by Gary Mintchell | Nov 18, 2016 | Automation, Networking, Standards

News regarding Time Sensitive Networking continues to flow. The University of New Hampshire InterOperability Laboratory (UNH-IOL), an independent provider of broad-based testing and standards conformance services for the networking industry, announced the launch of three industry-specific time sensitive networking (TSN) consortiums – Automotive Networking, Industrial Networking, and ProAV Networking – designed to provide deterministic performance within standard Ethernet for real-time, mission critical applications. By providing high quality test plans, tools, and test beds for TSN, UNH-IOL allows businesses to improve products and accelerate market readiness.

“Standards-based precise time, guaranteed bandwidth, and guaranteed worst-case latency in a converged Ethernet network is a game-changer to many industries,” said Bob Noseworthy, Chief Engineer, UNH-IOL. “Through UNH-IOL’s industry-specific TSN consortiums, companies can be at the forefront and drive the technology forward by validating their solutions with a full suite of testing services, which will allow applications such as self-driving cars and the Industrial Internet of Things (IIoT) to take off.”

Originally established as a “best effort” network, Ethernet needs additional specific features to deploy mission critical applications. TSN standards enable deterministic real-time communication over Ethernet, allowing solutions to be built to provide extremely precise, predictable timing across the network. By adding features to Ethernet such as time synchronization, ingress policing, seamless redundancy, frame preemption, scheduled traffic, and stream reservation, TSN ensures mission-critical, time sensitive data is not held up on the network, promoting an interoperable ecosystem spanning across many industries. As TSN standards mature, UNH-IOL consortium members are able to support rapid development of conformance and interoperability solutions for emerging standards, validating their silicon and early products by gaining access to test solutions as well as multi-vendor test beds.

A major driving force behind the development of TSN standards is the emerging Automotive Ethernet market. The future connected, autonomous vehicle requires the time sensitivity and predictability in networking that TSN provides to support Advanced Driver Assistance System (ADAS) requirements, infotainment expectations from consumers, and other elements of vehicle electronics. Supporting automotive original equipment manufacturers (OEMs) and manufacturers supplying OEMs enabled with deterministic Ethernet solutions, the TSN Automotive Networking Consortium provides a setting for collaboration and participation in shaping the emerging standards through neutral, third party conformance and interoperability testing.

TSN’s importance is also emerging in industrial automation due to the rise in interest around the IIoT, specifically the mission-critical, time sensitive data that must be transferred and shared within strict bounds of latency and reliability. TSN enhancements for Industrial Ethernet provide standards-based determinism and reliability needed for these applications. The TSN Industrial Networking Consortium brings together stakeholders to realize the benefits of TSN – bandwidth, security, interoperability, and latency and synchronization for IIoT, robotics, assembly plants, and machines, as well as shape the standards and protocols for TSN in the industrial market.

Recent enhancements and certifications in the audio/video market have created a wider choice of compatible products and open technology that brings high-quality AV networking within the reach of any size Professional AV system. TSN enhancements provide the important timing audio and video systems need. The Pro AV Networking TSN Consortium is a testing ground for the promises of seamless redundancy, low-latency, and synchronization in the professional audio/video market.

UNH-IOL provides the test facility for stakeholders across multiple industries – automotive, industrial, and Pro AV – to drive the emerging, maturing TSN standards. To learn more about joining the new consortiums, please visit: Automotive Networking TSN Consortium, Industrial Networking TSN Consortium, Pro AV Networking TSN Consortium.

by Gary Mintchell | Nov 15, 2016 | Automation, Data Management, Internet of Things, Operations Management

Kepware Technologies, a PTC business, announced the release of KEPServerEX Version 6 software for industrial automation data connectivity. A major release of its flagship industrial connectivity platform, Version 6 strengthens Kepware’s core product offering for global corporations requiring increased operational scalability, security, and support. Enhancements include a new method for remote configuration, additional languages that support critical industrial automation markets, and significant updates to the user interface and licensing experience.

“Since the launch of Version 5 in 2009, the need for industrial connectivity has grown tremendously. As the Internet of Things (IoT) continues to influence industrial architectures, companies require a comprehensive solution that can communicate and analyze a greater volume, variety, and velocity of data to a wider, more diverse set of client applications,” said John Harrington, Vice President of Product Management, Kepware. “We’ve incorporated important usability and architectural enhancements that support these evolving industry standards into KEPServerEX Version 6. Enterprise-ready, IT-friendly, and secure, Version 6 is a direct response to our customers’ expanding and evolving needs.”

KEPServerEX Version 6 features significant enhancements to the core server functionality and user experience that deliver an IoT-friendly industrial connectivity platform, including:

- Programmatic Changes via the Configuration API: The new REST-based API enables off-site users to remotely apply programmatic changes to the configuration via third-party client applications. Now customers can easily configure multiple KEPServerEX instances from their enterprise software, enabling improved security and collaboration between Operations and IT.

