by Gary Mintchell | Nov 22, 2016 | Automation, Manufacturing IT, Networking, News, Technology

Last week was GE Digital’s Minds + Machines Conference in San Francisco. This Industrial Internet (or Internet of Things to the rest of us) gathering showcases the latest of GE’s digital portfolio–including GE Automation and Control (the successor to GE Intelligent Platforms, successor to GE Fanuc Automation, whew).

Jim Walsh

Rich Carpenter

I tried to arrange my schedule to make it out there, but there had been too many trips in Sept., Oct., and Nov. for my time and expense budget to make it. So, we had a conference call meeting with Jim Walsh, President and CEO of GE Automation & Controls, and Rich Carpenter, Product GM of Control Platforms also at GE Automation & Controls. We talked about the Industrial Internet, digitalization, and new products.

Included in my news below are additional news from the M+M event including acquisition and product news.

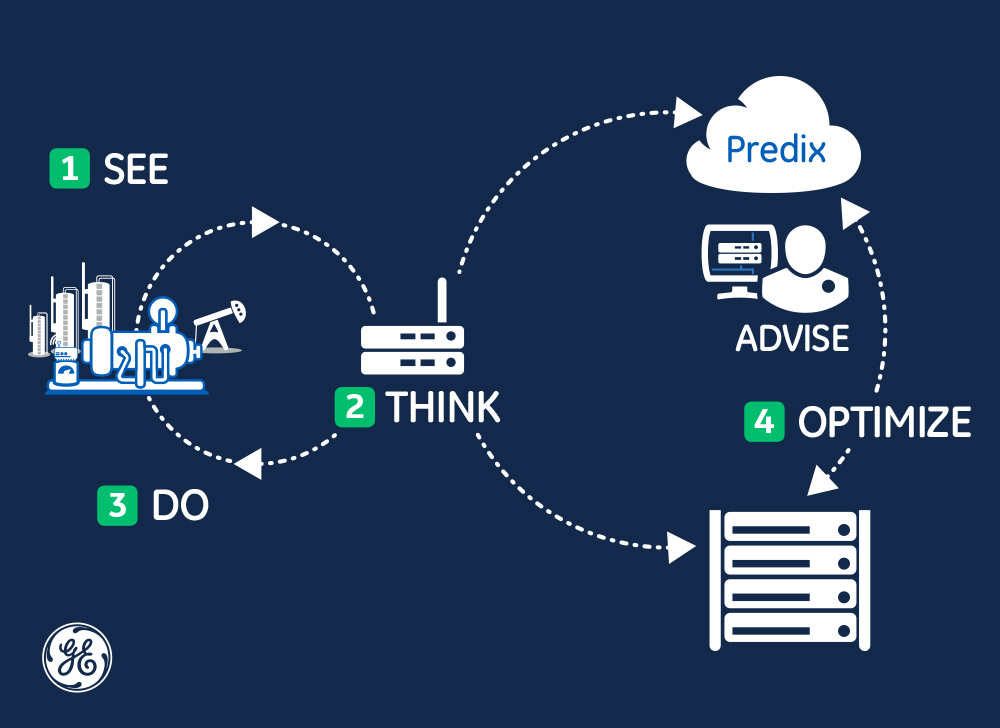

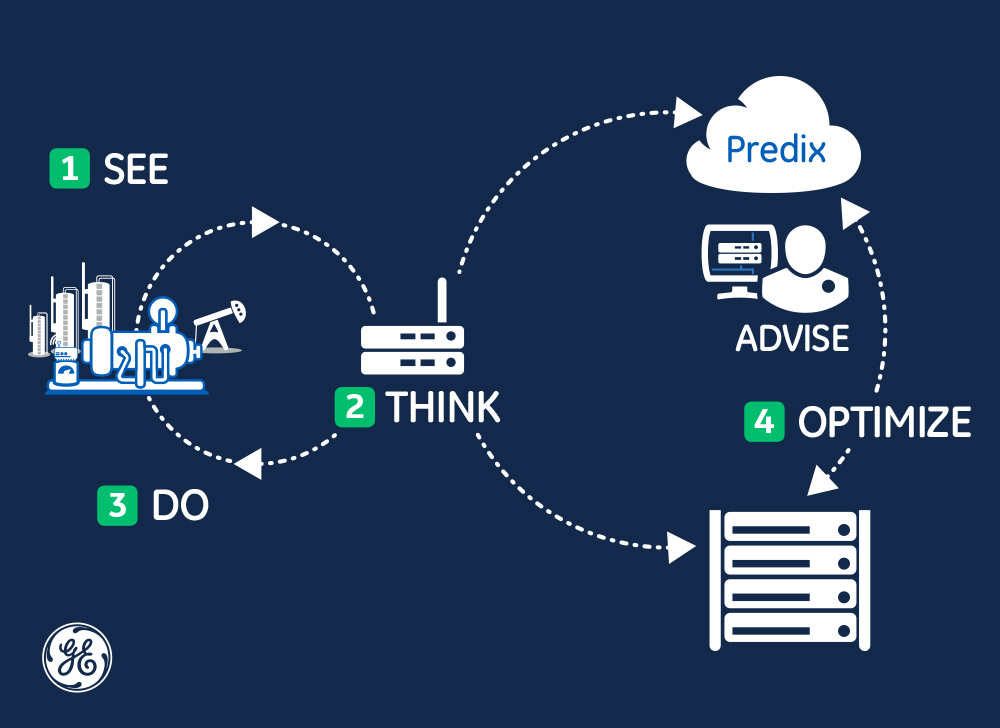

The point most interesting was Walsh and Carpenter discussed the edge device of the network as the controller (PLC). (See the graphic) Almost all of the other companies I talk with are developing an edge device separate from the controller. Carpenter described the closed loop control as “see-think-do”, and then the Industrial Internet plus Predix (GE’s cloud-enabled software product) analytics adds an “optimize” loop to the controller. It can then reflect back on experience and make changes as necessary.

Take for example large pumps in a water/wastewater application. They, of course, are energy consumers. By adding analytics from Predix, the controller could be modified to operate in a more energy efficient manner. One example proved out a $1.5 million per year savings. Another benefit is productivity improvements which Walsh said they had witnessed personally. They referred to the Industrial Internet Control System (IICS), which I will discuss later [Note: much like my Automation Fair update, this one will be long, because there is so much.]

