by Gary Mintchell | Aug 29, 2018 | Internet of Things, Standards

Industrial Networking Enabling IIoT Communication white paper

Working consortia of companies and individuals researching a technology provide great guidance for users of the technology—usually in the form of white papers. The Industrial Internet Consortium (IIC) has been especially prolific lately. This means many companies and individuals see the importance of donating time and expertise to the cause.

The IIC has announced the IIC Industrial Networking Enabling IIoT Communication white paper. The paper serves as an introductory guide on industrial networking for IIoT system designers and network engineers, and offers practical solutions based on key usage scenarios.

“Industrial networking is the foundation of IIoT,” said David Zhe Lou, Chief Researcher, Huawei Technologies. “There are many choices of networking technologies depending on the application, the industrial network, deployment situation and conditions, but there is no universal or preferred industrial networking solution.”

Industrial networking infrastructure and technologies reside at the IP layer and below, and enable industrial assets, such as machines, sites and environments, to connect to the business professionals supporting applications across a wide range of industry sectors. Industrial networking technologies provide the foundation for applications that enable manufacturing productivity and profitability.

“IIoT applications have different needs depending on the industrial application and therefore demand robust, flexible and secure networks,” said Cliff Whitehead, Business Development Manager, Rockwell Automation. “This white paper will help IIoT system designers and network engineers understand the tradeoffs they can consider when designing an industrial network architecture that will be a strong foundation for current and future IIoT scenarios.”

Industrial networking is different from networking for the enterprise or networking for consumers. For example, IIoT system designers and network engineers need to make decisions about using wired or wireless communications. They have to figure out how to support mobility applications such as vehicles, equipment, robots and workers. They must also consider the lifecycle of deployments, physical conditions, such as those found in mining and agriculture, and technical requirements, which can vary from relaxed to highly demanding.

“Networking technologies range from industry-specific to universal, such as the emerging 5G, which meets diverse industrial needs,” continued Jan Höller, Research Fellow at Ericsson. “Industrial developers need guidance when devising solutions to select the right networking technologies, and this white paper is the first step to providing the missing methods and tools.”

The Industrial Networking Enabling IIoT Communication white paper sets the stage for the Industrial Internet Network Framework (IINF), which will complement the Industrial Internet Connectivity Framework (IICF) by detailing requirements and best available technologies for the lower three layers of the industrial internet communication stack.

The full IIC Industrial Networking Enabling IIoT Communication white paper and a list of IIC members who contributed can be found on the IIC website:

The Industrial Internet Consortium is a program of the Object Management Group (OMG).

by Gary Mintchell | Jun 4, 2018 | Standards, Technology

Microsoft acquiring GitHub, the repository of many open source projects, on the surface appears almost as an oxymoron. However, as I’ve written previously about big companies and OPC UA standard big companies now find open source and interoperability to be sound business decisions rather than threatening to their proprietary hold on technology.

OPC and Standards

Two years ago in my Podcast Gary on Manufacturing 149 also found on YouTube, I asked the question why major suppliers of automation technology for manufacturing/production hated OPC UA—an industry information model standard. That is by far the most viewed YouTube podcast I’ve ever done. I followed up with Gary on Manufacturing 175 and YouTube to update the situation to current situation.

It is still getting comments, some two years later. Some guy (probably works for a big company?) even dissed me about it.

However, the industry witnessed an almost tectonic shift in the approach of these automation suppliers toward standards. First Siemens went all in on OPC UA. Then last November and following Rockwell Automation has had several deep discussions with me about the adoption of OPC UA.

Why? Users demand more interoperability. And using standards is the easiest way forward for interoperability. Suppliers have discovered that standards allow them to continue to push development of their “black boxes” of technology while allowing themselves and their customers to assemble systems of technology.

Microsoft News

In my favorite news site, Axios, Ina Fried writes:

Microsoft announced this morning it is acquiring GitHub, the social network for coders as well as home to millions of different software projects, for $7.5 billion.

