by Gary Mintchell | Jan 27, 2017 | Commentary

Ah, the warmth. It feels so good. Is it getting warmer? I’m not sure, but the warmth eases muscle stress. Frees the joints. And it gets warmer.Then, it’s too hot.

It could be the proverbial frog being slowly boiled. Or it could be me in the steam room.

Or it could be any of us in our organization.

How easily we don’t notice we’re not growing anymore. We’re not developing new services for our customer.

We just sort of gently slid into the routine.

Same people. We’re comfortable with them. No one around to upset things with new ideas.

We’re comfortable with the same surroundings. We enter and everything is familiar. We feel like we belong. We don’t notice the things that would turn off an outsider–or our customer.

What was our mission again? I sort of forget. I know it’s printed somewhere. Probably posted on a wall that has just become part of the environment.

It feels so good to be comfortable.

But…

Is that what we are placed here on Earth to experience? Is that what our stockholders or owners expect? Is that what our customers expect?

Or are we supposed to push through comfort? Find that place of discomfort that impels us toward fulfilling a mission.

What was that valuable service to people that gave passion to the founders?

Was it designing and making a product that will bring joy, relief, health to others?

Where are the big ideas that our technology can use to contribute to the growth and development of society?

“There are three types of people in this world: those who make things happen, those who watch things happen, and those who wonder what happened.”

Which are you? Are you a change agent? Or are you a frog in the pot of boiling water?

