintchell | Nov 8, 2016 | Internet of Things, News, Operations Management, Organizations

The Industrial Internet Consortium has been consistently in the news lately. Members have been added and testbeds established. Here is another announcement furthering the cause of collaboration, and one hopes, interoperability in the Internet of Things (IoT) space.

The Industrial Internet Consortium (IIC), the global, member supported organization that promotes the accelerated growth of the Industrial Internet of Things (IIoT), announced it will collaborate with the IoT Acceleration Consortium (ITAC) to further the development of Internet of Things (IoT) in numerous industries.

The goals of the cooperation are to promote the digital economy by preventing fragmentation and to harmonize various aspects of IoT. Joint activities will include: · Identifying and sharing best practices · Collaborating on test beds and research and development projects · Realizing interoperability by harmonizing architecture and other elements · Collaborating on standardization · Other activities to which both parties agree

“We were delighted to sign the Memorandum of Understanding with the IoT Acceleration Consortium,” said Dr. Richard Soley, Executive Director of the Industrial Internet Consortium. “Both consortiums share mutual goals and we look forward to working closely with ITAC on testbeds and research and development projects to advance the adoption of the industrial Internet.”

The IoT Acceleration Consortium (ITAC) aims to combine the strengths of government, industry, and academia to build a structure for developing and demonstrating technologies related to the promotion of Internet of Things (IoT). It also aims to create and facilitate new business models. ITAC promotes the development, demonstration, and standardization for IoT-related technologies and the creation of various IoT-related projects and recommendations required to run those projects.

The Industrial Internet Consortium (IIC) is a global, member supported, organization that promotes the accelerated growth of the Industrial Internet of Things by coordinating ecosystem initiatives to securely connect, control and integrate assets and systems of assets with people, processes and data using common architectures, interoperability and open standards to deliver transformational business and societal outcomes across industries and public infrastructure. The Industrial Internet Consortium is managed by the Object Management Group (OMG).

by Gary Mintchell | Oct 28, 2016 | Automation, Internet of Things, News, Operations Management

Emerson Automation (formerly Emerson Process Management) is the latest automation company to thoroughly exploit the Industrial Internet of Things as it unveiled its digital strategy and reinvigorated Plantweb architecture at Global Users Exchange 2016.

Microsoft continues its deep penetration into industrial and manufacturing automation markets with a renewed commitment from Emerson. The companies announced at Exchange the Plantweb digital ecosystem and Connected Services are powered by Microsoft Azure IoT Suite.

Emerson is also broadly adopting Microsoft’s Windows 10 IoT technology both in its DeltaV and Ovation control systems and in data gateways.

First introduced as the industry’s most advanced process control and safety network, Plantweb now harnesses the power of Industrial IoT to expand digital intelligence to the entire manufacturing enterprise, while also providing an architecture for on-premise applications. Plantweb provides a comprehensive framework to help manufacturers achieve Top Quartile performance in the areas of safety, reliability, production and energy. Top Quartile is defined as achieving operations and capital performance in the top 25 percent of peer companies.

“In 1997, Emerson revolutionized the automation landscape with Plantweb, the first field-based digital plant architecture,” said Peter Zornio, chief strategic officer, Emerson Automation Solutions. “Now, we are doing it again by harnessing the power of Industrial IoT to give customers the technology foundation for Operational Certainty.”

The pieces comprising Plantweb (see diagram) include (from the bottom of the stack): Pervasive Sensing; Secure First Mile; Insight; Advisor; Always Mobile; and, Connected Services. I’ll discuss a little of each of these below. Many are build outs of existing products and technologies, some are new products or services.

Pervasive Sensing

Emerson’s Pervasive Sensing Strategies expand the use of sensor and analytics technology into new operational performance areas through a new generation of low-cost sensors that are easy to install and maintain, take advantage of wireless communications as part of a secure, integrated industrial network and use new analytic algorithms to create insights into the performance of a plant’s assets.

Emerson’s expanding portfolio of pervasive sensing technologies includes capabilities in the areas of hazardous gas sensing, wireless corrosion monitoring, wireless medium voltage equipment monitoring, wireless gas monitoring, wireless non-intrusive surface-sensing temperature measurement, wireless power metering and pressure gauge measurement.

Wireless corrosion monitoring

Emerson’s Permasense Wireless Corrosion Monitoring is a permanently-installed technology that uses unique sensor technology, wireless data delivery and advanced analytics to continuously monitor for metal loss from corrosion or erosion in pipes, pipelines or vessels.

Designed to operate without maintenance for years, this monitoring technology reliably delivers high-integrity data even in the harshest environments, providing ongoing visibility of corrosion and erosion trends in real-time and direct to the engineer.

Wireless medium voltage equipment monitoring

Emerson’s IntelliSAW wireless medium voltage equipment monitoring systems offer real-time, continuous monitoring of electric power switchgear temperatures and smart grid monitoring, providing accurate temperature data for key points in a power transmission network.