“The era of the intelligent cloud and intelligent edge is upon us. Computing is becoming embedded in the world, with every part of our daily life and work and every aspect of our society and economy being transformed by digital technology. Developers are the builders of this new era, writing the world’s code. And GitHub is their home.”

— Satya Nadellla, CEO, Microsoft

Why it matters: This would further highlight the complete turnaround the company has already made in its stance toward source software.

Behind the scenes: While former Microsoft CEO Steve Ballmer once called Linux a cancer, the company has steadily warmed to open source, with Nadella embracing it with open arms.

GitHub plays into that strategy as it’s used by developers of all stripes to store their code projects. The San Francisco-based company was founded in 2008 and is now home to 80 million software repositories. The company has been searching for a new CEO since last year.

Why it matters: Playing host to the world’s code doesn’t necessarily make Microsoft a more central player, but it could tightly integrate GitHub into its developer tools. Microsoft decided last year to shut down its own CodePlex software repository, bowing to GitHub’s popularity.

What about Windows? Though certainly a fan of its homegrown operating system, Microsoft’s main goal these days is to be in tight with developers and get them writing code that can live in its Azure cloud.

Microsoft even dropped the Windows name from Azure, reflecting the fact you don’t have to use Windows to work with Azure.

History lesson: Microsoft’s shift to embrace Linux is somewhat reminiscent of the earlier move IBM made to do so. Both companies are now seen as the mature veterans of the enterprise market, more interested in meeting corporate computing needs than pushing homegrown architectures.

This information was also posted on the Microsoft Blog.

Other Open Source Information

My other travels and interviews have yielded other companies who have invested heavily in open source.

Within the last two years I have had a few conversations with Microsoft about their open source code donations. While I am a little surprised at acquiring GitHub, perhaps this will lend financial stability to the platform (although we do have to note that large company investments do not always insure financial stability.

Dell Technologies and Hewlett Packard Enterprise, two companies I have more recently studied are both proud to be contributors to open source. A couple of years ago considerable time at one of the keynotes at Dell World to open source projects.

I think that some of these companies are realizing that they don’t have to invent everything themselves. Being good software citizens benefits them as well as the community.

by Gary Mintchell | May 14, 2018 | Automation, Networking, News, Standards

Hannover Messe continues to reflect the trend of companies joining alliances to develop and promote standards and interoperability. While I did not have an interview with the Avnu Alliance while I was in Hannover, I talked with some members and obtained other information. Avnu Alliance promotes adoption of the Time Sensitive Networking (TSN) extension to Ethernet.

Specifically, Avnu Alliance is a community creating an interoperable ecosystem of low-latency, time-synchronized, highly reliable networked devices using open standards. Avnu creates comprehensive certification programs to ensure interoperability of networked devices. The foundational technology enables deterministic synchronized networking based on IEEE Audio Video Bridging (AVB) / Time Sensitive Networking (TSN) base standards. The Alliance, in conjunction with other complimentary standards bodies and alliances, provides a united network foundation for use in professional AV, automotive, industrial control and consumer segments.

The adoption pace of TSN from 2017 to 2018 was amazing.

I always drop by the Industrial Internet Consortium (IIC) area at Hannover and check out the TSN Testbed for Flexible Manufacturing. The testbed was developed with two major goals – to show TSN’s readiness to accelerate the marketplace; and to show the business value of TSN in converged, deterministic IIoT networks. Momentum is increasing for the testbed, with the IIC hosting its 10th plugfest in an 18-month timeframe at the Bosch Rexroth facility in Frankfurt, Germany and its 9th plugfest, which was held in Austin, TX in February at National Instruments (NI) headquarters following a joint workshop on interoperability with Avnu Alliance. The TSN Testbed recently integrated test tools from Avnu Alliance members, Calnex, Ixia and Spirent into plugfest activities, and demonstrated interoperability of TSN devices from more than 25 companies performing real-time automation and control automation functions over TSN.