by Gary Mintchell | Jan 26, 2017 | Automation, Industrial Computers, Security

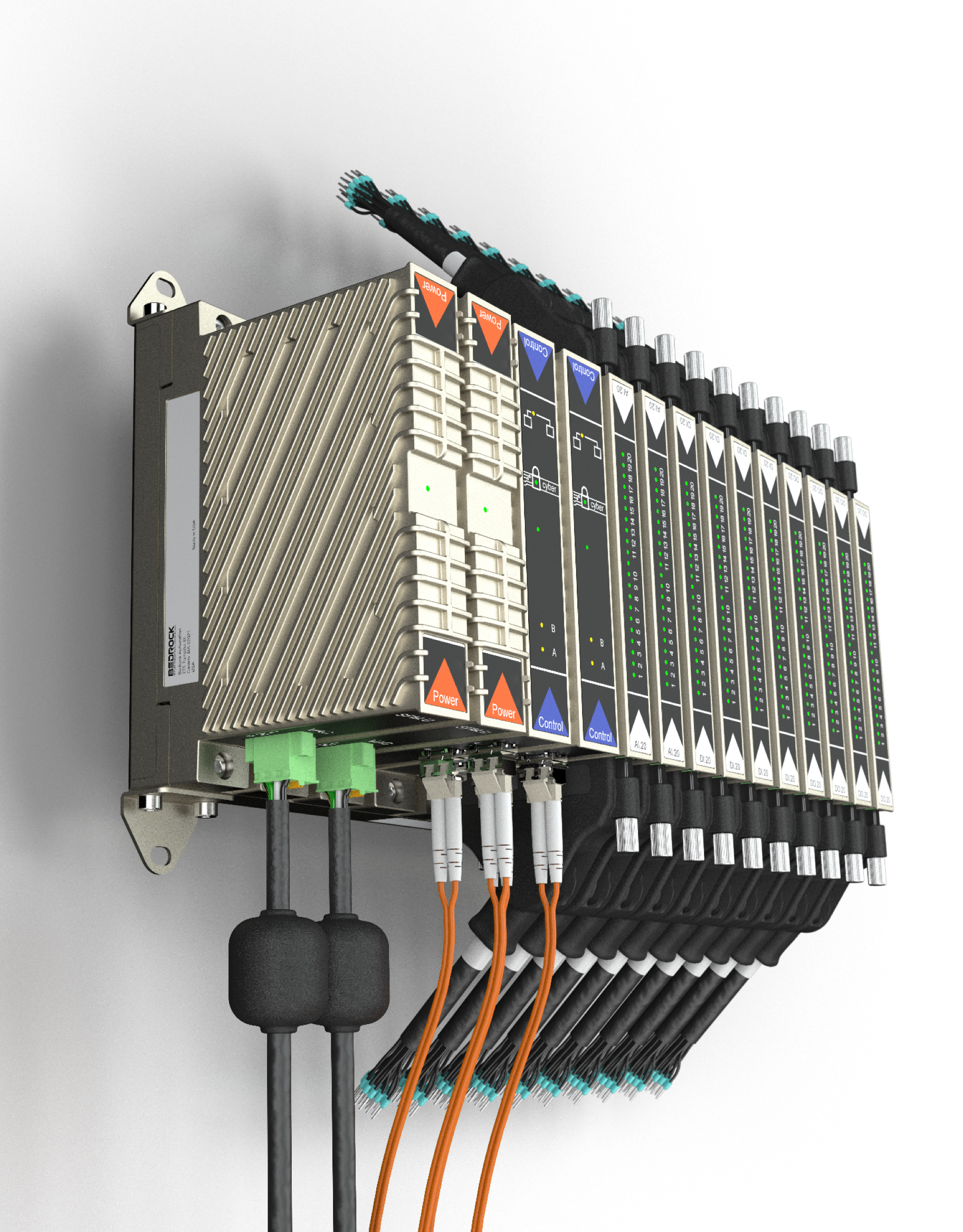

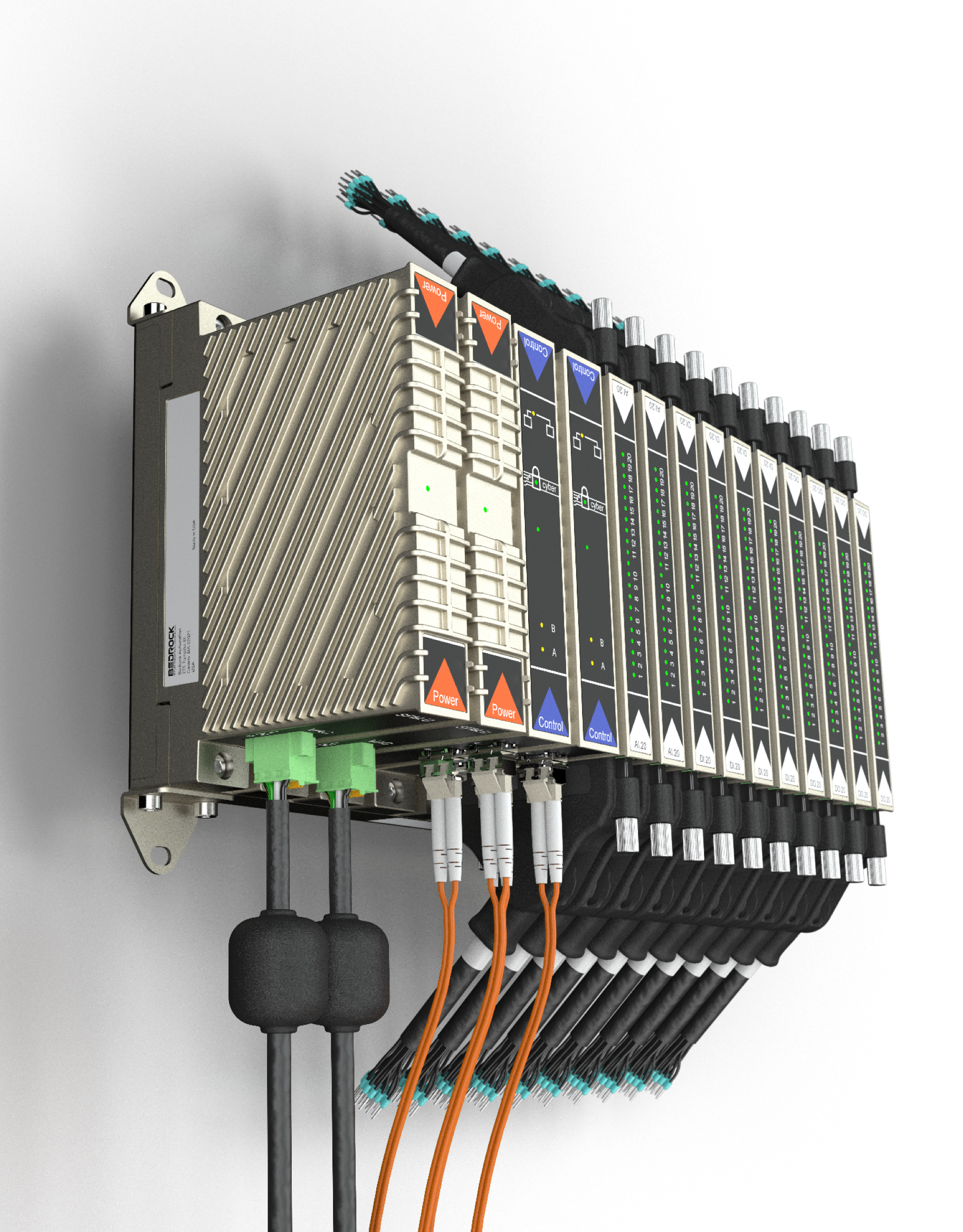

Bedrock Automation has built a good automation platform with built-in security and toughness. I’ve been watching to see just how disruptive it might be in the market. In this announcement, it is showing further growth in its go-to-market strategy of working with integrators. It has signed a memorandum of agreement with Jacobs Engineering Group Inc., one of the world’s largest and most diverse providers of full-spectrum technical, professional and construction services. Under the agreement, the companies will pursue selected projects with automation system requirements for potential implementation of the Bedrock Open Secure Automation (OSA) system.

Bedrock Automation has built a good automation platform with built-in security and toughness. I’ve been watching to see just how disruptive it might be in the market. In this announcement, it is showing further growth in its go-to-market strategy of working with integrators. It has signed a memorandum of agreement with Jacobs Engineering Group Inc., one of the world’s largest and most diverse providers of full-spectrum technical, professional and construction services. Under the agreement, the companies will pursue selected projects with automation system requirements for potential implementation of the Bedrock Open Secure Automation (OSA) system.

“Our clients are increasingly concerned about both cyber security and advanced automation and we have been creating innovative service packages to meet these needs. Bedrock Automation has excellent experience and superior designs in this area. I am impressed with their comprehensive background and knowledge in the industrial DCS and PLC arena,” said Jacobs’ Mission Solutions Chief Technology Officer Dr. Tommy Gardner.