And now, on to the news.

- GE releases new suite of Predix applications and services; introduces the Predix System

- Acquisition of Bit Stew Systems enables efficient data ingestion for industrial applications

- Acquisition of Wise.io strengthens machine learning and data science capabilities for Predix and enables enhanced Digital Twin development

- Meridium acquisition places GE in the lead for Asset Performance Management app development; acquisition of ServiceMax positions GE to lead in service transformation

- Ecosystem expands with independent software vendor program to speed industrial application development; more than 19,000 developers now building on Predix

- Digital orders on track to exceed $7B, a growth of 25%+ in 2016

- Digital thread productivity exceeds $600 million and accelerating into 2017

In 2016, orders from GE’s portfolio of software solutions are on track to climb 25%+ to more than $7 billion. Demonstrating the strength of Predix within GE, digital thread productivity will exceed $600 million, accelerating into 2017.

“The opportunity for industry is now,” said Bill Ruh, Chief Digital Officer of GE and CEO, GE Digital. “The Industrial Internet is profoundly transforming how we operate and our ability to deliver greater productivity for GE and for our customers. Connected machines, coupled with deep machine learning, are more powerful than anything we have seen. These strategic investments in both the Predix platform and our partners continue to attract industrial companies and provide them with tools they need to embark on their own digital industrial transformations.”

EXTENDING PREDIX FROM THE EDGE TO THE CLOUD

GE unveiled a new suite of software and applications.