Any Avnu Alliance member is welcome to join the IIC TSN Testbed or to participate in a plugfest. Upcoming plugfests will be held in Austin, TX from June 26-29, 2018 and in Stuttgart from July 24-27, 2018.

The Edge Computing Consortium (ECC) along with members and Avnu Alliance, hosted a press conference to announce new developments surrounding the newly created OPC UA TSN testbed. The testbed demonstrates six major IIoT scenarios mimicking processes found in smart manufacturing settings and utilizing products across different TSN vendors. Avnu Alliance is a key partner supporting the development of the testbed with the ECC in the shared goal of enabling manufacturers to test their products for interoperability and conduct trials of real-world systems as an early check for problems.

Tom Weingartner, Avnu Alliance member and Analog Devices’ marketing director for Deterministic Ethernet Technology Group, represented the Alliance at an announcement ceremony.

Paul Didier, Avnu Alliance member and IoT solutions architect, Cisco delivered a talk at the Industrie 4.0 meet the Industrial Internet Forum, in a presentation titled “Time Sensitive Networks – Where does the technology stand and what to expect”. He will provide an update on TSN and how manufacturers, alliances and liaison groups are working together to advance the technology and its implementation in the IIoT.

Paul will present an additional lecture for the Forum on “Modernizing Your Industrial Manufacturing Network”. The presentation will follow the findings coming out of the IIC TSN Testbed and its capabilities, including information on how manufacturing automation and control infrastructure vendors and key decision-makers can leverage TSN for a variety of operational benefits, including increased connectivity between devices and the ability to extract and analyze valuable information through interconnectivity.

“HANNOVER continues to be a key industry event for both Avnu Alliance members and liaison groups that we work with to educate and increase awareness of TSN as a solution for the growing IIoT,” said Todd Walter, Avnu Alliance Industrial Segment Leader and Chief Marketing Manager at NI. “Whether through the developments coming from the TSN testbeds, speaking engagements or product demonstrations, our members and partners are committed to creating an interoperable TSN network that gives all industrial devices a more streamlined path to participating in the TSN ecosystem.

by Gary Mintchell | Mar 29, 2018 | Interoperability, Manufacturing IT, Standards

“Digital Transformation is so last year. While many legacy companies around the world are still grappling with “transforming” their digital ecosystems, the true leaders are already on to next hot topic: Digital Transformation 2.0. We’ll call it ‘Digital Reinvention.’ ” Media relations agencies, aka PR agencies, must be under constant pressure to get messages published however they can. I’m flooded with teasers such as this one. And few, if any, take the time to know if their target is a good place for the news. It’s almost like there is no strategy other than send out as many promos as possible and hope some land.

Most I just delete. Then I get the inevitable follow up, when are you going to run my news (that probably doesn’t apply to your coverage but I need numbers)?

I bit on this one. Is Digital Reinvention an attempt to coin a new marketing phrase? Is it a real thing with a real definition? Dr. Google told me that the phrase has been around for several years, but it has not caught on. Maybe Rick Bullotta will catch on with Industry 4.5? (Search on LinkedIn)

The press release introduced me to Alfresco co-founder John Newton. He was quoted, “the whole notion of infinite computing, infinite storage, and resilience is just completely different.” Those changes are having a profound impact on how companies think about their future. Cloud adoption is happening at the speed of light as companies embrace the idea that they are no longer limited by server space. Responsive design and responsive applications are driving not just apps, but the entire business model. Companies like Uber, Airbnb, TaskRabbit and the behemoth, Amazon, are taking those words to heart and constantly reinventing each day.

So, I talked with Newton. He mentioned they had done a survey on what companies were achieving with Digital Transformation, how fast they were growing—innovative, size, etc. That formed the foundation for his thoughts. He told me to look at platform, design, and business operations. How open are they to connecting to customers and suppliers. Innovators looked at Digital Transformation not as technology only but also as business operations stretching to customers and supply chain.

