by Gary Mintchell | May 17, 2018 | Internet of Things, News, Security

Amongst the cloud and manufacturing IT booths in Hannover was a sizable booth nestled in the middle housing Arm, the processor company. Here Ian Ferguson, Vice President, Ecosystem Development, met with me to discuss some of the latest embedded computing news.

Arm licenses chips which are optimized to the OS for customer companies to use and customize.

Its software business includes a device manager for small device apps for provisioning and connecting. It has also announced a bridge to IBM Watson.

Its software product, Embed, runs on ARM. Among the areas of focus is smart meters and tracking of small assets. Ferguson also mentioned smart buildings–especially lighting.

Security is a key focus working at the chip level to detect intrusions, “device health”.

News briefs:

• Rapid industry adoption of Mbed Platform with more than 300,000 developers (>30% growth over the past year) and 80 partners

• Arm expands integration with IBM Watson IoT, and partners with Cybertrust and GlobalSign to deliver BYOC (Bring-Your-Own-Certificate) flexible IoT security authentication

• Mbed drives IoT business value for logistics, utilities and smart cities as organizations shift to Industry 4.0

Help organizations take advantage of the opportunities offered by IoT data and combine this with their business data to create valuable business outcomes. However, in talking with these organizations, many feel that pursuing opportunities to achieve these business outcomes through IoT opens themselves up to more IT complexity and greater security concerns.

Security and complexity of integration are legitimate concerns that addressed with Arm Mbed Platform. This platform provides the necessary IoT building blocks including, connectivity, device management, security and provisioning with the support of a 300,000+ strong developer community that has grown more than 30% in the past year.

It’s also supported by a growing ecosystem of 80 contributing partners such as IBM, which is bridging the Mbed Cloud with IBM Watson IoT Platform. We’ve integrated Mbed Cloud with Cybertrust and GlobalSign to provide more flexible security authentication for IoT devices.

Mbed Cloud and Mbed Cloud On Premises were designed to provide device management, connectivity and provisioning that customers demand, supported across multiple public and private clouds, on-premises and hybrid environments.

IoT security should be easy to implement, not an inhibitor. The new integrations between Mbed Cloud and Cybertrust and GlobalSign enable customers to BYOC (Bring-Your-Own-Certificate) for flexible and secure IoT authentication, leveraging the public key infrastructure they already use. Security should also be built into development, which is why Arm is planning to make its free open-sourced development platform, Mbed OS, the first OS to support PSA-Compliant trusted boot, storage and opaque cryptography.

However, even when security is built-in, software updates are often needed to maintain a strong security posture, which is a challenge when there are millions of devices already deployed out in the field. Through an expanded integration with IBM Watson IoT Platform, its users can now manage, provision and update firmware over-the-air for their IoT devices through Mbed Cloud.