The Bedrock control system is known for its patented Black Fabric Cybershield architecture, which provides an intrinsic cyber secure automation platform to protect user hardware, software and applications. Unlike other conventional industrial control systems, Bedrock was designed from a clean sheet of paper with advanced components and architecture to be simple, scalable and secure.

“Jacobs is taking a leadership role in integrating the next generation of information and automation technologies for its clients,” added Bedrock Automation President Bob Honor. “We see this as a tremendous opportunity to bring our technology and our vision of holistic cyber security to a much larger audience. We look forward to an exciting and mutually beneficial relationship with Jacobs.”

by Gary Mintchell | Jan 10, 2017 | News, Organizations

There is plenty of time to register for the 21st Annual ARC Industry Forum Industry in Transition: Realizing the Digital Enterprise February 6-9, 2017 – Orlando, Florida. I can’t believe that this will mark my 20th trip to Orlando this time of year.

There is plenty of time to register for the 21st Annual ARC Industry Forum Industry in Transition: Realizing the Digital Enterprise February 6-9, 2017 – Orlando, Florida. I can’t believe that this will mark my 20th trip to Orlando this time of year.

While in many ways this is an ARC Advisory Group “user group” meeting, almost everyone shows up. For several years now this is the one place where you can go and talk with people from many automation suppliers. And with many engineers and managers who implement and manage automation and information.

You can come to make contacts or pick up on the latest trends.

As for me, I will be looking for new companies and products, a sense of the industry’s direction, and contacts who are looking for someone to help them with things I can assist with—strategic messaging, advice on status of industry and companies, product development ideas. It will also be interesting to get an update on the ExxonMobil attempt to commoditize the DCS (I presume so that it can catch up to peers in modernizing operations). That effort has quieted during the past few months.

