by Gary Mintchell | Jan 9, 2017 | Internet of Things

Much is written about the Industrial Internet of Things, but is anyone really doing anything with it?

Well, yes, it is real and solving business problems for manufacturers. But too few are taking advantage of leveraging the technology for achieving business benefit. I have been in sessions with managers and engineers seeking a plan of implementation.

So last week I welcomed in the New Year with a conversation with Maciej (Mah-chek) Kranz, author of “Building the Internet of Things: Implement New Business Models, Disrupt Competitors, Transform Your Industry.”

So last week I welcomed in the New Year with a conversation with Maciej (Mah-chek) Kranz, author of “Building the Internet of Things: Implement New Business Models, Disrupt Competitors, Transform Your Industry.”

Kranz, Vice President of the Corporate Strategic Innovation Group at Cisco Systems, leads the team focused on incubating new businesses, accelerating internal innovation, and driving co—innovation with customers, partners, and startups. Prior to this he was General Manager of Cisco’s Connected Industries Group, where he drove IoT businesses for key industrial markets.

Kranz, Vice President of the Corporate Strategic Innovation Group at Cisco Systems, leads the team focused on incubating new businesses, accelerating internal innovation, and driving co—innovation with customers, partners, and startups. Prior to this he was General Manager of Cisco’s Connected Industries Group, where he drove IoT businesses for key industrial markets.

He told me that he wants people to understand the changes coming due to the IIoT and make the book practical and helpful. He succeeded in that goal. The book contains many examples of Industrial Internet of Things in practice along with practical leadership and implementation advice. While there is some technical discussion, this is not a book for engineering rather it is targeted to line of business leaders, people who solve business problems, and IT leaders as well as engineering leadership.

As I read the book, though, I got the impression that much of what Kranz is calling IIoT was once called “manufacturing IT.” Such is the morphing of terminology.

I have talked with leaders who are trying to build business cases and implement an Industrial Internet of Things strategy. Their experiences merge with Kranz’ observations that the biggest barrier to implementation is cultural. Any of us who are change agents and have tried implementing new technologies and new ways of working can show the scars earned from learning that barrier the hard way.

But the potential benefits are huge. For example, this quote from an executive of Harley Davidson, “What used to take a painfully long time to triage and troubleshoot now can be accomplished in a single morning,” the manager said, “An order of magnitude improvement.”

Kranz is not bashful about proclaiming why you should implement IIoT—“Like it of not, the Internet of Things (IoT) will change your organization unlike anything before. It isn’t just the next big thing. IoT is the future.”

He continues, “The real payoff from IoT comes down to automating existing processes that have a large labor or time component and streamlining the related process in one way or another.”

Here is another quote from the book, “You belong to Generation IoT if you embrace open standards, open collaboration, open communications, and open, flexible business models and you’re willing to assemble a comprehensive partner ecosystem to build and deploy agile, flexible business solutions.”

On the practical side, here are his eight elements of success

- Start with strategy, planning, and preparation.

- Secure C-suite sponsorship

- Build a diverse team

- Communicate and drive IT/OT convergence

- Rethink operations from the ground up

- Design for flexibility

- Educate and train

- Revisit repeatedly-it’s not a one-and-done effort

Kranz concludes with words that echo my belief in Lean—that it isn’t a strategy but more of a way of life. He says, “Most importantly, my hope is that IoT will change the way you think about your business, and how you’ll design, plan, develop, and deliver products and services, go to market, and interact with customers.”

by Gary Mintchell | Dec 19, 2016 | Internet of Things, News, Operations Management, Organizations

Collaboration rules the technical world. A professor who influenced me greatly was ex-CIA (ex?). He would proclaim in our international politics classes during the height of the Cold War that politicians might want to close borders, but scientists would never allow it. “Scientists want to publish their findings,” he would say, “so they will publish and leave out a step in the mathematical proof. It would get past censors, but fellow scientists around the world would figure out the missing steps.”

Our world today is rife with politicians trying to close borders. No, it’s not only Trump in America.

Given the political times, I’m encouraged by all the technology collaboration I see. Last week I posted a year end update by Tom Burke of the OPC Foundation highlighting his work in collaborating with other standards bodies. I have been working with MIMOSA (and recently elected Chief Marketing Officer). This organization has also been working with a variety of organizations.

