by Gary Mintchell | Dec 7, 2016 | Commentary, News

Here is a bold manufacturing revival proposal from someone who has been deep in strategy. I worked with John A. Bernaden in his roles with Rockwell Automation and the Smart Manufacturing Leadership Coalition. Now retired, he evidently has time on his hands to think. I saw his blog post go up before he sent me his press release.

[Disclaimer: Bernaden is retired and no longer works for either organization nor speaks for them.]

Not one to be bashful, Bernaden begins, “Wall Street’s short-sighted leadership of U.S. Manufacturing has created a crisis!”

“They reap; but they do not sow. They restructure to take billions; but they do not reinvest to make trillions. They destroy industries; but they do not build new ones,” said John A. Bernaden, co-founder and past vice chairman of the Smart Manufacturing Leadership Coalition, Inc., a Washington DC nonprofit group.

Past bipartisan 20th Century U.S. industrial policies and Congressional programs have been complacent in creating this crisis, he continued.

“We need new leadership to create and construct a new era of revolutionary, highly-automated, IT-driven, super-productive, 21st Century Smart Manufacturing with a long-term vision to make America’s manufacturing great again,” Bernaden said.

Other nations have long-term policies and long-range programs to more smartly support their manufacturers at home and abroad, he said pointing to a new “Policy Makers Guide to Smart Manufacturing” published last week by the Information Technology and Information Foundation (ITIF), a Washington DC think-tank. The report provides a comprehensive summary of the long-term Smart Manufacturing policies and long-range programs established by other governments around the world, most notably by China, Germany, Japan and Korea.

“As a leader who values building things, President-elect Trump will soon have an opportunity to smartly lead our nation’s Manufacturing, to renovate the world’s oldest factories, as well as to start a construction wave of smart new factories and plants in every State in America,” said Bernaden.

To achieve the President’s huge vision to make American manufacturing great again, Bernaden drafted a bold $2 trillion to $3 trillion U.S. Manufacturing Stimulus Package with almost no cost to taxpayers for Congress to consider that he released today.

Here is the gist of his proposal. Comments welcome, but I’d suggest making them on John’s site. I did graduate studies in political science, but I have little appetite for politics anymore. The refreshing thing about this proposal, however, is that I find even “conservative” business leaders going to Washington or their state capitals with their collective hands out wanting a gift. This proposal supposedly eschews that.

Between $2 trillion to $3 trillion from repatriated corporate wealth stranded overseas could catalyze a construction wave of between 2,000 to 3,000 new factories — highly-automated, super-productive smart plants, via a stimulus package developed by Bernaden, co-founder and past vice chairman of the Smart Manufacturing Leadership Coalition, Inc., a five-year-old Washington DC non-profit group. Disclaimer, Bernaden is no longer affiliated with either Rockwell or SMLC. This is his proposal all by himself.

Corporations that repatriate past overseas earnings and purchase 20-year USA Industrial Bonds will annually receive 1/20th of their investment totally tax-free, although at a zero interest rate. USA Industrial Bond funds will then become 20-year interest-free loans for States to use in stimulating the construction of new smart factories, mainly by midsize manufacturers.

To avoid federal or state governments picking “winners and losers” which has been a historic failing of past U.S. industrial policies, according to Bernaden, each state’s Governor will appoint 15-member commissions, chiefly consisting of manufacturing and business leaders, to make loan decisions.

State commissions will make loans that range from $500 million to $5 billion to construct smart factories, with typical costs averaging $1 billion each. If multinational corporations repatriate $2 trillion tax-free by investing in these USA Industrial Bonds, a state like Alabama’s share will be $34 billion to loan to business leaders who could construct about 34 smart manufacturing plants, according to Bernaden.

American midsize manufacturers, in a “Mittelstand” movement, are expected to construct most of these new factories because of this unprecedented access to billion-dollar-size, long-term interest-free loans. In Germany, the “Mittelstand” or midsize manufacturers, are renown as the engine of their economy. The Trump-size stimulus plan is also expected to create millions of new jobs needed to operate as well as supply, support and service these newly constructed 21st Century smart factories

[Gary talking again] I find the interesting thing about this proposal to be reference to a highly successful strategy from Germany. The US seems to venerate hugeness. In the common business mind small to medium businesses exist for the purpose of acquisition to make larger companies even larger. But this inevitably stifles innovation and competition. Things grow stagnant.