by Gary Mintchell | Mar 16, 2018 | Automation, Operations Management

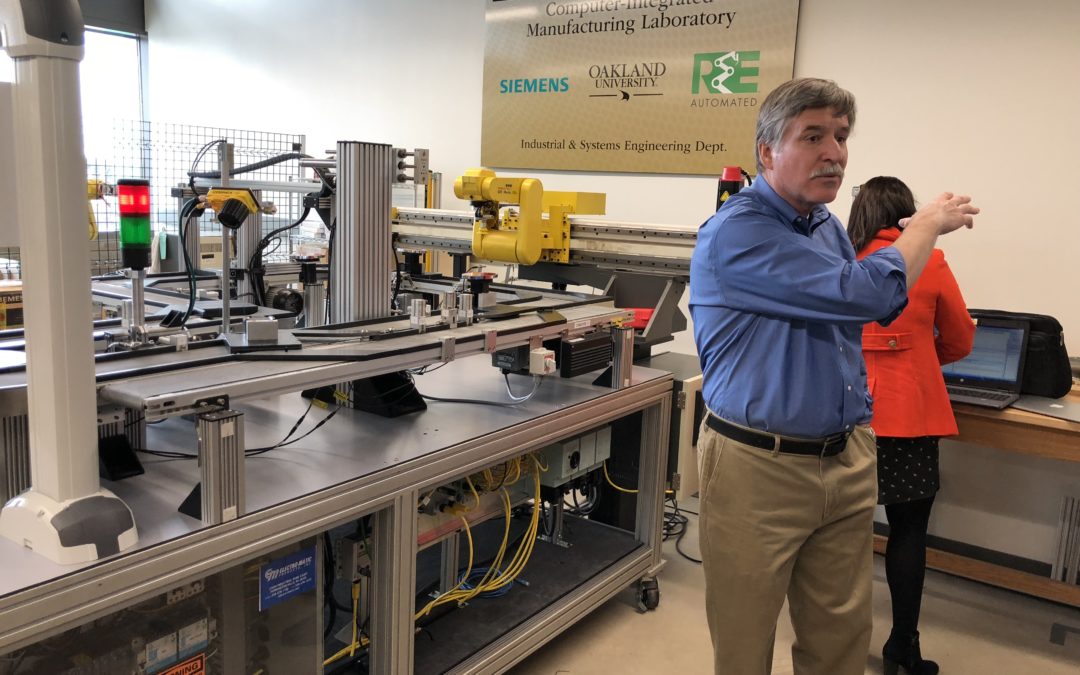

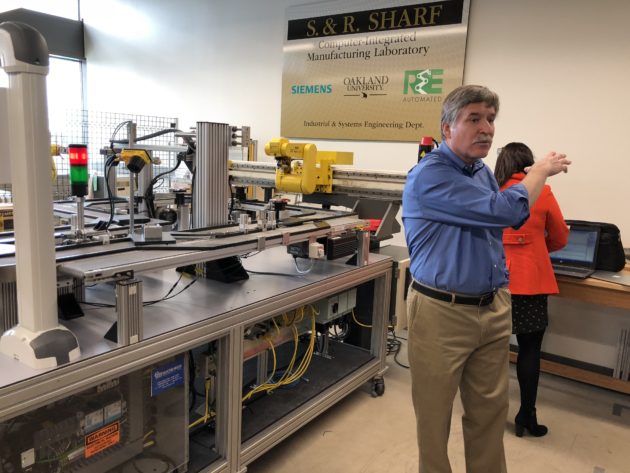

A small group of journalists and writers trekked to the Detroit area March 12-13 to glimpse the future of Manufacturing in America sponsored by Siemens Industry and its local distributor/partner Electro-Matic. We toured the local Founders Brewery facility, visited with faculty and students of Industrial and Systems Engineering at Oakland University, and attended the annual thought leadership panel.

Food and Beverage

Founders Brewery, craft brewery founded in Grand Rapids, MI, built a smaller version of brewery/restaurant in downtown Detroit not far from Ford Field and Greektown. The automated part of the brewery and instrumentation was supplied by Siemens. We toured the brewery, had an awesome sandwich, and sampled some of the many craft beers from founders.

Education

A complete change of pace (well, maybe not as I remember my college days) took us north to Rochester, MI to Oakland University. Robert Van Til, Ph.D., Pawley Professor of Lean Studies and Chair of Industrial and Systems Engineering (ISE), introduced us to his program and several students who explained their experiences both in class and working in local factories.

A complete change of pace (well, maybe not as I remember my college days) took us north to Rochester, MI to Oakland University. Robert Van Til, Ph.D., Pawley Professor of Lean Studies and Chair of Industrial and Systems Engineering (ISE), introduced us to his program and several students who explained their experiences both in class and working in local factories.

Siemens has donated much software and equipment to the program. Students explained how they had been trained in Siemens PLM software and used the simulation application to model real-world problems. They impressed me with a maturity I doubt that I had at that age, but also with how smoothly they integrated Lean Manufacturing concepts with their factory cell simulations.

-> An important point. I hold the impression left over from some years ago that young people view manufacturing negatively—as dark, dirty, unsafe, backwards places to work. Much to the contrary, these students all viewed manufacturing as a place to use their technical training to make an impact. They see how they can contribute to an organization immediately. I guess the work we’ve done over the past 20 years to clean up our factories and apply technology are being rewarded.

Finance 4.0

Nothing beats an early morning meeting to talk finance. Actually, it’s not that bad. Before the Wednesday summit meeting, we met with the Siemens Finance team. Note: we did this last year, as well.

Siemens has identified six challenges for manufacturers on the journey to Industry 4.0. Challenge No. 2 identifies access to finance for the scale of investment over time that manufacturers need to make in digital and automated technology platforms.