This release will focus on expanding the platform and scaling development of Digital Twins – virtual representations of physical assets that comprise the world’s industrial infrastructure – through Predix apps and toolkits.

This new set of components can run on a variety of operating systems, devices and form factors – from sensors and controllers to gateways, server appliances and the cloud – making Predix a distributed system for the Industrial Internet and a complete “edge-to-cloud” offering.

GE also launched new Predix-based solutions, designed to help customers harness the power of the Industrial Internet:

Current, designed to analyze and optimize energy use and operational efficiency use across lighting, HVAC and other systems.

Digital Substation, extends maintenance optimization to the electricity grid.

Health Cloud, Cloud-enabled patient outcomes are linking clinical feedback to transformative radiology pathways.

Predictive Corrosion Management, a new Asset Performance Management (APM) solution that provides continuous inspection data and cloud-based analytics of pipe conditions to help operators manage corrosion-related risk.

Digital Power Plant software for gas, steam and nuclear plants, which features new tools to help customers reduce unplanned downtime by up to 5%, reduce false positive alerts by up to 75%, and reduce operations and maintenance costs by up to 25%.

Digital Hydro Plant, a suite of apps combining both software and hardware solutions designed to support Hydro customers globally, helping them get the most out of assets over the lifetime of a plant.

ACQUISITIONS

GE Digital announced it has acquired Bit Stew Systems to bring its data intelligence capabilities to Predix and other industrial solutions. Bit Stew applies its machine learning and artificial intelligence (AI) capabilities to automate the process of data modeling, mapping and ingestion, accelerating time to value for customers, such as BC Hydro, Pacific Gas & Electric and Scottish & Southern Energy. This acquisition will help GE Digital provide a solution to organize large amounts of data through efficient data organization at the edge or at the source of the data – the asset.

GE Digital also acquired Wise.io, a leading machine learning and intelligent systems company. This acquisition will enable GE Digital to further accelerate development of advanced machine learning and data science offerings in the Predix platform. The Wise.io team deepens GE’s machine learning stack and will spearhead innovative solutions in GE’s vertical markets to develop its machine learning offerings.

GE also announced a program dedicated to independent software vendors (ISVs), aimed at spurring development of industrial solutions and extending the reach of the Predix platform. Through these partnerships, GE will share its industry expertise and allow partners to use Predix as the building block for new industrial applications to enhance various components of industrial operations – such as maintenance, content development and asset management.

Inaugural launch partners include: Box, Decisyon App Composer, Entercoms, Ericsson, Mobideo, Nurego, OAG Analytics, Pitney Bowes and Splunk. The addition of ISVs enhances the growing ranks of the GE Digital Alliance Program, which launched in February. The alliance program now boasts more than 270 partners around the world, including major enterprise players such as AT&T, EY, Intel, Microsoft and Tata Consultancy Services (TCS).

GE’s Industrial Internet Control System

GE’s Automation & Controls business introduced GE’s new Industrial Internet Control System (IICS) at its 2016 Connected Controls Symposium at the company’s Global Research Center in Niskayuna, NY. IICS delivers new levels of productivity for industrial assets and processes by integrating controls with Industrial Internet analytics – at scale yet modular and flexible for industrial settings worldwide.

Early IICS adopters report a +7% gain in asset performance and 22% increase in efficiency. By leveraging GE’s deep domain and controller expertise, the IICS solution empowers customers to improve operational efficiency, optimize production and unlock new revenue opportunities.

The system utilizes GE’s Field Agent technology as the gateway between the asset and the Industrial Internet. Field Agent provides a rugged, pre-configured solution for secure data collection and conveyance from the machine to fuel analytics that improve operations.