Wireless gas monitoring

Emerson’s Rosemount 928 Wireless Gas Monitor is the world’s first integrated WirelessHART toxic gas detection solution. Maintaining remote sites like wellheads and natural gas metering stations is difficult and dangerous because workers approaching these sites may be exposed to unplanned releases of toxic gas. Due to the prohibitive costs to install and operate conventional gas detection systems at these sites, operators have been forced to rely on portable gas detection devices or, even worse, carry on with no gas detection at all. In all these cases, workers may run the risk of exposure when approaching these remote sites to perform maintenance.

Wireless non-intrusive surface-sensing temperature measurement

Emerson’s Rosemount X-well Technology is a surface-sensing temperature measurement solution that eliminates the need for thermowell process penetration when measuring process temperatures in pipe applications and removes leak points to reduce compliance costs and increase safety. X-well technology eliminates the need to drill device connections to get process temperatures, allowing users to avoid the risk of corrosion.

Wireless power metering

The Emerson SensEnable 56WM wireless power meter is designed to monitor voltage, current, power, energy, and other electrical parameters on single and three phase electrical systems with revenue-grade accuracy. The power meter delivers early detection of machine problems through continuous measurement of power consumption and power quality of submeters. Submeters are physical metering devices that monitor electricity, gas, water, steam, and other utilities.

Pressure gauge measurement

Emerson’s Rosemount Wireless Pressure Gauge delivers safer and more reliable readings, enabling remote collection of field data as frequently as once per minute. Accurate, wireless readings keep operators updated on changing field conditions remotely – reducing manual operator rounds and improving safety by keeping personnel out of hazardous areas and safeguarding against catastrophic events.

Secure First Mile

Emerson’s Secure First Mile is a set of architectural approaches and designs, enabled by a family of security services and robust, secure and flexible servers, gateways, and data diodes that ensures that data in existing OT systems can be easily and securely connected to internet based applications.

Using Secure First Mile architectures, a plant can transform its operational technology data into information technology data while ensuring outbound paths of information do not become inbound paths that expose its systems to harm.

As part of its Secure First Mile architectures, Emerson is using OPC Unified Architecture (UA) servers to export data from application databases. OPC UA is an industrial machine-to-machine communication protocol that can be directly consumed by Microsoft Azure, Emerson’s chosen platform for cloud computing. Microsoft Azure enables the building, deployment and management of applications and services through a global network of Microsoft-managed data centers. Its integrated cloud services include analytics, computing, database, mobile, networking, storage and web applications.

To connect its field data aggregation products such as wireless sensor gateways, CHARM I/O cards, Ethernet I/O cards and RTUs, Emerson is using Windows10 IoT edge gateways. These gateways enable data to securely reach the Microsoft Azure cloud by translating operational technology protocols such as FOUNDATION fieldbus (FF) and HART to information technology protocols such as Advanced Message Queuing Protocol (AMQP) & MQ Telemetry Transport (MQTT). These gateways provide a high degree of security through data encryption and key management. In addition, as described, data diodes installed within the system act as physical barriers to incoming information, preventing outside access to a plant’s systems.

Insight

Emerson’s Plantweb Insight applications, which leverage Emerson’s Pervasive Sensing strategies, help users instantly make sense of plant data to drive overall enterprise profitability. It’s a single, lightweight, easy-to-install web-based platform that automatically and strategically interprets plant data through a scalable suite of applications.

Plantweb Insight features a user-friendly, intuitive interface capable of running on any device with access to a web browser (desktop computers, laptops, tablets and mobile phones). Pre-built analytics require minimal configuration, and its flexible software is operating system-independent, easily installing and integrating with existing infrastructures.

The power of Plantweb Insight resides in its collection of easy-to-deploy applications, each containing the embedded domain expertise and analytics that enable existing resources to immediately identify and resolve asset issues that historically were addressed by periodic, manual rounds or unexpected failures. These applications are designed to help users realize the most from Pervasive Sensing strategies at their sites.

More than a dozen total applications are scheduled for release, with each dedicated to a single, specific asset class. The first three applications are available now and future applications will be released at a rate of two per quarter.

Plantweb Insight is currently available with applications for steam trap monitoring, pump monitoring and pressure gauge monitoring.

Advisor

Emerson’s Plantweb Advisor Suite is a scalable set of software products offering two new applications, Health Advisor and Performance Advisor, in addition to the previously released Energy Advisor – all of which leverage the industry-standard OSIsoft Pi System’s highly scalable open data infrastructure that captures and shapes data generated by equipment.

“Together, Emerson and OSIsoft are creating a foundation for digital transformation,” said Martin Otterson, senior vice president of sales, marketing and partners at OSIsoft. “Through the combination of Plantweb Advisor Suite and the PI System, organizations will be able to rapidly achieve deep insights into their operations that in turn will help them boost productivity or develop new services.”These complementary applications are designed to boost operational performance by empowering a plant’s reliability, process and energy experts with critical information about equipment health and efficiency as well as energy consumption and emissions.

Using the Plantweb Advisor Suite, a plant’s essential assets are continuously monitored for potential problems with Health Advisor, operating efficiency of a plant’s equipment is tracked through Performance Advisor, and Energy Advisor maps and manages a plant’s energy consumption in real time.