- Localization for Japanese and German Markets: Core features and top-tier drivers have been localized to improve the accessibility, productivity, and safety of KEPServerEX for local customers in Japan and Germany as well as global multinationals.

- Native Development of OPC UA Technology: Native development of core OPC UA technology provides improved performance, enhanced diagnostics, and a solid foundation for continued OPC UA functionality enhancements.

- Streamlined Licensing: Updates to KEPServerEX, the License Utility, and My Kepware improve the user experience and simplify license management—providing customers with more streamlined tools to deploy, manage, and update their servers.

- Improved User Interface (UI): An enhanced user interface streamlines project setup and deployment, enabling more effective and efficient interactions with KEPServerEX. The updates also promote a safe user experience, enable increased productivity, and improve accessibility.

- Robust Security: Now included as a complimentary core server component, the Security Policies advanced plug-in complements an industrial defense-in-depth strategy by enabling customers to assign security access permissions on individual objects based on user role.

“With the release of KEPServerEX Version 6, Kepware is able to provide a secure, truly enterprise-ready connectivity layer to the market,” said Tony Paine, Platform President, Kepware. “Our customers will benefit from an easy migration path that maximizes uptime—allowing them to meet productivity demands today while preparing for the requirements of tomorrow.”

KEPServerEX is an industrial connectivity platform that leverages OPC and IT-centric communication protocols to provide a single source of industrial automation data to enterprise applications. The platform offers a library of more than 150 device drivers, client drivers, and advanced plug-ins—enabling connectivity to thousands of devices and other data sources.

by Gary Mintchell | Nov 8, 2016 | Asset Performance Management, Internet of Things, Operations Management