GE’s Industrial Internet Control System also includes:

- Industrial Cloud Platform – Provides real time process optimization and control; minimalizes disruption to deployed application; Creates new value over time without having to retrofit

- Secure Cloud Connectivity – Predix ready; Provides secure data collection; Enables advanced analytics; Form factors to meet the need

- Outcome Optimizing Controllers – Real-time control; Defense in-depth security; Decreases time to market; Helps reduce unplanned downtime and enhance system performance

- Mix & Match I/O – Remote, real-time diagnostics; Wide range of communication options; Modularity-simple scalability; Drives improved availability and simplified maintenance

- Professional Services – Real Time control; Security at its core; Decreases time to market; Helps reduce unplanned downtime and enhance system performance

- Intelligent Apps – Real Time Control; Security at its core; Decreases time to market; Helps reduce unplanned downtime and enhances system performance

IICS features dual or quad core configuration which provides safe and secure communication with either cloud-based or locally hosted algorithms and applications.

Two structural innovations make the new solution “future proof” for customers, who want hardware assets to be long-lived but remain optimally functioning.

- Industry-first Hypervisor control technology that separates operations from software so that the software can be upgraded without affecting the physical controller, allowing the hardware to stay in place and up to date.

- ComExpress processor technology that allows the processor to be updated as needed, again without replacing the controller. This is critical to support the growing computational power available from the Industrial Internet, including GE’s Digital Twin predictive model for optimizing assets with minimal interruption.

by Gary Mintchell | Nov 21, 2016 | Automation, Motion Control

This post regarding magnetic encoders is not my typical news. I met with the company at Automation Fair a couple of weeks ago. It’s the newest thing I’ve heard in encoders in a while. Thought I’d pass it along for all you servo engineers and business development managers out there.

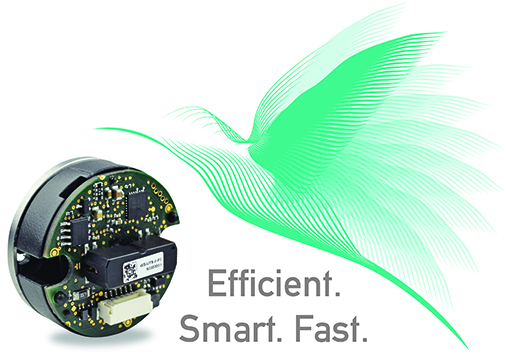

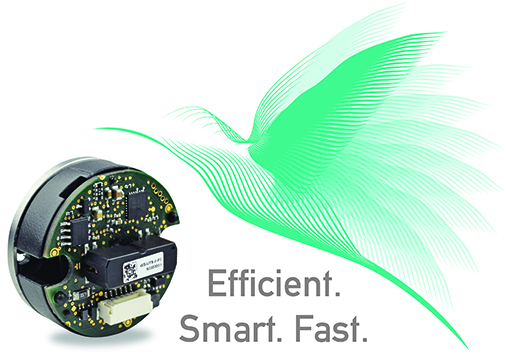

POSITAL’s new family of kit encoders provide the manufacturers of servomotors and other machinery with rugged, accurate and cost-efficient tools for building rotary position measurements into their products. The new kit encoders are based on POSITAL’s self-contained magnetic rotary encoders. Now however, the core components of these instruments are available as separate assemblies that can be readily integrated into other products.

POSITAL’s new family of kit encoders provide the manufacturers of servomotors and other machinery with rugged, accurate and cost-efficient tools for building rotary position measurements into their products. The new kit encoders are based on POSITAL’s self-contained magnetic rotary encoders. Now however, the core components of these instruments are available as separate assemblies that can be readily integrated into other products.

The POSITAL kit encoder components offer a number of advantages over the rotation measuring devices that have traditionally been used with servomotors and rotating equipment. Compared to resolvers, they are more accurate and offer multi-turn measurement capabilities. They also provide digital outputs instead of the analog signals produced by resolvers. While POSITAL’s magnetic encoder technology provides slightly less precision than the best optical disk encoders, it is less costly, less vulnerable to contamination from oil or dust and more resistant to shock and vibration. POSITAL encoders also provide an all-electronic multi-turn absolute position measuring capability that evaluates the full absolute angular position, including the total number of shaft rotations. The rotation counter is powered by the company’s well-proven Wiegand-effect energy harvesting technology so that rotation counts are always accurate, even if the rotations occur when external power is unavailable. This system eliminates the need for backup batteries or for the geared optical disks used in some products.

