by Gary Mintchell | Jan 22, 2016 | Automation, Education, Internet of Things, Networking, News, Operations Management

What was once called Information Technology (IT) and then Manufacturing IT (for the IT jobs directly working with the plant such as MES applications) now seems to be falling under the Internet of Things label. Probably part of the reason that there is confusion as to what the IoT term really means.

What was once called Information Technology (IT) and then Manufacturing IT (for the IT jobs directly working with the plant such as MES applications) now seems to be falling under the Internet of Things label. Probably part of the reason that there is confusion as to what the IoT term really means.

Terminology aside, Rockwell Automation and the Industrial IP Advantage (industrial-ip.org) group it has formed have been investing much in providing training on a variety of networking and IT topics. In today’s news, Rockwell Automation and Sunset Learning Institute (SLI) are teaming up to improve and increase access to continuing education and certifications surrounding the Industrial Internet of Things (IoT).

Rockwell Automation has rolled out several courses and a certification program over the last year with its Strategic Alliance Partner Cisco. New courses and certifications can help both IT and OT workers gain the skills needed to manage, administer, design and operate converged industrial networks–now becoming known as industrial internet of things networks. These include the Managing Industrial Networks with Cisco Networking Technologies (IMINS) training course; Managing Industrial Networks for Manufacturing with Cisco Technologies (IMINS2); and CCNA Industrial certification.

SLI specializes in delivering and developing authorized Cisco training. SLI has been a top-tier Authorized Cisco Learning Partner for 20 years. The courses and certifications supported by Rockwell Automation-SLI collaboration include:

- Interconnecting Cisco Networking Devices Part 1 (ICND1): A five-day course on how to install, operate, configure and verify basic IPv4 and IPv6 networks.

- Interconnecting Cisco Networking Devices Part 2 (ICND2): A five-day course on how to install, configure, operate and troubleshoot a small enterprise network.

- Interconnecting Cisco Networking Devices Accelerated (CCNAX): An advanced, five-day course consisting of ICND1 and ICND2 content in its entirety.

- Implementing Cisco Unified Wireless Networking Essentials: A five-day course designed to prepare for the CCNA wireless certification, an associate-level certification specializing in the wireless field.

Students can register for courses via the Rockwell Automation and SLI websites.

Take Advantage of Industrial Internet of Things Opportunities

“Our customers are tasked with building and managing networks and information systems that are different from anything their predecessors confronted,” said Glenn Goldney, global business manager for training services, Rockwell Automation. “Pairing SLI’s qualifications with our own expertise in OT provides IT and OT professionals with premium quality IoT training. These are the skills workers need to take advantage of IoT to drive new opportunities, and unite traditionally disparate practices.”

“The convergence of IT and OT makes it critical that we partner with the very best in the OT space,” said Rick Morgan, CEO, Sunset Learning Institute. “Combining our in-depth knowledge of IT and Cisco markets with Rockwell Automation expertise in the OT space creates an unrivaled partnership in the emerging IoT marketplace.”

SLI also provides a distinct training delivery platform with its High-Definition, Instructor-Led Training (HD-ILT) Network. HD-ILT is SLI’s proprietary video conferencing and patented, remote-lab training modality. Students using HD-ILT have interactive training sessions with two-way, high-definition video and real-time audio, giving instructors and students easy and full visibility of one another.

With over 50 locations across the U.S., Canada and Latin America, the SLI HD-ILT network significantly increases options for IT and OT professionals looking for training without the travel costs. Training is also available in person at Rockwell Automation and SLI facilities across North America. Rockwell Automation and SLI expect to add joint course offerings in the years ahead. All courses are open for registration.

by Gary Mintchell | Jan 21, 2016 | Automation, Operator Interface, Technology

Apps are so last year. Now the topic of the future appears to be bots and conversational interfaces (Siri, etc.). Many automation and control suppliers have added apps for smart phones. I have a bunch loaded on my iPhone. How many do you have? Do you use them? What if there were another interface?