Always Mobile

Always Mobile solutions deliver secure, instant access to critical information in intuitive views that prepare personnel at all levels to more effectively make business-critical decisions and operate their facilities.

AMS Asset View

AMS Asset View software is a dashboard and messaging application used to present asset health information on desktops, laptops, and mobile devices. An application connecting into the AMS ARES Platform, AMS Asset View’s persona-based views ensure that reliability personnel know the health of their assets in relevant time and always see the alerts they need to see, and only the alerts they need to see, so they can focus on asset conditions critical to production.

AMS Asset View focuses on delivering asset health status and alerts in relevant time, using a push alert mechanism to provide notifications that are pertinent to a user’s responsibilities and the criticality of an individual asset.

DeltaV Mobile

The new DeltaV Mobile application allows process engineers, operators, and plant managers to quickly and easily view personalized watch lists and receive real-time alarm notifications.

Collaborative features enable users to more efficiently diagnose and troubleshoot abnormal process situations—whether they are on site or in a remote location.

Guardian Mobile

Emerson announces Guardian Mobile, a mobile application delivering visibility of critical data for control, asset, machinery, and device monitoring systems. An element of Emerson’s Always Mobile, Guardian Mobile enables users to access their system health score for all associated systems from anywhere.

AMS Trex Device Communicator

The AMS Trex Device Communicator is a handheld communicator for advanced diagnostics, configuration, and troubleshooting in the field, designed to improve the efficiency of the many tasks performed by maintenance technicians.

The Trex communicator supports additional mobile applications, such as ValveLink Mobile, which allows technicians to configure and test valves inline, minimizing the impact on production.

Connected Services

Emerson Connected Services are bridging that gap by harnessing the Industrial IoT to help its customers maximize the health, reliability and performance of plant assets and processes through proactive, predictive analysis that delivers actionable data. A key component of Emerson’s Plantweb digital ecosystem, the service offers remote, continuous assessment of a plant’s equipment and processes by Emerson experts to empower customers with the information needed to improve efficiency and avoid unplanned downtime. Emerson Connected Services utilize Microsoft Azure cloud services and data analytic tools that provide a scalable and secure cloud application environment.

Emerson Connected Services offer support across four main subscription-based service offerings in which experts analyze data from critical equipment to provide actionable insights so customers can align their maintenance and operational responses with their business strategies. These offerings currently include Control Valve Connected Services, Steam Trap Connected Services, DeltaV System Health Connected Services, and Machinery Connected Services.

These new services are an integrated part of Emerson’s Lifecycle Services offerings, enabling Emerson to provide customers with more effective and efficient access to its experts. Rather than physically sending experts to inspect and analyze data from critical equipment on a customer’s site, Emerson is able to bring the data to the experts, wherever they are located, with secure connectivity and cloud services. For the most part, users are leveraging the existing infrastructure in their facility making it easy to start small and focused, and grow the service to deliver more business results.

by Gary Mintchell | Oct 26, 2016 | Automation, Internet of Things

Figuring out how to assemble the pieces of the Industrial Internet of Things, the Industrial Internet Consortium promotes testbeds where collaborating companies can work out proof of concept.

National Instruments, SparkCognition, and IBM are collaborating on the Condition Monitoring and Predictive Maintenance Testbed. The goal of the collaboration is to deliver interoperability among operational technology and informational technology as organizations search for better methods to manage and extend the life of aging assets in heavy machinery, power generation, process manufacturing and a variety of other industrial sectors.

In a new age of Big Analog Data solutions, users can take advantage of machine learning to harness value from information. They can collect raw data and derive insights to improve operations, equipment and processes. Users can also realize huge cost savings and competitive advantages as artificial intelligence-driven prognostics warn of component failures before they occur, identify suboptimal operating conditions and assist with root-cause analysis.

NI’s open, software-centric platform creates the foundation of the Condition Monitoring and Predictive Maintenance Testbed, which delivers on the opportunities present in machine learning. Customers can apply SparkCognition’s cognitive analytics to proactively avoid unplanned equipment fatigue and failure of critical assets; thus, enhancing system capabilities by gaining advanced insights into equipment health and remediation solutions. These capabilities help increase operational efficiencies and safety, and decrease maintenance costs.

“With IIoT technologies driving vast sensorization of industrial equipment, and massive amounts of data being collected on those assets, the collaboration between NI and SparkCognition powers the complex and intelligent processing of information to produce valuable insights,” said Stuart Gillen, director of business development at SparkCognition.

“We are excited that our platform can acquire the data and extract the features to drive SparkCognition analytics for IIoT solutions,” said Jamie Smith, director of embedded systems at NI. “Combined with existing technologies in the testbed, the addition of SparkCognition presents new ways to help automate the process of turning sensor data into business insight.”

With this software-defined approach, viewing, managing and refining a broad range of assets stands in direct contrast to the traditional, fixed-functionality methods of the past, which often take too much time, rely on hard-to-find talent and require custom model building for each type of asset.