POSITAL magnetic kit encoders are easy to incorporate into normal manufacturing processes since they don’t require extra-precision, near-cleanroom assembly conditions. A built-in self-calibration capability can compensate for small sensor-to-shaft alignment errors. The electronic components, including Hall-effect sensors, a 32-bit microprocessor and the Wiegand-wire energy harvesting system, are packaged in a convenient 36 mm diameter, 24.2mm deep unit. For servomotors with magnetic brakes, a special magnetic shield has been developed to isolate the magnetic pickups of the measurement system from the external magnetic fields.

POSITAL magnetic kit encoders are easy to incorporate into normal manufacturing processes since they don’t require extra-precision, near-cleanroom assembly conditions. A built-in self-calibration capability can compensate for small sensor-to-shaft alignment errors. The electronic components, including Hall-effect sensors, a 32-bit microprocessor and the Wiegand-wire energy harvesting system, are packaged in a convenient 36 mm diameter, 24.2mm deep unit. For servomotors with magnetic brakes, a special magnetic shield has been developed to isolate the magnetic pickups of the measurement system from the external magnetic fields.

The resolution of the new POSITAL kit encoders is 17 bit, with an accuracy of better than + 0.1°. The operating temperature range is -40 to +105 °C. These devices are available with a variety of non-proprietary communications protocols, including BISS, SSI and RS485-based protocols.

POSITAL is a supplier of advanced industrial position sensors used in a wide variety of motion control and safety systems. The company is also an innovator in product design and manufacturing processes and a pioneer of Industry 4.0 (Industrial Internet of Things/IIoT), offering customers the benefits of built-to-order products combined with the price advantages of mass-production. POSITAL is a member of the international FRABA group, whose history dates back to 1918, when its predecessor, Franz Baumgartner elektrische Apparate GmbH, was established in Cologne, Germany to manufacture relays. Since then, the company has played a trendsetting role in the development of rotary encoders, inclinometers and other sensor products. POSITAL has a global reach with subsidiaries in Europe, North America and Asia – and sales and distribution partners around the world.

by Gary Mintchell | Nov 18, 2016 | Automation, Events, News

It is time to begin planning your trip to perhaps the only automation industry general gathering. Here is a teaser from ARC about its upcoming event.

Presenting the 21st Annual ARC Industry Forum Industry in Transition: Realizing the Digital Enterprise February 6-9, 2017 – Orlando, Florida. How will disruptive technologies change existing products and plants? How will open source solutions impact traditional software and automation domains? Is cybersecurity a threat to digitalization and, if so, how can the risk be mitigated? How ‘smart’ are smart machines, and what benefit will these bring? How do Big Data and predictive and prescriptive analytics enable operational change? How do connected products create opportunities in aftermarket services? What software capabilities are needed to achieve transformational change? Which industries are already changing? What steps can organizations take to foster innovative thinking? Join us at the 21st annual ARC Industry Forum in Orlando, Florida to learn more about how the digital enterprise will be realized and the benefits that this can bring. Discover what your peers are doing today and what steps they are taking in their respective journeys.

Presenting the 21st Annual ARC Industry Forum Industry in Transition: Realizing the Digital Enterprise February 6-9, 2017 – Orlando, Florida. How will disruptive technologies change existing products and plants? How will open source solutions impact traditional software and automation domains? Is cybersecurity a threat to digitalization and, if so, how can the risk be mitigated? How ‘smart’ are smart machines, and what benefit will these bring? How do Big Data and predictive and prescriptive analytics enable operational change? How do connected products create opportunities in aftermarket services? What software capabilities are needed to achieve transformational change? Which industries are already changing? What steps can organizations take to foster innovative thinking? Join us at the 21st annual ARC Industry Forum in Orlando, Florida to learn more about how the digital enterprise will be realized and the benefits that this can bring. Discover what your peers are doing today and what steps they are taking in their respective journeys.