I’ve run across two articles lately that deal with a coming new interface. Check them out and let me know what you think about these in the context of the next HMI/automation/control/MES generations.

Sam Lessin wrote a good overview at The Information (that is a subscription Website, but as a subscriber I can unlock some articles) “On Bots, Conversational Apps, and Fin.”

Lessin looks at the history of personal computing from shrink wrapped applications to the Web to apps to bots. Another way to look at it is client side to server side to client side and now back to server side. Server side is easier for developers and removes some power from vertical companies.

Lessen also notes a certain “app fatigue” where we have loaded up on apps on our phones only to discover we use only a fraction of them.

I spotted this on Medium–a new “blogging” platform for non-serious bloggers.

It was written by Ryan Block–former editor-in-chief of Engadget, founder of gdgt (both of which sold to AOL), and now a serial entrepreneur.

He looks at human/computer interfaces, “People who’ve been around technology a while have a tendency to think of human-computer interfaces as phases in some kind of a Jobsian linear evolution, starting with encoded punch cards, evolving into command lines, then graphical interfaces, and eventually touch.”

Continuing, “Well, the first step is to stop thinking of human computer interaction as a linear progression. A better metaphor might be to think of interfaces as existing on a scale, ranging from visible to invisible.”

Examples of visible interfaces would include the punchcard, many command line interfaces, and quite a bit of very useful, but ultimately shoddy, pieces of software.

Completely invisible interfaces, on the other hand, would be characterized by frictionless, low cognitive load usage with little to no (apparent) training necessary. Invisibility doesn’t necessarily mean that you can’t physically see the interface (although some invisible interfaces may actually be invisible); instead, think of it as a measure of how fast and how much you can forget that the tool is there at all, even while you’re using it.

Examples of interfaces that approach invisibility include many forms of messaging, the Amazon Echo, the proximity-sensing / auto-locking doors on the Tesla Model S, and especially the ship computer in Star Trek (the voice interface, that is — not the LCARS GUI, which highly visible interface. Ahem!).

Conversation-driven product design is still nascent, but messaging-driven products are still represent massive growth and opportunity, expected to grow by another another billion users in the next two years alone.

For the next generation, Snapchat is the interface for communicating with friends visually, iMessage and Messenger is the interface for communicating with friends textually, and Slack is (or soon will be) the interface for communicating with colleagues about work. And that’s to say nothing of the nearly two billion users currently on WhatsApp, WeChat, and Line.

As we move to increasingly invisible interfaces, I believe we’ll see a new class of messaging-centric platforms emerge alongside existing platforms in mobile, cloud, etc.

As with every platform and interface paradigm, messaging has its own unique set of capabilities, limitations, and opportunities. That’s where bots come in. In the context of a conversation, bots are the primary mode for manifesting a machine interface.

Organizations will soon discover — yet again — that teams want to work the way they live, and we all live in messaging. Workflows will be retooled from the bottom-up to optimize around real-time, channel based, searchable, conversational interfaces.

Humans will always be the entities we desire talking to and collaborating with. But in the not too distant future, bots will be how things actually get done.

by Gary Mintchell | Jan 20, 2016 | Automation, Internet of Things, Networking, Operations Management

Everyone is in a rush to get an opinion or observation published about the Internet of Things. Evidently it gets lots of page views. Recently other analysts have been publishing thought pieces on IoT in Industry. It appears they have reached the same conclusion that I first broached a couple of years ago. The IoT is not a “thing.” To make any sense of it and use it for any strategy, it must be thought of as an ecosystem encompassing a variety of technologies.

Everyone is in a rush to get an opinion or observation published about the Internet of Things. Evidently it gets lots of page views. Recently other analysts have been publishing thought pieces on IoT in Industry. It appears they have reached the same conclusion that I first broached a couple of years ago. The IoT is not a “thing.” To make any sense of it and use it for any strategy, it must be thought of as an ecosystem encompassing a variety of technologies.