Unfortunately, I doubt that a politician exists that has a clue about the German Mittelstand. Further, none seem to have any clues about manufacturing or technology. We elect lawyers and career politicians who in many cases never worked a day in their lives building things. Prove me wrong, I dare you. [Please note: in this entire conversation I’ve not said anything about the opinion spectrum or political parties.]

Further unfortunately, I don’t find Mr. Trump to be a manufacturing guy. He negotiates deals, buys properties, builds hotels and other buildings. However, he claims true religion on helping the manufacturing guy. Here’s hoping this proposal gets a little visibility and at the least spurs some conversations around the country.

by Gary Mintchell | Sep 2, 2016 | Automation, News, Technology

Ms. Ajarin Pattanapanchai, Deputy Secretary General, of Thailand Board of Investment, talked with me last week about the state of industry and innovation in that country.

She told me that productivity in Thailand is quite high, citing Toyota assembly as an example where it produces a car every 55 seconds in Japan and a nearly equal 58 seconds in Thailand.

While the main topic was robotics, which I will discuss below, she also pointed out that Thailand has a large petrochemical complex—the 5th largest in the world—with the environment a considerable concern. So, the government agency partnered for a real-time monitoring of air direct to the agency.

Given Thailand’s dominance in ASEAN automotive markets, the country has seen an increase in investments from companies such as robotics giant Nachi and other firms providing technology and supply chain products to Thailand’s growing automotive markets. Growth of the robotics industry in Thailand is expected to increase, as the vehicle manufacturing industry in the Kingdom continues to expand in both commercial and private use motorcycles, trucks, and cars.

Robotic and Automation Machinery

Currently, there are more than 60 companies producing robotic and automation machinery in Thailand, such as Eureka Automation, CT Asia Robotic, Yutaka Robot Systems, Ryoei, and Robosis. These companies have developed and produced industrial robots that meet international standards and are gaining ground with the competition because of their high quality and competitive pricing.

Just last year, ABB opened a Robot Applications Center in Thailand and introduced “YuMi,” the world’s first truly collaborative dual-arm robot. Other companies who have located robotics operations in Thailand include:

- Globax Robot System (Thailand) – a Japanese company that produces Robotic Production Line;

- Kuka Robotics – a German company, a world leader in robotics systems, which has located a business operation in Thailand;

- Fillomatic Global Industries – an Indonesian company that produces robotic bottle filling machines and robotic bottle capping machines;

- Cal-comp Electronics –a Taiwanese company that produces robotic computers.

Thailand has the highest concentration of automotive companies in Asia and the 12th largest automotive production capacity in the world, directly providing vehicles for Indonesia, Vietnam, the Philippines, and other nearby and ASEAN countries. Automotive companies with production facilities in Thailand include: Ford, Isuzu, Mazda, Mitsubishi, BMW, General Motors, Daihatsu, Honda, Mercedes-Benz, Nissan, Tata, Toyota, and Volvo.

Thailand Imports

In 2016, Thai imports of industrial robotics and automation systems are estimated to top $47.3 million USD, and this number is expected to grow. The imported machinery has mostly been used for automotive, electrical appliances and electronics, and in the food processing industry.

Both automation and robotics have gained an important foothold in Thailand’s growth and development. Many universities in Thailand offer courses for students interested in this field, with the most specialized course being offered by the Institute of Field Robotics (FIBO) at King Mongkut’s University of Technology, Thonburi.

Many robots developed in-house by universities and private companies, in both the industrial and service categories, have also found use in real world applications. Mahidol University’s Bartlab Rescue Robot, Hive Ground’s Flare Stack Inspection Drone and Zeabus Autonomous Underwater vehicle (AUV), and CT Asia Robotics’s Dinsow Robot are some prominent examples. Given these advances, it is evident that Thai researchers and engineers possess the necessary skills and technical knowhow, and that Thailand is ready to be a hub for investment in these areas.

The country is a hub for automotive and electrical and electronics production in ASEAN. Thailand ranked 12th globally for motor vehicle production and 6th for commercial vehicle production in 2015. As for the electrical and electronics industry, Thailand has experienced a 7% growth in export value as measured from 2011, reaching an impressive figure of THB 435 billion (USD 12 billion) in 2015. The country is also renowned for being the second largest global producer and exporter of data storage units like Hard Disk Drives (HDD).

The BOI recognizes the importance of automation and robotics and they belong to the future industries promoted under the Super Cluster category. Examples of activities eligible for incentives in these industries include microelectronics design, embedded system design, and embedded software. Recently, the BOI approved additional activities to expedite investment projects in these future industries.