Last week came news of another collaboration. The Industrial Internet Consortium (IIC), the global, member-supported organization that promotes the accelerated growth of the Industrial Internet of Things (IIoT), announced it has signed a memorandum of understanding (MoU) with the China Academy of Information and Communications Technology (CAICT).Under the agreement, the IIC and CAICT will work together to help ensure interoperability for the industrial Internet in China.

Last week came news of another collaboration. The Industrial Internet Consortium (IIC), the global, member-supported organization that promotes the accelerated growth of the Industrial Internet of Things (IIoT), announced it has signed a memorandum of understanding (MoU) with the China Academy of Information and Communications Technology (CAICT).Under the agreement, the IIC and CAICT will work together to help ensure interoperability for the industrial Internet in China.

The agreement is one of a number of agreements made by the IIC’s newly formed Liaison Working Group.

Joint activities between the IIC and CAICT will include:

- Identifying and sharing best practices

- Collaborating on testbeds and research and development projects

- Realizing interoperability by harmonizing architecture and other elements

- Collaborating on standardization

“We look forward to working with the China Academy of Information and Communications Technology to help further the development of the industrial Internet throughout China,” said Wael William Diab, Chair, IIC Liaison Working Group and Senior Director, Huawei. “We’re especially excited about joint activity on testbeds and research and development projects that will help advance the adoption of the industrial internet.”

“We highly value the cooperation between CAICT and the IIC,” said Mr. Xiaohui YU, CTO of CAICT. “The collaboration with the IIC will help establish tight relationships between the IIC and Chinese entities and organizations, such as the AII Alliance, and will develop, facilitate and enhance the industrial Internet.”

The Liaison Working Group is the gateway for formal relationships with standards and open-source organizations, consortia, alliances, certification and testing bodies and government entities/agencies.

China Academy of Information and Communications Technology (CAICT) is a research academy under the Ministry of Industry and Information Technology with over 2,400 employees. A specialized think-tank for the government, and an innovation and development platform for the industry, CAICT holds a service portfolio that covers the areas of information and communication technology, the integration of ICT and industries, such as 5G, Internet IoT and industrial Internet, cloud computing, big data, Intelligent manufacturing etc.

As a leading think-tank and platform in ICT field of China, it contributes to the development and innovation of the country and the ICT industry by providing support and services in terms of national strategies, plans, policies, standards, technology labs, testing and certification etc. CAICT is the national core supporting organization for industrial Internet, intelligent manufacturing and Internet relevant actions to the Chinese government, and is involved in the drafting of the “Internet+ action plan,” “Made in China 2025,”and other national strategies and guidance on IoT, Cloud computing, big data and Broadband China, etc. CAICT is currently the leading organization to promote the development of industrial Internet of China.

The Industrial Internet Consortium is a global, member-supported, organization that promotes the accelerated growth of the Industrial Internet of Things by coordinating ecosystem initiatives to securely connect, control and integrate assets and systems of assets with people, processes and data using common architectures, interoperability and open standards to deliver transformational business and societal outcomes across industries and public infrastructure. The Industrial Internet Consortium is managed by the Object Management Group (OMG).

by Gary Mintchell | Nov 30, 2016 | Internet of Things, Operations Management

Have we reached a choke point in the IIoT platform currently in vogue? Glen Allmendinger, founder of Harbor Research, studies the area of connectivity. He continues to move with the times–perhaps even ahead of the times–going from M2M to IoT to (now) Smart Systems.

We should all know by now that the Internet of Things isn’t a Thing. The term was no doubt coined to capture the idea of connecting smart devices over the Internet using Internet protocols. There is a consumer aspect and an industrial aspect to the term. GE coined “Industrial Internet” (although it does not seem to care if the term gains widespread use) which then gave us “Industrial Internet of Things.” Some people then try to merge the term with the German initiative Industrie 4.0. But the only core similarity lies in a foundation of digital technology.

Allmendinger writes in a recent essay about the “failure of IoT platforms.” He is on to a key thought, here. He’s discussing network architecture as much as platforms. Specifically, he sees the failure of client/server architecture to scale and achieve required flexibility. We might as well exploit the power of the cloud and peer-to-peer. I tend to like publish/subscribe. I’m thrilled to see OPC Foundation moving to a pub/sub architecture, for example. Now if it, as well as other standards, would move to REST from SOAP, things would be better.