I plan to attend for the 20th time. The only industry people not there are competitive analysts. There are representatives from most suppliers, foundations and associations, as well as from forward thinking end users. Most of the industry trade media will also be present. Suppliers began setting up press conferences several years ago. For a while it was quite a marathon where we would see a new presentation every half-hour for more than five hours! Then it was time for snacks and wine.

The sessions are usually interesting. ARC strives to have mostly users talking to users discouraging vendor sales pitches. One problem with that is that the vendors are the technology developers. If they would let their technology people speak, then that would really round things off. But marketing people being marketing people, they just can’t let an opportunity to be in front of prospects and customers go by without a pretty blatant sales pitch. So, ARC cuts that off in order to attract good discussions and quality attendees.

Start setting up appointments soon! Hope to see you there. Maybe we could organize a meet up.

by Gary Mintchell | Nov 18, 2016 | Automation, Networking, Standards

News regarding Time Sensitive Networking continues to flow. The University of New Hampshire InterOperability Laboratory (UNH-IOL), an independent provider of broad-based testing and standards conformance services for the networking industry, announced the launch of three industry-specific time sensitive networking (TSN) consortiums – Automotive Networking, Industrial Networking, and ProAV Networking – designed to provide deterministic performance within standard Ethernet for real-time, mission critical applications. By providing high quality test plans, tools, and test beds for TSN, UNH-IOL allows businesses to improve products and accelerate market readiness.

“Standards-based precise time, guaranteed bandwidth, and guaranteed worst-case latency in a converged Ethernet network is a game-changer to many industries,” said Bob Noseworthy, Chief Engineer, UNH-IOL. “Through UNH-IOL’s industry-specific TSN consortiums, companies can be at the forefront and drive the technology forward by validating their solutions with a full suite of testing services, which will allow applications such as self-driving cars and the Industrial Internet of Things (IIoT) to take off.”

Originally established as a “best effort” network, Ethernet needs additional specific features to deploy mission critical applications. TSN standards enable deterministic real-time communication over Ethernet, allowing solutions to be built to provide extremely precise, predictable timing across the network. By adding features to Ethernet such as time synchronization, ingress policing, seamless redundancy, frame preemption, scheduled traffic, and stream reservation, TSN ensures mission-critical, time sensitive data is not held up on the network, promoting an interoperable ecosystem spanning across many industries. As TSN standards mature, UNH-IOL consortium members are able to support rapid development of conformance and interoperability solutions for emerging standards, validating their silicon and early products by gaining access to test solutions as well as multi-vendor test beds.

A major driving force behind the development of TSN standards is the emerging Automotive Ethernet market. The future connected, autonomous vehicle requires the time sensitivity and predictability in networking that TSN provides to support Advanced Driver Assistance System (ADAS) requirements, infotainment expectations from consumers, and other elements of vehicle electronics. Supporting automotive original equipment manufacturers (OEMs) and manufacturers supplying OEMs enabled with deterministic Ethernet solutions, the TSN Automotive Networking Consortium provides a setting for collaboration and participation in shaping the emerging standards through neutral, third party conformance and interoperability testing.

TSN’s importance is also emerging in industrial automation due to the rise in interest around the IIoT, specifically the mission-critical, time sensitive data that must be transferred and shared within strict bounds of latency and reliability. TSN enhancements for Industrial Ethernet provide standards-based determinism and reliability needed for these applications. The TSN Industrial Networking Consortium brings together stakeholders to realize the benefits of TSN – bandwidth, security, interoperability, and latency and synchronization for IIoT, robotics, assembly plants, and machines, as well as shape the standards and protocols for TSN in the industrial market.