High value-added software development is one of those additional activities and it includes developing system software for advanced technology devices (including business process management) and developing industrial software used to support manufacturing. Investors can apply for general incentives that include an 8 year income tax exemption and import duty on machinery, and raw materials. However, they can apply for incentives under the Super Cluster policy if they meet certain specific criteria and not only get an 8 year income tax exemption, but also 50% Corporate Income Tax (CIT) reduction for 5 years. Non-tax incentives include the right to own land and work permits for expatriates.

by Gary Mintchell | Jan 6, 2015 | News

News has come in from the International CES show in Las Vegas (the show formerly known as the Consumer Electronics Show). It sounds more like a Detroit Auto Show than consumer electronics. Maybe the reason for the name change.

News has come in from the International CES show in Las Vegas (the show formerly known as the Consumer Electronics Show). It sounds more like a Detroit Auto Show than consumer electronics. Maybe the reason for the name change.

Toyota is opening the door to the hydrogen future for automobiles, making available thousands of hydrogen fuel cell patents royalty free. Announced at the 2015 International CES Show, this Toyota initiative is anticipated to spur development and introduction of innovative fuel cell technologies around the world.

Pollution reduction

Earl Nightingale developed the personal development industry back in the 50s and 60s. One of his recurring themes was the common sense of powering cars with hydrogen. Hydrogen is plentiful. The byproduct of “burning” it is non-toxic.

Well, Toyota has been working on hydrogen power and held a major press conference at CES.

[Aside: I’ve thought some about directions in trade press relative to how you might digest your news—especially how marketers want to capture that media to get their message out in a seemingly objective format. My first notice of this press conference was a notification on my old Tekzilla podcast icon. The new owners of Revision 3 and Tekzilla closed the podcast and fired the entire staff except for one young woman with obvious attributes designed to attract 20-something tech geek guys. (She’s also very smart, by the way.) Well, Shannon appeared on a Tekzilla Daily this morning looking very uncomfortable. She was talking about how great this news was as I thought, “Hmm, Toyota has been a sponsor of Tekzilla.” Sure enough, this special report on a dead podcast channel was sponsored by, you guessed it, Toyota.]

Patents

I am not in Las Vegas, so this news comes primarily from Toyota’s press release.

Toyota will invite royalty-free use of approximately 5,680 fuel cell related patents held globally, including critical technologies developed for the new Toyota Mirai. The list includes approximately 1,970 patents related to fuel cell stacks, 290 associated with high-pressure hydrogen tanks, 3,350 related to fuel cell system software control and 70 patents related to hydrogen production and supply.

“At Toyota, we believe that when good ideas are shared, great things can happen,” said Bob Carter, Senior Vice President of Automotive Operations at Toyota Motor Sales, USA Inc. “The first generation hydrogen fuel cell vehicles, launched between 2015 and 2020, will be critical, requiring a concerted effort and unconventional collaboration between automakers, government regulators, academia and energy providers. By eliminating traditional corporate boundaries, we can speed the development of new technologies and move into the future of mobility more quickly, effectively and economically.”

Toyota notes that it has a long history of opening its intellectual properties through collaboration, and was instrumental in facilitating the widespread adoption of hybrid vehicles by licensing related patents. This announcement represents the first time that Toyota has made its patents available free of charge and reflects the company’s aggressive support for developing a hydrogen-based society.

This Toyota initiative builds on previous commitments, including substantial financial support for the development of a hydrogen-fueling infrastructure in California and the northeastern United States. In May 2014, Toyota announced a $7.3 million loan to FirstElement Fuels to support the operations and maintenance of 19 hydrogen fueling stations across California. In November 2014, Toyota announced a collaboration with Air Liquide to develop and supply a phased network of 12 state-of-the-art hydrogen stations targeted for New York, New Jersey, Massachusetts, Connecticut and Rhode Island.