Here is an article that appeared in the Sloan MIT Management Review. Since I am a subscriber, I don’t know if you can see the article at this link.

The writer is Sam Ransbotham is an associate professor of information systems at the Carroll School of Management at Boston College and the MIT Sloan Management Review Guest Editor for the Data and Analytics Big Idea Initiative. He suggests, “The Internet of Things will bring huge changes to the way markets and businesses work — and it could get messy.”

Here is a bromide that I’ve read a thousand times, “Most businesses aren’t ready for the changes to the marketplace that the Internet of Things will bring. But the time to prepare for them is now.”

Actually most business adapt. Some are visionary and will develop new products, processes, and services–and make a lot of money. Others will adapt and survive. Still others will wonder what happened and die. That is the way of business for at least 5,000 years.

Use Case for Internet of Things

“Yes, the potential insights from IoT are enticing. For example, it’s fun to think about the potential personal and even societal benefits from self-driving cars, such as fewer accidents, no problems with parking, more productivity while traveling, car sharing, greater infrastructure efficiency, etc. But perhaps a more profound implication is the data that they can collect. These cars will also be widely distributed “things,” gathering performance data that can help manufacturers diagnose problems, operational data that can help mechanics prevent failures, driver data that can help insurers understand risk, road data that can help cities improve infrastructure, etc. These kinds of insights, we’re ready for.”

But there are a lot more changes coming with the IoT transformation than many people may recognize.

Ransbothem looks into information technology as a model for what will happen in IoT. “About a decade ago, advances in information technology converged to fuel a boom in corporate use of analytics. First, widespread implementation of information systems captured unprecedented amount of data in ways that could be used in isolation or combined. Second, tools and technologies allowed the inexpensive storage and processing. Third, savvy analytical innovators creatively combined these to show everyone else what could be done.”

We have seen all this play out in industrial systems. There remains more to be done, here, though.

He proceeds to look at Internet of Things. “First, the cost and physical size of sensor technology have dropped such that they can be incorporated into most items. Second, widespread communications infrastructure is in place to allow these distributed components to coordinate. Third, once again, savvy innovators are showing the rest of us the possibilities from the data they collect.”

Manufacturing and production are not only poised to exploit these technologies and strategies, they have already been implementing to one degree or another. But his point is valid. IoT needs the ecosystem of sensing devices, networking, communication technology, databases, analytics, and visualization.

Ransbothem identifies four areas of change. Of these, I direct your attention to the last–process changes. I think everything feeds into process changes–not just the processes to make things, but also the information technology, supply chain, and human processes that must not only adapt but thrive with the new information awareness.

- Market Power: IoT should provide a greater amount and a greater value of data, but are companies ready to align their interests in obtaining value from this data with the multiple other companies and end users who create, own, and service the products that originate the data? In the driverless car example, it is easy to see how multiple stakeholders could make use of the data from cars; the same is true for other devices. But it may not be clear who owns what data and how it can be used.

- Complexity: Few organizations are prepared to be hardware and software development companies. But that’s what the Internet of Things will enable. As products are built with embedded sensors, the component mix increases in complexity. As a result, manufacturing systems and supply chains will become more elaborate. Software embedded in products will need to be updateable when the inevitable shortcomings are found.

- Security: If we believe data is valuable, then we need to be ready for people to want to take it from us — why would data be any different than any other precious item? The IoT context intensifies the need for security requirements; for example, sensors or software that allow physical control of the product make attacks easier.

- Process Changes: Many business processes continue to be “pull” oriented. Information is gathered, then analyzed, then decisions are made. This works when change is slow. But with the IoT transition, data will stream in constantly, defying routine reporting and normal working hours. Flooding data from IoT devices will give opportunities for quick reaction, but only if organizations can develop the capacity needed to take advantage of it. Few mainstream large companies are ready for this, much less small- to medium-sized companies that lack the resources of their larger corporate brethren.