Newton called out ‘design thinking’ that looks from the users point of view to make technology human. Another type of today’s thinking is ‘open’—open source, open standards, open architecture. “This will trump all other forms. It is naturally attractive to customers. The more profound is platform thinking. This is dominating in the stock market. Five of the top 10 value companies are platform plays, including Google, Apple, Facebook, Amazon. They have a long term relationship with customers. In manufacturing think after-service care, maintenance and service relationships. Product is almost a loss leader. Digital twin is part of the platform play, for example, using it to predict failures.

Twenty-five minutes into the conversation, Newton had not tried to sell me on Alfresco. I had looked him up and noted he had founded Documentuum before founding Alfresco. So, I had to ask. Always need to learn about new companies. “We help create and manage documents and processes,” he told me. “We have a different way of thinking—open, open source, architecture, cloud friendly, AWS templates, manage in a matter of minutes.” Sounds interesting. All of my favorite concepts.

by Gary Mintchell | Jan 31, 2018 | Automation, Networking, Standards, Technology

Time Sensitive Networking (TSN) defines the future of networking. Most of the specifications have been agreed upon by the IEEE 802 committee, only a few remain to be completed. I have written a White Paper describing OPC UA over TSN for information communication. This corroborates the idea that information is where the new momentum lies within manufacturing and production technologies.

One topic of concern to many regards whether or not TSN will supplant current fieldbus technologies. Indeed, on the surface it appears that TSN can perform most, if not all, of those functions.

Therefore, it behooves the fieldbus groups to figure out how to work with this new technology in order to add value for users.

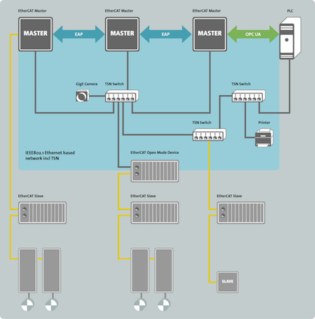

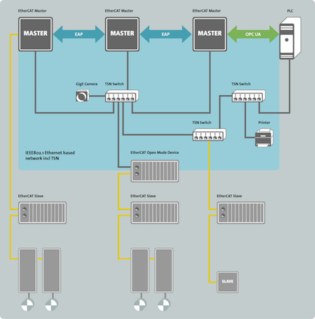

The EtherCAT Technology Group (ETG) has taken the initiative and supplemented EtherCAT with Time Sensitive Networking (TSN) technologies, expanding the field of possible EtherCAT applications to include heterogeneous network environments. With the help of TSN, industrial controls can contact a number of different EtherCAT segments in real-time through Ethernet networks.

In doing so, no changes to the EtherCAT slave devices are required: the EtherCAT Device Protocol, including all high performance characteristics, is fully preserved. Also expanded by TSN is the EtherCAT Automation Protocol (EAP) for communication between controls, which will result in even more deterministic performance on this level.

The ETG has specified the technology expansion in the form of a profile, which highlights the fact that no changes to the TSN standards are needed. This approach also considerably simplifies the adaptation to the final versions of the TSN technologies, because specification in the IEEE is not yet fully complete.

The ETG has supported the development of TSN from the very beginning through active participation in the IEEE committee, and is coordinating the specifications through a liaison with the IEEE 802.1 Working Group. This ensures that the ETG will also be able to access the IEEE 802.1 specifications that have not yet been adopted. Therefore, the technology can be introduced almost at the same time as TSN.

EtherCAT uses the TSN streams with any data rates for real-time communication above EtherCAT device segments. In the segment itself nothing is changed – the unique performance of the EtherCAT protocol built upon processing on the fly, highly precise synchronization, flexible topology selection, excellent diagnostic capabilities and simplicity through fully automated addressing of devices are all fully preserved. Similarly, the thousands of different EtherCAT devices available worldwide do not need to be modified at all. The stream adaptation feature that connects the EtherCAT segment to the heterogeneous TSN network can be placed either in the last TSN switch or in the first EtherCAT slave device.