The team has released a white paper, “Practical Pathways to Industry 4.0 in the USA.” This would be Finance 4.0 for Industry 4.0. Snipping one section, “Integrated Strategic Finance,” here are a few points:

- Evaluate potential sources of finance for both OPEX and CAPEX

- Consider how you’ll finance all aspects of digital transformation

- Align with strategic growth vision and technology investment

- Find financing partners with willingness and skills for this journey

- Is your CFO a ‘virtuoso’ in linking initiatives to financial outcomes

Siemens Finance has many financial instruments in place to help from brownfield upgrades to greenfield projects—and for complete equipment financing, not only Siemens equipment.

Thought Leadership Summit

Raj Batra, President of Digital Factory for Siemens Industry Inc., took the ball from MC Eddie Murray (former NFL kicker), discussing how manufacturing executives in the US are very optimistic about the near future for manufacturing. One large problem is finding talented people to fill the positions. He also discussed Siemens technology and how it is helping manufacturers, for example like adidas who in this “order the latest fashion online” world need to shrink the 18 month timeline from concept to delivery of new shoes. Siemens PLM to the rescue.

Greg LaMay, Director Global. PLM Implementation for KUKA NA, showed how his team is using Siemens PLM applications to break silos within the company to improve time to ship and customer experiences.

John Greaves, IoT, RF, and Blockchain Solutions Architect (with a portfolio like that, he could probably bring the world to an end 😉 ) at Lowry Solutions, showed how Blockchain (the technology used by Bitcoin, for example) is already used for critical supply chain applications.

Alan Beaulieau, Ph.D., Economist, and President of ITR Economics (check it out, he wrote a column for me at Automation World for several years and he’s a great speaker), gave his usual well researched and reasoned view of the economic scene. Hint: it’s better than you might think reading the newspapers or listening to TV. itreconomics.com

by Gary Mintchell | Jan 19, 2018 | News

Industrial conferences and forums winter/spring season pops up with baseball’s spring training. I’ve written a couple of times about places I’ll be in February and March. Then a friend sent a note on LinkedIn—Gary, here’s a new conference you should attend.

Another friend started to tell me about it last week, but the conversation was diverted. So, I looked it up, contacted the organizer, and now I’ll be in Chicago January 31 and February 1.

The organizers are apparently European. The subject is Industry 4.0. That is the German initiative that is called in other places Industrial Internet of Things. Unveiling the Industry 4.0 Think Tank.

Some of the sponsors include Optel, Beckhoff, SMC, SME, and OPC Foundation. The speakers include a mix of suppliers and end users. And the list so far is impressive.

Quoting the event organizers, “The Industry 4.0 ThinkTank event brings together provocative thinkers, industry leaders and experts in various fields to get organizations ready for the next industrial revolution.”

Not only are there good speakers, but also the planners expect much networking to happen as well as informal discussions as they say, “Get ready to face global markets, become a leader in digital evolution, find strategic partners, mentors or competitors and learn from their real-life experiences. Discuss with industry specialists better ways to optimize the transition towards the next generation of manufacturing.”

A few bullet points of things you could expect:

- Uncover the Secrets to a Successful Industry 4.0. Transition

- Obtain a comprehensive understanding of your organization by analyzing your processes, human resources and information, as well as tools, control measures and culture.

- Discover ways to identify which systems/processes you may need to integrate into future solutions, and identify the analyses, assessments and listings needed to achieve that goal.

- Learn how to simplify and humanize the Industry 4.0 digitization of your business, along with industry peers facing the same challenges.

- Determine how to properly assess your employees’ strengths, weaknesses, potential and involvement to integrate Industry 4.0 requirements into your operations.

- Learn where we are headed industrialization-wise and analyze the maturity and ability of your company to withstand the revolution that is Industry 4.0.

- Explore automatization, employee mobility, business intelligence, efficiency, robotizing, process evolution and become more efficient in your day-to-day tasks.

- Grasp the complexities of Industry 4.0, learn tips on how to streamline your implementation and discover new technologies.

- Review principles that can be applied to your work and process in order to be more productive and up-to-date.

See you there!

by Gary Mintchell | Nov 8, 2017 | Interoperability, Operations Management, Software, Standards

Iconics has been a long-time supporter of OPC Foundation and an early adopter of OPC UA. President Russ Agrusa has seen the power and benefits of OPC as an information model for open interchange of data among industrial automation devices.