The Internet of Things is bringing and will continue to bring advances in how we do business. How well will executives, managers, and engineers execute on this vision? That is key.

by Gary Mintchell | Jan 19, 2016 | Leadership, Podcast

Leadership and sports. OK, I maybe overdosing on NFL games. I have taken some sports analogies and applied to pondered the topic in general.

Leadership on YouTube–channel moved

Note: This podcast is also on YouTube. If you previously subscribed to my YouTube videos, Google decided at some point to move me to a different channel. You can go there and subscribe to see me in living color.

What got me thinking about this was how some key players in team sports seem to think they are one-person teams. Good leaders have strategies for involving people.

by Gary Mintchell | Jan 18, 2016 | Asset Performance Management, Automation, Internet of Things, Manufacturing IT, Networking, Operations Management, Technology

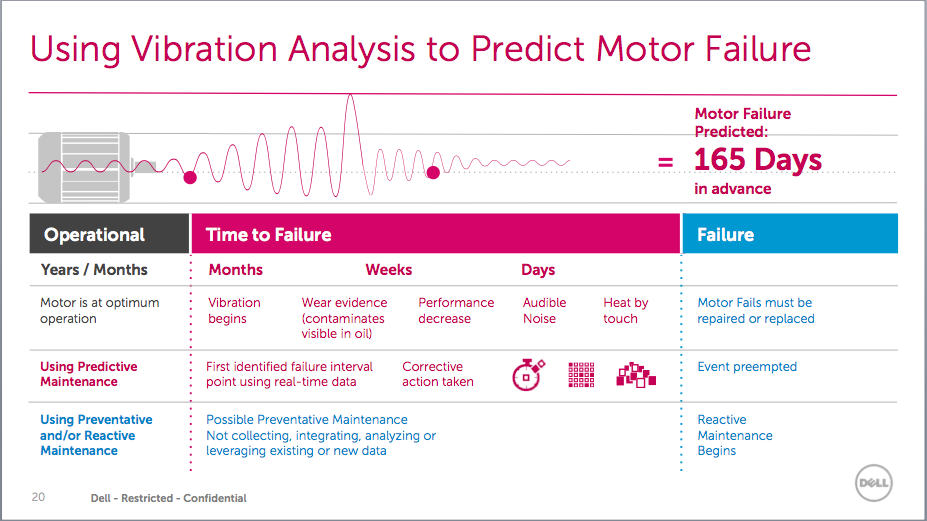

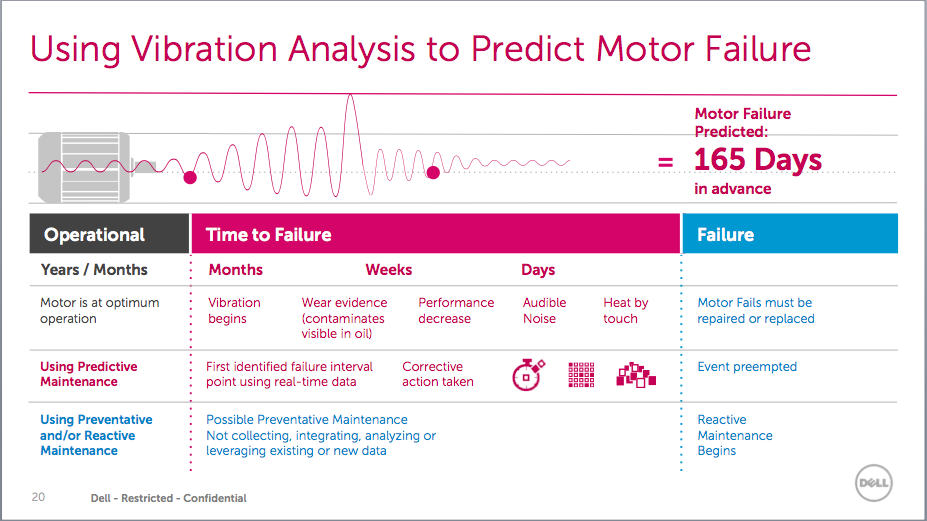

Predictive maintenance benefits more from implementation of the Internet of Things than perhaps any other function at this early stage of wide-spread adoption.