Dr. Guido Beckmann, Chairman of the ETG Technical Committee classifies the new specification as such: “The incorporation of TSN standards will significantly improve the real-time characteristics of generic Ethernet. With our technology expansion we make use of TSN in an ideal way, and exactly where TSN can offer significant advantages – in the factory networks. As one frame is sufficient for EtherCAT to communicate with a whole segment, and thus with the entire fieldbus network, EtherCAT is virtually predestined for integration with TSN networks. We achieve this without turning our technology inside out. EtherCAT together with TSN offers the ‘best of both worlds’. Therefore, this prepares EtherCAT for the future perfectly.”

by Gary Mintchell | Nov 13, 2017 | Industrial Computers, Internet of Things, Standards

IoT Platforms are all the rage. All God’s children need a platform, it seems. Most larger companies have a platform. Oh, and all promise it’s “open” to everyone’s connections. Then there is open source—check out Dell, the Linux Foundation, and others who have developed the EdgeX Foundry.

Now we have an Asian developed one—mostly Japanese along with Taiwan-based Advantech—called the Edgecross Consortium. Edgecross evidently refers to a focus on edge computing and cross vendor.

I received the first notice from Advantech who announced it has partnered with Mitsubishi Electric, Omron, NEC, IBM Japan, and Oracle Japan to establish the “Edgecross Consortium” to overcome boundaries between companies and industries in order to realize collaboration between factory automation and IT. The objective is to create new value centered on edge computing.

The Consortium news release states, “In this way, it will contribute to the promotion of IoT, for which demand is increasing on a global scale, as well as Society 5.0, proposed by the Japanese government, and activities of Connected Industries, which tie in to Society 5.0.”

Initial activities of the Consortium will begin with the development of specifications for the Edgecross open software platform and promoting its dissemination for edge computing from Japan to harmonize with FA and IT. This initial work will include providing avenues for supporting companies to cooperate and collaborate beyond the framework of companies and industries. The Consortium will aim to expand applications for various industries in addition to initiating activities in the global arena in the future.

I should note here that in America and Europe, we generally refer to bringing OT and IT together (rather than FA).

The date of founding is scheduled for November 29, 2017, and an exhibition is planned at the System Control Fair 2017, to be held on the same day.

Overview of Edgecross

An open software platform of edge computing area from Japan built by consortium members beyond the boundaries of companies and industries to realize collaboration with FA and IT.

Features

Real-time diagnosis and feedback

Realizing real-time feedback to the production site by analyzing and diagnosing the data at location close to the production sites

Creating models from production sites

Data can be easily utilized by people or by applications by layering and abstracting the Big data of the production sites

Utilization of various applications in the edge computing area

IT applications can be easily applied to FA application

Applications may be selected from an extensive lineup depending on the situation

System construction completed in the edge computing area are available

Collecting all types of data at the production site

Enable data collection from all equipment and devices regardless of vendor or network

Smooth coordination with FA and IT systems

Realizing supply chain and engineering chain optimization by seamless data coordination with IT systems including the cloud

Operates on industrial PCs

Mountable on various manufacturer’s industrial PCs (IPCs)

Here are a couple of executive quotes about the news.

“Partnering with leading global companies in accelerating our global business in Industry 4.0 is Advantech’s key strategy,” stated Allan Yang, CTO of Advantech. “Advantech joined the Mitsubishi e-F@ctory Alliance this April to foster business opportunities for smart manufacturing in Asia through co-marketing and co-exhibition. Joining the Edgecross Consortium is our next big step to expand global collaboration and business in Industry 4.0. We are very proud to be a part of Edgecross Consortium with these leading global companies; we are looking forward to collaborating with consortium members to develop Industry 4.0 products and solutions to enhance our customer experience.”

Yoshikazu Miyata, Executive Officer and Group President of Factory Automation Systems at Mitsubishi Electric, gave the following statement regarding the new partnership, “The consortium welcomes Advantech as a key member. We are happy to work with Advantech, a worldwide leading innovator for Edge computing and IoT solutions. We are looking forward to co-creating with Advantech to provide innovative IoT solutions to customers.”