I’ve included a few excerpts from Allmendinger’s essay. Check out the entire piece here.

Today, platforms for the Internet of Things are still a kludgy collection of yesterday’s technology and architectures that do not address the most basic development challenges.

Today the world of smart communicating devices is mostly organized in hierarchies with smart user interface devices at the top and the dumb devices [often analog or serial sensors and actuators] at the bottom. Within this structure, there are typically various types of “middle box” supervisory and gateway devices forming a point of connectivity and control for the sensors and actuators as well as the infrastructure for the network. From our perspective, this description of today’s IoT systems architecture looks very familiar and is largely organized like client-server based computer systems….. no surprise given they were designed in the 1990′s.

As the Internet of Things opportunity matures, the sensor and actuator devices will all become smart themselves and the connectivity between them (devices, for the most part, that have never been connected) will become more intelligent and the interactions more complex. As the number of smart devices grow, the existing client-server hierarchy and the related “middle boxes” acting as hubs, gateways, controllers and interfaces will quickly start to blur. In this future-state, the need for any kind of traditional client-server architecture will become superfluous. In a future Smart Systems world, the days of hierarchical models are numbered.

This is the move we’ve been waiting for…….. to a truly distributed architecture because today’s systems will not be able to scale and interact effectively where there are billions of nodes involved. The notion that all these “things” and devices will produce streaming data that has to be processed in some cloud will simply not work. It makes more sense structurally and economically to execute these interactions in a more distributed architecture near the sensors and actuators where the application-context prevails.

Dispersed computing devices will become unified application platforms from which to provide services to devices and users where the applications run, where the data is turned into information, where storage takes place, and where the browsing of information ultimately takes place too – not in some server farm in a cloud data center.

From our view the movement towards peer-to-peer, and the view that many people hold that this is somehow novel, is ironic given that the Internet was originally designed for peer-to-peer interactions. We seem to be heading “back to the future.”

Today’s platforms for Smart Systems and the IoT should be taking on the toughest challenges of interoperability, information architecture and user complexity. But they’re not.

We need to creatively evolve to an entirely new approach that avoids the confinements and limitations of the today’s differing platforms. We need to quickly move to a “post platform” world where there is a truly open data and information architecture that can easily integrate diverse machines, data, information systems and people – a world where smarter systems will smoothly interact to create systemic intelligence – a world where there are no artificial barriers between different types of information.

by Gary Mintchell | Nov 29, 2016 | Automation, Internet of Things, Networking, Operations Management

What is an “edge” device in terms of network architecture for today’s Industrial Internet of Things? Classical networking practice has had it’s definition. But how do you extend the definition in today’s industrial networks with perhaps thousands of devices at the edge? Do you label all those smart devices as edge?

I have been spending much time with Dell Technologies and its IoT division. It has built a computing device with a multitude of connection ports, data storage, and computing capability. This device is named Gateway, but it is labeled as an edge device. Meanwhile I interviewed two GE Automation and Controls executives who labeled controllers (PLCs) as edge devices.

I ran across this article by ARC Advisory Group’s Greg Gorbach. I’ve quoted some of it below. You can read it in its entirety here. He analyzes a number of points of view. Does it all matter to you what is called an edge device? How do you configure a modern IIoT network?

Power of Edge – Greg Gorbach

What is the industrial edge, and why does it matter? Is it network infrastructure? Can the edge be found in a sensor that feeds a controller in a plant? Or is it in a smart machine that’s in service halfway around the globe?

In networking, an edge device is a device which provides an entry point into enterprise or service provider core networks. Examples include routers, routing switches, integrated access devices, multiplexers, and a variety of local area network (LAN) and wide area network (WAN) access devices. Edge devices also provide connections into carrier and service provider networks. Network providers and others have been pushing intelligence – compute power and the ability to run applications and analytics – to these edge devices for some time.

But the growth of the Industrial Internet of Things (IIoT) extends the ‘edge’ beyond the network devices, into industrial and commercial devices, machines, and sensors which connect to the network. Edge computing and analytics can, often should be, and increasingly is close to the machines and data sources. As the digitization of industrial systems proceeds, we expect that analysis, decision-making, and control will be physically distributed among edge devices, the network, the cloud, and connected systems, as appropriate.

These functions will end up where it makes most sense for them to be.