ARC tries very hard to limit presentations by suppliers. As technology developers, suppliers can be a source of great information. Unfortunately most of the suppliers have used the Forum in the past to simply promote their company and products. No one is paying to attend a forum to hear from marketing managers. Now if a few people from the CTO’s office spoke…

The comments below are taken from the latest ARC promotion. I see only one supplier listed in the speaker lineup so far.

Industrial companies are starting to employ ‘digitalized’ business processes and exploit the increasing convergence between operational technology (OT), information technology (IT), and engineering technology (ET) on the plant floor. How will disruptive technologies change existing products and plants? How will open source solutions impact traditional software and automation domains? Is cybersecurity a threat to digitalization? How ‘smart’ are smart machines? How do Big Data and predictive and prescriptive analytics enable operational change?

Join us to learn how the digital enterprise benefits from smarter products, new service and operating models, new production techniques, and new approaches to design and sourcing.

Check out these topics:

- Industrial Cybersecurity and Safety Analytics and Machine Learning

- Asset Performance Management

- IT/OT/ET Convergence

- Service Performance Management

- Automation Innovations

- Industrial Internet Platforms

- Connected Smart Machines

Partial List of Executive Speakers:

- S. Dept. of Homeland Security, Marty Edwards, Director ICS Cyber Emergency Response Team

- ExxonMobil Research & Engineering, Don Bartusiak, Chief Engineer, Process Control

- NOVA Chemicals, Doug Lutz, Principal Process Automation Engineer

- Savannah River Nuclear Solutions, Laura Sheets, Tritium Process Control Lead Engineer

- Local Motors, Justin Fishkin, Chief Strategy Officer

- NIST, Adam Sedgewick, Sr. Information Technology Policy Advisor

- Duke Energy, David Lawrence, Technology Development Manager, Emerging Technology

- Merck, Gene Tung, Director of IT

- WAGO, Thomas Holm, Head Innovation & Technology

- Eli Lilly, Kevin Wilhelm, Senior Consultant

- Ascend Performance Materials, Terry Unruh, Maintenance Process Leader

- Kinder Morgan, Lawrence Staab, Training Coordinator/Instructional Designer

- Georgia-Pacific, Michael Carroll, VP Innovation and Operations Excellence

- 3M, Liu Qiao, Technical Director, Software Electronics Mechanical Systems Lab

- Dow Chemical, Glen Mutscher, Global Director, Manufacturing & Engineering

- ExxonMobil Research & Engineering, Steve Bitar, R&D Program Manager

- American Society of Mechanical Engineers, Dean Bartles, Sr. Technology Advisor

- Dow Chemical, Mary Beth Seasholtz, Data Services Technical Leader

- Fluor, David Hoeppner, David Hoeppner

- Shell Global Solutions, Tyler Williams, Global Technology Leader

- Massachusetts Institute of Technology, Stuart Madnick, Professor of Information Technologies and Engineering Systems

- Albermarle, Jonathan Alexander, Operations Engineer

- AGCO, Jan Theissen, Director Strategy & Methods, Global Purchasing & Materials

- Pepsi Beverages, Jeff Russell, SE Regional Engineering Manager

by Gary Mintchell | Dec 16, 2016 | News, Operations Management, Organizations, Standards

Interoperability, standardization, and collaboration were the key words for OPC Foundation in 2016. Tom Burke, OPC Foundation President, recently recapped a busy 2016 for the Foundation. Adoption of OPC UA has been gaining momentum in the market. Collaboration with other groups is growing. And the technology is finally beginning to show significant use beyond industrial automation.

Burke says, “It has been a very exciting year. We have seen record growth in adoption of the OPC UA technology across multiple domains and vertical markets. The OPC Foundation policy of being truly open has expanded the reach of the OPC technology. The specifications are available to everyone, the technology is open sourced, and now we have opened up our certification labs to non-members.”

The OPC Foundation byline since the beginning has been recognized as the “The Interoperability Standard for Industrial Automation.” With the significant international membership growth and adoption of the OPC UA technology across multiple vertical markets the byline of the OPC Foundation has been ratified as “The Industrial Interoperability Standard.” This byline recognizes the case that OPC is no longer just for automation.