Recent enhancements and certifications in the audio/video market have created a wider choice of compatible products and open technology that brings high-quality AV networking within the reach of any size Professional AV system. TSN enhancements provide the important timing audio and video systems need. The Pro AV Networking TSN Consortium is a testing ground for the promises of seamless redundancy, low-latency, and synchronization in the professional audio/video market.

UNH-IOL provides the test facility for stakeholders across multiple industries – automotive, industrial, and Pro AV – to drive the emerging, maturing TSN standards. To learn more about joining the new consortiums, please visit: Automotive Networking TSN Consortium, Industrial Networking TSN Consortium, Pro AV Networking TSN Consortium.

by Gary Mintchell | Nov 17, 2016 | Automation, Networking, News, Organizations

Time-Sensitive Networking holds the promise for great advances in industrial networking when it gets adopted for deterministic high-speed Ethernet. The Industrial Internet Consortium (IIC) has taken a leading role in advancing the standard. Belden Inc. has joined the IIC Time-Sensitive Networking (TSN) Testbed, which aims to improve multi-vendor interoperability and to display the value of the IEEE 802.1 Ethernet standards for time-sensitive networking in a manufacturing ecosystem.

“By enabling a single Ethernet network to deliver time-guaranteed messages for both mission-critical and time-sensitive applications, while simultaneously delivering high-bandwidth, supervisory, data collection, video and other traffic, TSN fulfils a critical need in bringing the Industrial Internet of Things (IIoT) to manufacturing environments,” said Jeff Lund, senior director of product line management at Belden and co-chair of the IIC marketing working group. “Belden has been a leading participant in the IEEE standardization effort of TSN since 2009 and we’re excited to be at the point where that hard work is now demonstrated in a multi-vendor environment. We hope our many years of experience with TSN will add valuable insight to the testbed and ensure it delivers on its mission.”

The TSN Testbed was on display at the 2016 IoT Solutions World Congress in Barcelona, Spain, on Oct. 25-27. Event attendees viewed live demonstrations of the testbed, which includes Hirschmann’s prototype TSN-enabled RSP Ethernet switches, and see first-hand the possibilities TSN enables for industrial networks.

“The addition of Belden to our TSN Testbed will help bring our collective efforts one step closer to reality – as we all work together in the pursuit of converging IT and operational technologies,” said Dr. Richard Soley, executive director of the IIC. “Testbeds serve as a center of innovation, and we know Belden’s TSN experience will help us achieve our goal. This testbed in particular seeks to show the value of TSN technology, as well as identify and address any implementation challenges to continue improving the standards.”

Following the event, the testbed will be moved to National Instruments’ headquarters in Austin, Texas. In addition to National Instruments, Belden is working alongside leading industrial companies, including Schneider Electric and Bosch Rexroth, among others.

POSITAL’s

POSITAL’s POSITAL magnetic kit encoders are easy to incorporate into normal manufacturing processes since they don’t require extra-precision, near-cleanroom assembly conditions. A built-in self-calibration capability can compensate for small sensor-to-shaft alignment errors. The electronic components, including Hall-effect sensors, a 32-bit microprocessor and the Wiegand-wire energy harvesting system, are packaged in a convenient 36 mm diameter, 24.2mm deep unit. For servomotors with magnetic brakes, a special magnetic shield has been developed to isolate the magnetic pickups of the measurement system from the external magnetic fields.

POSITAL magnetic kit encoders are easy to incorporate into normal manufacturing processes since they don’t require extra-precision, near-cleanroom assembly conditions. A built-in self-calibration capability can compensate for small sensor-to-shaft alignment errors. The electronic components, including Hall-effect sensors, a 32-bit microprocessor and the Wiegand-wire energy harvesting system, are packaged in a convenient 36 mm diameter, 24.2mm deep unit. For servomotors with magnetic brakes, a special magnetic shield has been developed to isolate the magnetic pickups of the measurement system from the external magnetic fields.

Presenting the 21st Annual

Presenting the 21st Annual