IIoT will change the way industrial organizations generate, collect, and analyze data. Data will be generated faster and in greater volume than ever before. This will require today’s plant information infrastructure to evolve. One part of this new infrastructure will be intelligent edge devices, which will include the latest generation of controllers, such as DCS’s, PLC’s and PACs. Besides providing control, these edge devices will securely collect, aggregate, filter, and relay data, leveraging their close proximity to industrial processes or production assets. They will also be capable of collaborating with powerful analytics tools, detecting anomalies in real time, and raising alarms so that operators can take appropriate actions.

With edge computing and analytics, data is processed near the source, in sensors, controllers, machines, gateways, and the like. These systems may not send all data back to the cloud, but the data can be used to inform local machine behaviors as it is filtered and integrated. The edge systems may decide what gets sent, where it gets sent and when it gets sent.

Placing intelligence at the edge helps address problems often encountered in industrial settings, such as oil rigs, mines, chemical plants, and factories. These include low bandwidth, low latency, and the perceived need to keep mission critical data on site to protect IP.

As you think about digitizing and transforming your industrial operations or your products and services, pay special attention to the edge. Consider the optimal location for analysis, decision-making, and control, and the best way to distribute these among edge devices, the network, the cloud, and other connected systems.

by Gary Mintchell | Nov 29, 2016 | Internet of Things, News, Operations Management, Organizations, Standards