OPC UA specifications and technology are actively being deployed across global boundaries supplying the key infrastructure for everything related to the Internet of Everything (IIoT, Industrie 4.0, China 2025, IIC, M2M…); inclusive of:

- numerous testbeds with the OPC UA technology being standardized in the Industrial Internet Consortium (IIC)

- being recognized as the communication and information modeling standard for Industrie 4.0

- OPC UA being finalized as a Chinese National Standard

In May 2016, BSI (German Federal Office for Information Security) conducted a thorough security analysis of OPC UA and found it exceeded the security requirements for Industrie 4.0.

Collaboration with numerous organizations beyond industrial automation is the strategy and path forward to allow information integration from the embedded world to the cloud.

New members and new products are emerging as end users are looking for information solutions for IIoT, and the OPC UA technology is well-positioned to address the needs of the Internet of Everything.

Numerous organizations continue to partner with the OPC Foundation and/or develop companion specifications for their respective information models to seamlessly plug into OPC UA.

Organizations announcing releases of their companion specifications in 2016 for the OPC UA technology included:

• AutomationML

• PLCopen

• AIM

• VDMA: Injection Molding (status: release candidate)

• VDMA: Vision Cameras (status: in foundation)

• VDMA: Robotics, starting with the help of KUKA (status: in preparation)

VDMA is very active standardizing on OPC UA information models and expects to rollout a multitude of additional information models in 2017, leveraging OPC UA information integration communication as it’s strategy for seamless information integration and interoperability.

Board of Directors

Board members are elected as individuals for a two-year term. Elected to new 2-year terms were: Russ Agrusa, (ICONICS), Veronika Schmid-Lutz (SAP), Stefan Hoppe (Beckhoff) (also VP of OPC Foundation), and Matthias Damm (Ascolab). Also on the OPC Foundation Board of Directors are Thomas Burke (OPC Foundation), Thomas Hahn (Siemens) (also VP of OPC Foundation), Matt Vasey (Microsoft), and Ziad Kaakani (Honeywell) (also Treasurer of OPC Foundation), and Shinji Oda (Yokogawa).

by Gary Mintchell | Dec 6, 2016 | Automation, Process Control, Workforce

The war is over and we have won. The war of handheld communication devices loose in the wilds of a plant, that is. Remember only a few years ago–like maybe two–when there was much angst in the media (except from me) about bringing handheld mobile communication into the plant? Now vendors are tripping all over themselves bringing out cool new toys to help maintenance, operations, and engineering do their jobs.

Here is a new tool from ABB. ABB has taken the next step with its Field Information Manager – the first FDI based Device Management tool in the market, with the introduction of its Field Information Manager 1.1 Handheld Edition. This easy-to-use software is now available for sale. The Handheld Edition makes it possible for the user to do configuration, parametrization and diagnosis of the HART instruments in many locations – in the field, at the back of the panel / junction box or in the instrumentation laboratory.

The Field Information Manager is designed to help users be more efficient in the configuration and management of their smart devices. Users do not need to invest in proprietary handheld terminal hardware; this eliminates the extra expense of proprietary hardware and significantly reduces lifecycle maintenance costs. The Field Information Manager can be installed on any Windows tablet / laptop / computer, thereby multiple instrumentation programs can be installed on a single machine. It is very quick to install and saves time for instrument and service technicians. Users can get started in less than three minutes, and can download all needed packages and files at www.abb.com/fieldinfo at any time.

Production technology vendors are really getting wise to the modern world about online stores. Field Information Manager Store and Print device configuration allows easy transfer of parameters from one device to another and eliminates manual recording of parameters.

Other key features of the Field Information Manager Handheld Edition include: Interoperability based on FDI components Online and offline parametrization Documentation of parameters and settings Novel concepts for ease of use and navigation with touch support ABB instrumentation FDI Device Packages ready to download Generic HART Device Package for all HART devices Supports installed base – DD/EDD files Visit www.abb.com/fieldinfo to learn more.

Bedrock Automation

Bedrock Automation

There is plenty of time to register for the

There is plenty of time to register for the