Thomas Burke, president of the OPC Foundation presented a keynote on the technology and benefits of OPC UA and the status of working with a variety of protocols such as Time Sensitive Networking, MQTT, AMQP, and others. I have written a white paper on TSN and OPC that you can download here.

The company provides advanced web-enabled OPC UA certified visualization, analytics, and mobile software solutions for any energy, manufacturing, industrial or building automation application. OPC is obviously a popular topic with Iconics developers as revealed by the packed session and probing questions.

“Connected Intelligence is our theme at this year’s customer summit and it all about connectivity to every “thing” in the Industrial Internet of Things (IIoT), which is critical for today’s manufacturing, industrial, and building automation systems. The OPC Unified Architecture (OPC UA) is the core standard for Industry 4.0 and IIoT. ICONICS works closely with the OPC Foundation and its technical committees to help create new standards that have applications in many industries.

“As a member of the OPC Board of Directors, I am proud to promote its many specifications and wide-reaching standards for manufacturing, industrial, and building automation,” says Russ Agrusa, President and CEO of ICONICS.

“I have presented at many ICONICS Worldwide Customer Summits over the years and I find meeting the wide variety of ICONICS customers, partners, and integrators from around the world to be rewarding. ICONICS early support and extensive commitment to OPC for over 20 years has helped propel OPC to where it is today,” says Thomas Burke, President of the OPC Foundation.

The ICONICS community of partners, system integrators and customers will learn from top industry experts how the OPC Foundation is driving the next wave of solutions for Industry 4.0 and the Industrial Internet of Things.

Takeaway: OPC UA has been recognized as an essential standard by Industie 4.0 in Germany and is a central technology for industrial data communication for software applications such as Iconics.

by Gary Mintchell | Sep 15, 2017 | News, Operations Management, Software

Whether it is the Industrial Internet of Things or Industry 4.0 or Smart Manufacturing no benefits are garnered at the end without a superb analytics engine. Recently I talked with Humera Malik, CEO of Canvass Analytics, about a new analytics company and product that brings Artificial Intelligence (AI) and Machine Learning (ML) to the field.

Early in my management career we called accounting “ancient historians” because reports only came out 10 days following a month end. That is too late to be what we call these days “actionable information.”

Turns out that a similar problem has existed in the predictive analytics field. OSIsoft and others have provided tools to capture huge amounts of industrial and manufacturing data. To get anything out of it you needed to establish a project, bring in a bunch of data scientists, and try to glean some trends or fit some models.

What was needed was a powerful engine that can use this data closer to real time, fit it into a model (selecting one from among several), and give operators, maintenance technicians, engineers, and others information in a useable time frame without bringing in a bunch of data scientists. These data scientists it turns out need to reside in the software. The entire process must be transparent to the user.

Enter Canvass Analytics, a provider of AI-enabled predictive analytics for Industrial IoT, which just announced a partnership with OSIsoft, a global leader in operational intelligence, that will enable Industrial companies to accelerate the return on investment of their IoT initiatives.

Malik commented, “Predictive and automated analytics gives operations teams the insights to answer questions such as, how can I increase yield, how can I reduce downtime and how can I reduce my maintenance costs? Canvass’ AI-enabled analytics platform accelerates the delivery of predictive insights by automating data analysis and leveraging machine learning technologies to adapt to data changes in real-time. For operations teams, this means they have the latest intelligence in order to make critical operational decisions.”

The combination of OSIsoft’s methodology to collect, store and stream data from any Industrial IoT source with Canvass’ AI-enabled automated analytics platform brings a new approach to creating predictive models that continually retrain themselves. With the resulting insight, Industrial companies have the potential to reduce plant maintenance by up to 50 percent and optimize plant operations by 30 percent.

“We are enthusiastic about the value that we see companies like Canvass Analytics extracting from the vast amounts of IIoT and other streaming data that we collect in our role as the single source of the truth,” said J. Patrick Kennedy, founder and CEO of OSIsoft.

A complete change of pace (well, maybe not as I remember my college days) took us north to Rochester, MI to

A complete change of pace (well, maybe not as I remember my college days) took us north to Rochester, MI to