The hydrogen fuel cell patents will be made available to automakers who will produce and sell fuel cell vehicles, as well as to fuel cell parts suppliers and energy companies who establish and operate fueling stations, through the initial market introduction period, anticipated to last until 2020. Companies working to develop and introduce fuel cell busses and industrial equipment, such as forklifts, are also covered. Requests from parts suppliers and companies looking to adapt fuel cell technology outside of the transportation sector will be evaluated on a case-by-case basis.

by Gary Mintchell | Jan 5, 2015 | News

BLS Statistics

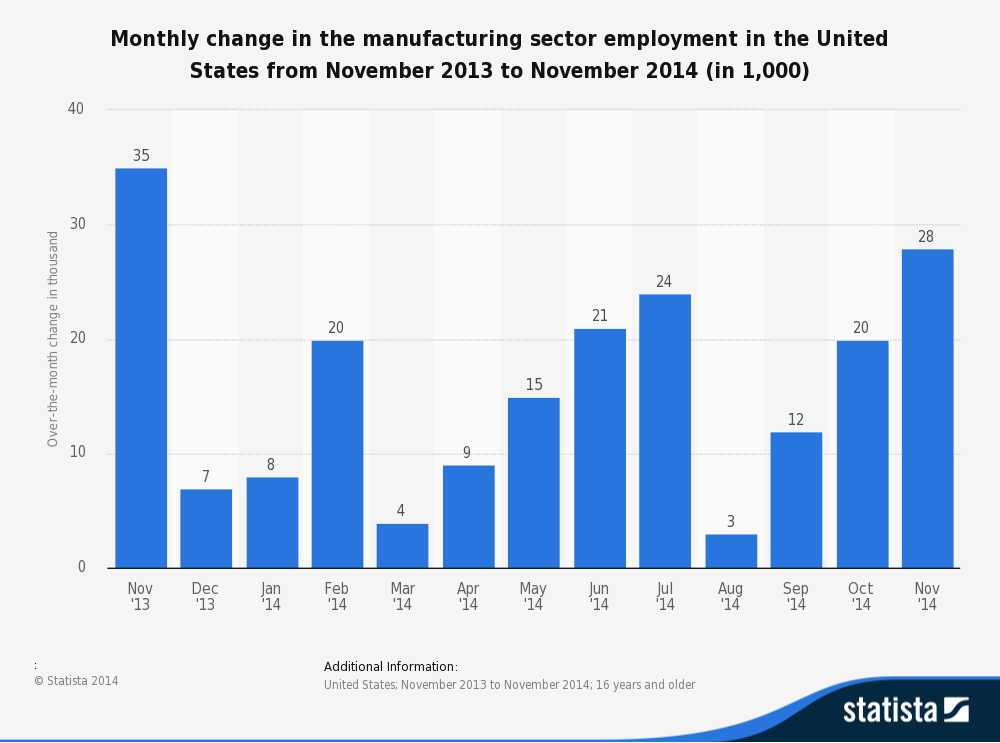

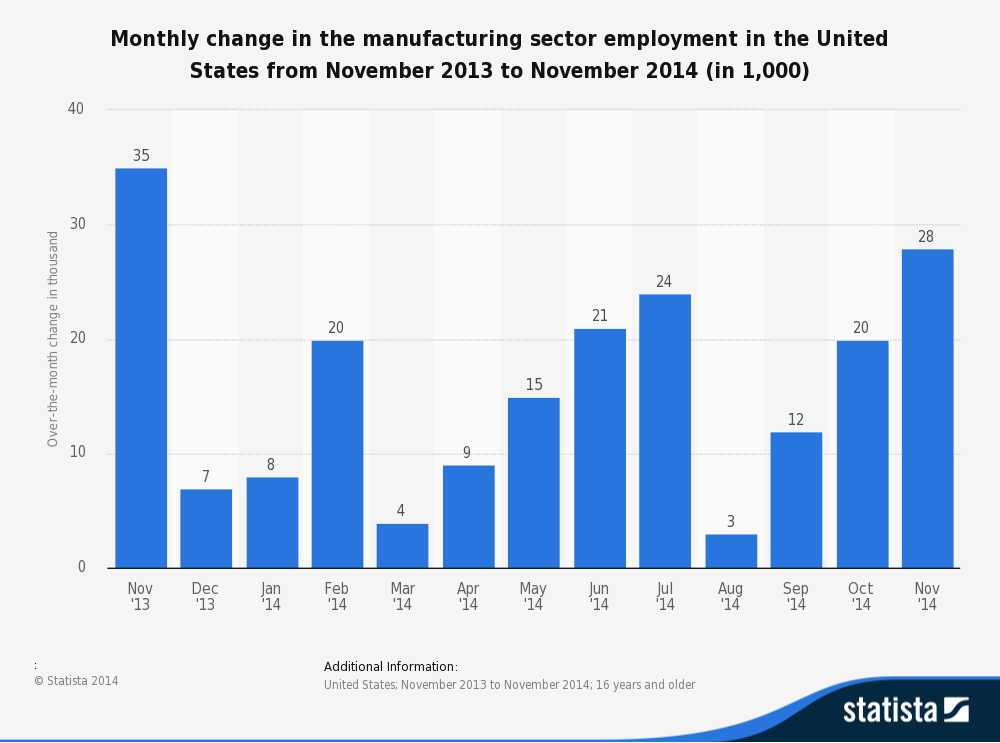

This statistic from the US Bureau of Labor Statistics shows the monthly change in the manufacturing sector employment in the United States. The data are seasonally adjusted. According to the BLS, the data is derived from the Current Employment Statistics (CES) program which surveys each month about 140,000 businesses and government agencies, representing approximately 440,000 individual worksites, in order to provide detailed industry data on employment. In the goods-producing sector, manufacturing increased by 28,000 in November 2014.

This statistic from the US Bureau of Labor Statistics shows the monthly change in the manufacturing sector employment in the United States. The data are seasonally adjusted. According to the BLS, the data is derived from the Current Employment Statistics (CES) program which surveys each month about 140,000 businesses and government agencies, representing approximately 440,000 individual worksites, in order to provide detailed industry data on employment. In the goods-producing sector, manufacturing increased by 28,000 in November 2014.

The Fed

The news from the Federal Reserve was also good.

Industrial production increased 1.3 percent in November after edging up in October; output is now reported to have risen at a faster pace over the period from June through October than previously published. In November, manufacturing output increased 1.1 percent, with widespread gains among industries. The rise in factory output was well above its average monthly pace of 0.3 percent over the previous five months and was its largest gain since February. In November, the output of utilities jumped 5.1 percent, as weather that was colder than usual for the month boosted demand for heating. The index for mining decreased 0.1 percent. At 106.7 percent of its 2007 average, total industrial production in November was 5.2 percent above its year-earlier level. Capacity utilization for the industrial sector increased 0.8 percentage point in November to 80.1 percent, a rate equal to its long-run (1972–2013) average.