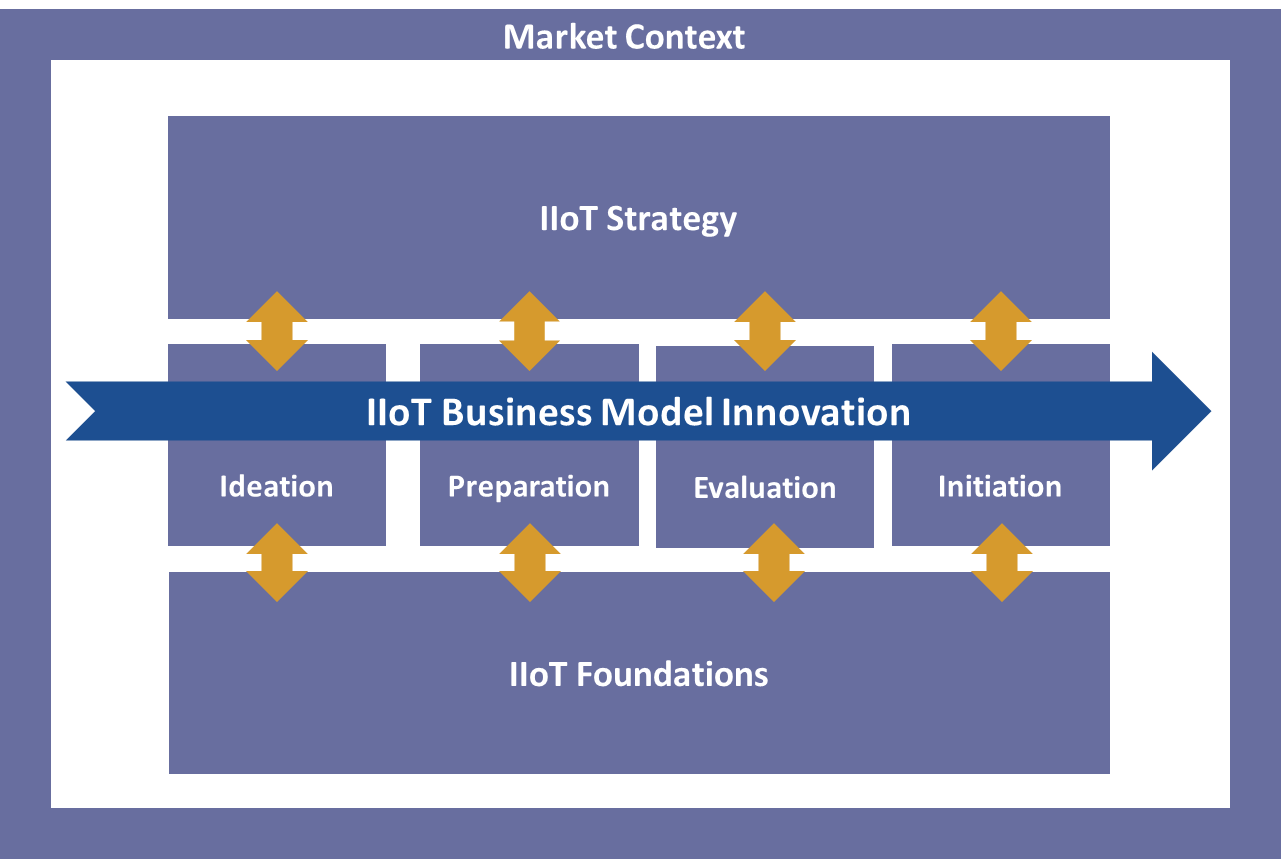

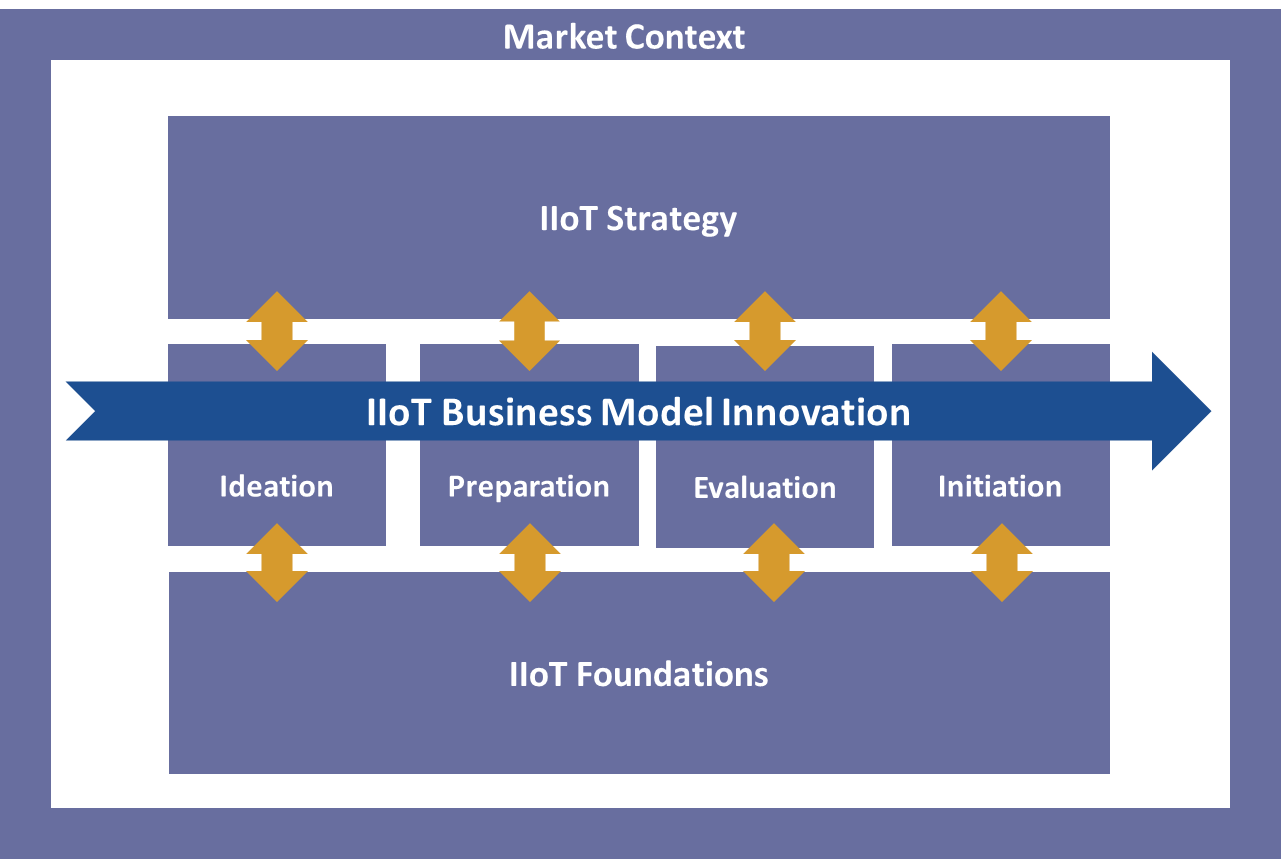

IIoT Business Model

In another advancement for the Industrial Internet of Things, The Industrial Internet Consortium (IIC), the global, member-supported organization that promotes the accelerated growth of the Industrial Internet of Things (IIoT), announced the publication of the Business Strategy and Innovation Framework (BSIF). The BSIF helps enterprises to identify and analyze issues that must be addressed to capitalize on the opportunities emerging within the IIoT.