Predictive maintenance benefits more from implementation of the Internet of Things than perhaps any other function at this early stage of wide-spread adoption.

I have written on this topic several times over the past couple of years.

Predictive Condition-Based Maintenance

IoT Testbed For Condition Monitoring To Predictive Maintenance

Use Of Internet of Things Enhances Preventive Maintenance

10 Myths About Predictive Analytics (SAP)

A foulup at Starbucks, Preventive Maintenance Prevents Production

Cloud Platforms For Internet of Things

Predictive or Condition-Based

The asset management community has not made it easy for us generalists with its terminology and definitions. Searching for predictive maintenance (PdM) often serves up results for condition-based maintenance. I am not going to attempt a final definition, but I found something that made sense on the OSIsoft Website. “PdM defines methods to predict or diagnose problems in a piece of equipment based on trending of test results. These methods use non-intrusive testing techniques to measure and compute equipment performance trends.”

Condition-based maintenance (CBM) is a methodology that combines predictive and preventive maintenance with real-time monitoring. PdM uses CBM systems to detect fault sources well in advance of failure, making maintenance a proactive process. CBM accurately detects the current state of mechanical systems and predicts the systems’ ability to perform without failure.

Business Risk

The Aberdeen Group, Report: Building the Business Case for the Executive, December 2013, found that 40 percent of 149 manufacturing executives identified failure of critical assets as the top risk they face.

How do we mitigate this risk? Predictive maintenance and condition-based maintenance are methodologies that help. One thing that makes these strategies work is data. With sufficient data along with a model of the asset’s condition at operational efficiency, reliability engineers can begin to predict failures before they happen.

Just like your car, productive assets pick the worst time to fail. This unplanned downtime is exceedingly expensive. Using predictive technologies, managers can plan for shutdowns at an appropriate time. The right parts can be on hand, labor lined up, production schedules adjusted, all because everything can be planned.

I’ve been talking with Dell often since October when I attended Dell World and it unveiled its Internet of Things initiative.

The interesting thing about Dell compared to almost everyone else I cover is that they approach the IT/OT convergence issue from the IT side rather than the OT side.

Dell’s first IoT product is something I think we’ll see more of–analytics at the edge combined with gateway technology that can bring disparate sources of data together, massage them, send them off to the cloud for further analytics, storage, and visualization. Dell’s current partners are SAP for predictive maintenance and Statistica for analytics.

Expect to see more of these partnerships evolve. In some cases, such as PTC, we are seeing acquisitions to add IoT capability. On the other hand, larger companies who do not have enough in common overall to merge will forge partnerships to offer complete solutions to customers.

We see some of this through the rise of Industrial Internet and IP organizations.

Collecting, moving, analyzing, and displaying data is becoming a big and important business. Customer executives will come to appreciate the work as their companies gain efficiency–and profits.

What was once called Information Technology (IT) and then Manufacturing IT (for the IT jobs directly working with the plant such as MES applications) now seems to be falling under the Internet of Things label. Probably part of the reason that there is confusion as to what the IoT term really means.

What was once called Information Technology (IT) and then Manufacturing IT (for the IT jobs directly working with the plant such as MES applications) now seems to be falling under the Internet of Things label. Probably part of the reason that there is confusion as to what the IoT term really means.

Predictive maintenance benefits more from implementation of the Internet of Things than perhaps any other function at this early stage of wide-spread adoption.

Predictive maintenance benefits more from implementation of the Internet of Things than perhaps any other function at this early stage of wide-spread adoption.