Manufacturing output rose 1.1 percent in November, and the rates of change for prior months are stronger than reported previously. Factory output is now estimated to have been above its late-2007 pre-recession peak in both October and November. In November, the indexes for both durables and nondurables increased more than 1 percent, and the output of every major industry group increased or remained unchanged. Among durable goods industries, the output of motor vehicles and parts jumped 5.1 percent as a result of an increase of 900,000 units at an annual rate in total motor vehicle assemblies. Miscellaneous manufacturing, wood products, and machinery each recorded gains exceeding 1 percent. Among nondurable goods industries, output advances of more than 2 percent were registered by petroleum and coal products and by apparel and leather. The indexes for food, beverage, and tobacco products and for plastics and rubber products both increased 1.4 percent.

The capacity utilization rate for manufacturing moved up 0.8 percentage point in November to 78.4 percent, a rate 0.3 percentage point below its long-run average. The operating rates for nondurable goods and durables goods increased, and the rate for other manufacturing (non-NAICS) remained unchanged. The utilization rate for mines fell 0.8 percentage point to 87.9 percent, while the rate for utilities increased 3.9 percentage points to 82.4 percent.

by Gary Mintchell | Jan 2, 2015 | Automation, Internet of Things, Manufacturing IT, News, Operations Management, Organizations, Standards, Technology

Last month, the Obama administration announced another smart manufacturing initiative through a “Notice of Intent to Issue FOA.” That is a “Funding Opportunity Announcement.” This follows another initiative in which the Smart Manufacturing Leadership Coalition was awarded funds to develop several test beds.

Last month, the Obama administration announced another smart manufacturing initiative through a “Notice of Intent to Issue FOA.” That is a “Funding Opportunity Announcement.” This follows another initiative in which the Smart Manufacturing Leadership Coalition was awarded funds to develop several test beds.

In government-speak:

DE-FOA-0001262: Notice of Intent to Issue FOA entitled “Clean Energy Manufacturing Innovation Institute on Smart Manufacturing: Advanced Sensors, Controls, Platforms, and Modeling for Manufacturing” (DE-FOA-0001263)

The purpose of this Notice of Intent is to provide potential applicants advance notice that the Advanced Manufacturing Office (AMO), on behalf of the DOE Office of Energy Efficiency and Renewable Energy (EERE), intends to issue a Funding Opportunity Announcement (FOA) entitled “Clean Energy Manufacturing Innovation Institute on Smart Manufacturing: Advanced Sensors, Controls, Platforms, and Modeling for Manufacturing” (DE-FOA-0001263).