“Everybody knows that the Industrial Internet of Things will completely transform the way that business works. What’s not clear is exactly how to deploy these new IIoT concepts to best effect,” said Jim Morrish, Chair of the Business Strategy Task Group, and Founder and Chief Research Officer, Machina Research. “What the IIC’s Business Strategy and Innovation Framework provides is a toolkit for identifying, prioritizing and initiating the deployment of those crucial IIoT initiatives. It’s a significant step forward for the IIoT industry in terms of working to capitalize on the huge opportunities presented by this new technology wave.”

The BSIF serves as a reference document for chief executives in enterprises planning to engage in IIoT concepts. A single-source compendium of the issues and challenges enterprises should consider before they deploy IIoT initiatives, the BSIF details frameworks and concepts to help enterprises increase value for users, customers and partners while at the same time helping to reduce market and technical uncertainties.

The BSIF outlines a comprehensive set of best practices for companies engaging in IIoT, but companies are free to adopt a lighter touch or use an existing internal project model, especially within smaller companies. Alternatively, a range of project support processes may already be in place and the approach documented in the BSIF may be used to enhance existing infrastructures to address new IIoT opportunities (particularly for larger companies).

“The IIC’s Business Strategy and Innovation Framework is an important industry milestone,” said Jim Nolan, EVP, IoT Solutions, InterDigital. “It offers timely, strategic guidance to the many organizations that are beginning to implement IIoT solutions.”

The BSIF is the most in-depth Industrial IoT-focused business strategy framework comprising expert vision, experience and business strategy best practices from IIC members, including Bosch Software Innovations, InterDigital, Hewlett Packard Enterprise, and Machina Research. The BSIF is available free of charge. For more information about the BSIF, click here.

The Business Strategy and Innovation Framework provides a high-level identification and analysis of issues that any enterprise will need to address to capitalize on the opportunities emerging from this current revolution that is the IIoT. This comprehensive document is a product of the Business Strategy Task Group, a strategy-focused task group within the Industrial Internet Consortium’s Business Strategy and Solution Lifecycle Working Group.

The Business Strategy and Innovation Framework describes the requirements to succeed in IIoT:

- An IIoT strategy and goals

- A structured framework to target and select the right IIoT opportunities

- A system in place to identify, assess and initiate IIoT opportunities

IIoT requires enterprises to rethink their current business models. This is necessary regardless of whether they actually adopt IIoT solutions internally: Industry is moving toward IIoT adoption, and enterprises that keep pace with this trend will undoubtedly have a strong competitive advantage.

Contributors to the Business Strategy and Innovation Framework dedicated their valuable time and expertise in authoring, editing and other ways. In particular, we would like to thank the following contributing members and their organizations:

- Veronika Brandt – Bosch Software Innovations

- Ken Figueredo – InterDigital, Inc.

- Steve Haldeman – Hewlett Packard Enterprise

- Jim Morrish – Machina Research, Chair of the Industrial Internet Consortium Business Strategy Task Group

So last week I welcomed in the New Year with a conversation with Maciej (Mah-chek) Kranz, author of “Building the Internet of Things: Implement New Business Models, Disrupt Competitors, Transform Your Industry.”

So last week I welcomed in the New Year with a conversation with Maciej (Mah-chek) Kranz, author of “Building the Internet of Things: Implement New Business Models, Disrupt Competitors, Transform Your Industry.” Kranz, Vice President of the Corporate Strategic Innovation Group at Cisco Systems, leads the team focused on incubating new businesses, accelerating internal innovation, and driving co—innovation with customers, partners, and startups. Prior to this he was General Manager of Cisco’s Connected Industries Group, where he drove IoT businesses for key industrial markets.

Kranz, Vice President of the Corporate Strategic Innovation Group at Cisco Systems, leads the team focused on incubating new businesses, accelerating internal innovation, and driving co—innovation with customers, partners, and startups. Prior to this he was General Manager of Cisco’s Connected Industries Group, where he drove IoT businesses for key industrial markets.

Last week came news of another collaboration. The

Last week came news of another collaboration. The