This Notice is issued so that interested parties are aware of the EERE’s intention to issue this FOA in the near term. All of the information contained in this Notice is subject to change. EERE may issue a FOA as described herein, may issue a FOA that is significantly different than the FOA described herein, or DOE may not issue a FOA at all.

NO APPLICATIONS WILL BE ACCEPTED THROUGH THIS NOTICE. Please do not submit questions or respond to this Notice of Intent. Prospective applicants to the FOA should begin developing partnerships, formulating ideas, and gathering data in anticipation of the issuance of this FOA. It is anticipated that this FOA will be posted to EERE eXCHANGE early in the year 2015.

FOA Documents

This announcement was accompanied by a release from the White House tying funding to enhancing US manufacturing export capability. The announcement reads:

[On December 11, 2014], at a meeting of the President’s Export Council (PEC), President Obama announced nearly $400 million to help improve the competitiveness of American businesses and workers by spurring new manufacturing innovations and giving America workers additional opportunities to improve and expand their skill sets for middleclass jobs.

To help support new advancements in manufacturing, the President will announce more than $290 million in public-private investment for two new Manufacturing Innovation Hub Competitions. The announcement fulfills the President’s 2014 State of the Union pledge to launch four new institutes this year, for a total of eight institutes launched so far, and puts the Administration past the halfway mark on the President’s original goal of creating 15 manufacturing innovation institutes supported through executive action.

In addition, the President will announce $100 million to expand apprenticeships for American workers – a proven training strategy for workers to learn the skills that employers need for American businesses to grow and thrive in a competitive global environment. Apprenticeships are also a path to the middle class – 87 percent of apprentices are employed after completing their programs and the average starting wage for apprenticeship graduates is over $50,000.

During the meeting, President Obama will also highlight the continued need to reform and simplify our tax code and the importance of opening up new markets abroad for American-made goods and services through tough, fair new trade agreements.

The PEC, chaired by Jim McNerney, President and CEO of Boeing and vice-chaired by Ursula Burns, Chairman and CEO of the Xerox Corporation, is the principal national advisory committee for exporting. The Council advises the President on government policies and programs that affect U.S. trade performance; promotes export expansion; and provides a forum for discussing and resolving trade-related problems among the business, industrial, agricultural, labor, and government sectors.

Last year, the United States exported $2.3 trillion dollars of goods and services, an all-time high, and today, exports support more than 11 million American jobs across 300,000 businesses. Manufacturing, in particular, is the engine behind our exports and innovation – contributing the majority of the nation’s exports and nearly three-quarters of its private-sector R&D. And American manufacturing is more competitive than it has been in decades, growing nearly twice as fast as the economy overall and adding 764,000 jobs since February 2010.

At the same time, businesses looking to move production to the United States consistently cite the skills of America’s workers, the most productive workforce in the world, as the reason for rooting jobs and investment here. These announcements build on that competitive strength by investing in manufacturing innovation and upgrading the skills of American workers through the proven model of apprenticeships.

Manufacturing Institutes

Manufacturing institutes serve as a regional hub, bridging the gap between applied research and product development by bringing together companies, universities and other academic and training institutions, and Federal agencies to co-invest in key technology areas that encourage investment and production in the U.S. This type of “teaching factory” provides a unique opportunity for education and training of students and workers at all levels, while providing the shared assets to help small manufacturers and other companies access the cutting-edge capabilities and equipment to design, test, and pilot new products and manufacturing processes.

Department of Energy-led Smart Manufacturing Innovation Institute

A third of the nation’s energy consumption goes into manufacturing. New smart manufacturing technologies – including advanced sensors and sophisticated process controls – can dramatically improve energy efficiency in manufacturing, saving manufacturers costs and conserving the nation’s energy.

The Department of Energy will lead a competition for a new public-private manufacturing innovation institute focused on smart manufacturing, including advanced sensors, control, platforms, and models for manufacturing. By combining manufacturing, digital, and energy efficiency expertise, technologies developed by the institute will give American manufacturers unprecedented, real-time control of energy use across factories and companies to increase productivity and save on energy costs.

For energy intensive industries – like chemical production, solar cell manufacturing, and steelmaking – these technologies can shave 10-20% off the cost of production. The new institute will receive a federal investment of $70 million that will be matched by at least $70 million in private investments and represents a critical step in the Administration’s effort to double U.S. energy efficiency by 2030.