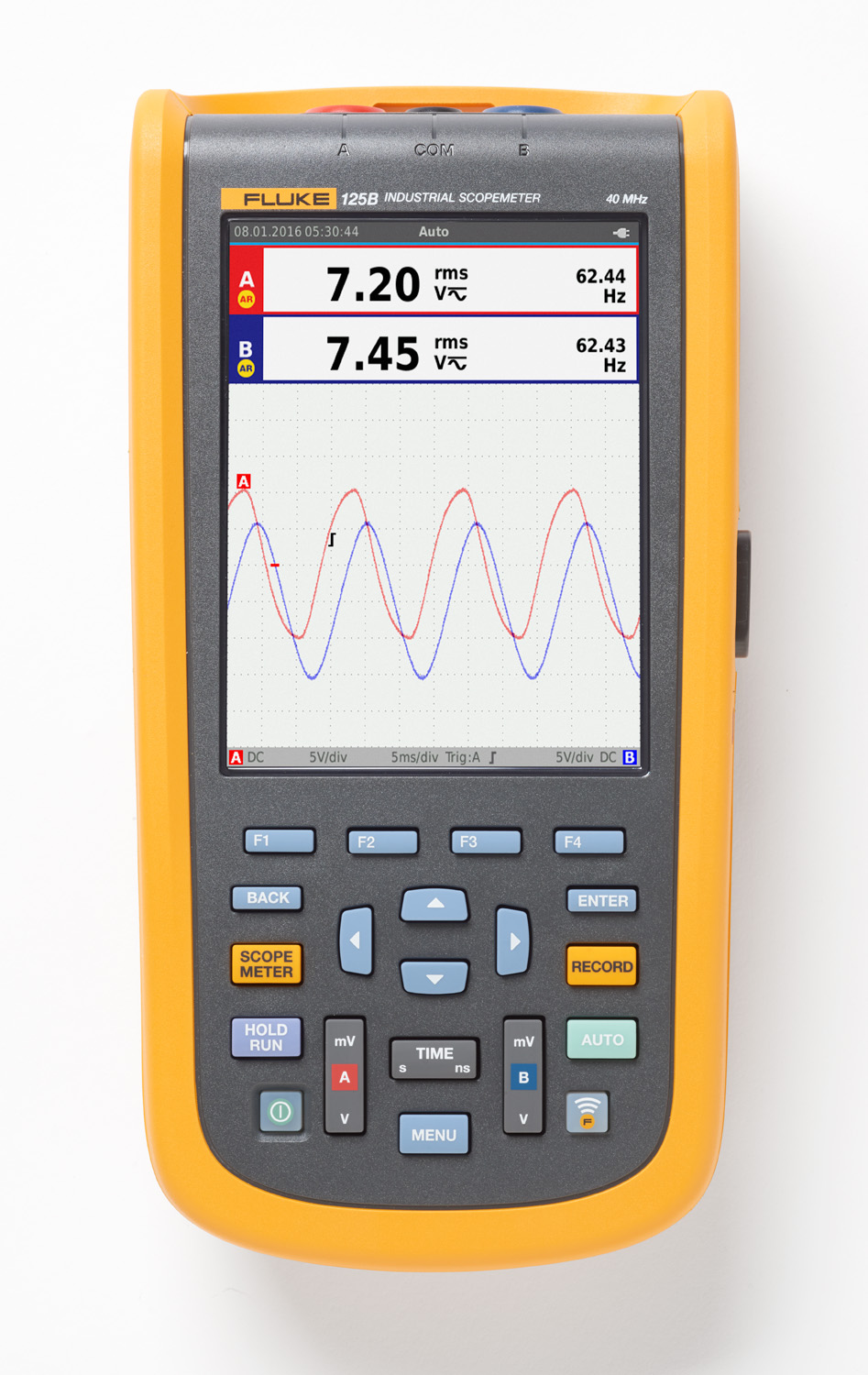

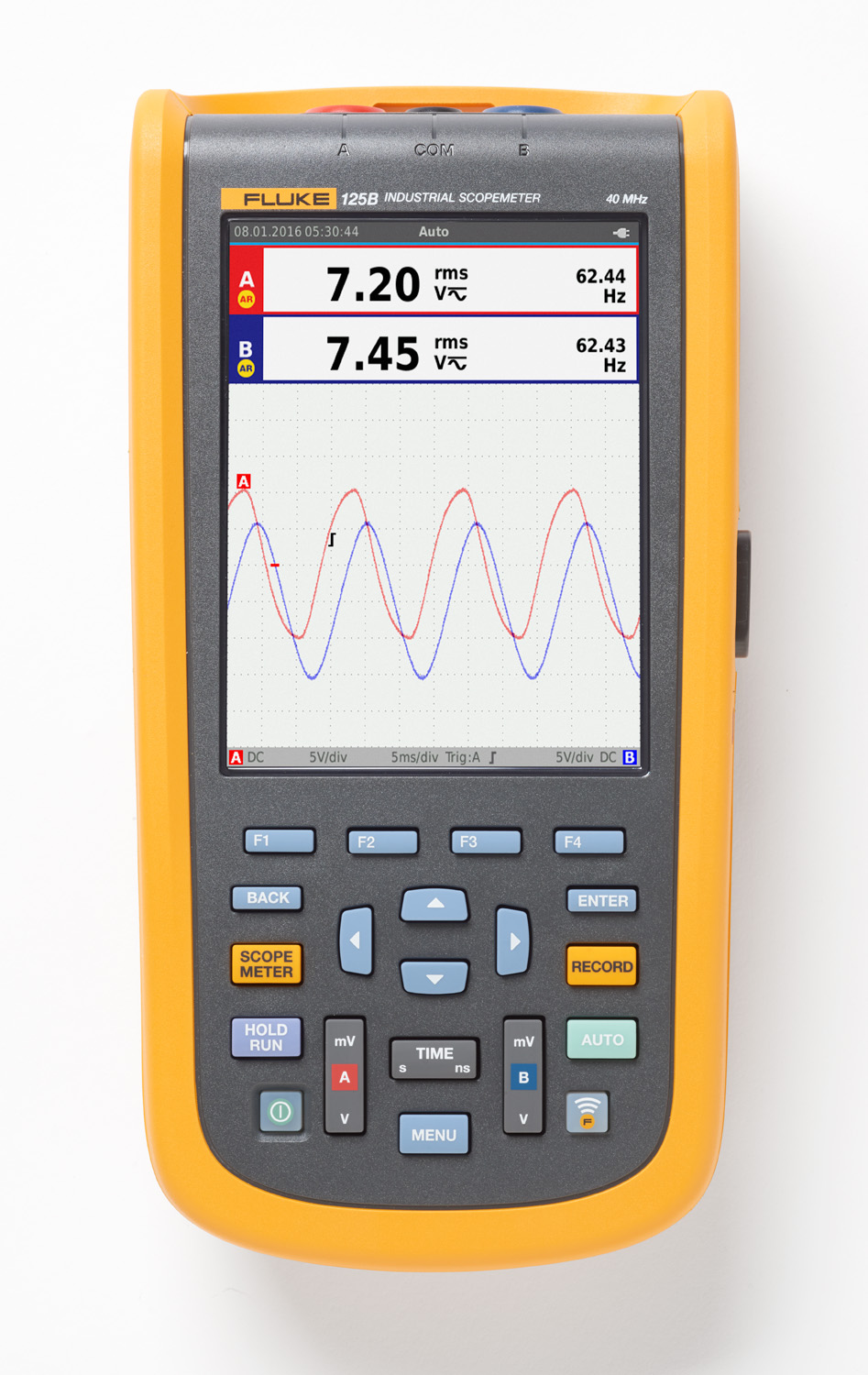

Fluke has drunk the Internet of Things kool-aid. It has taken a portfolio of measurement products and technology and connected them. I’ve followed it for a few years. It has recently announced an expansion of its cloud-based monitoring platform.

Fluke Connect reliability platform now offers cloud-based condition monitoring.

Monitoring plant equipment is crucial to avoiding costly downtime, but it is often too expensive, impractical, or complicated to capture performance data from all critical assets. The latest addition to the Fluke Connect reliability platform, Fluke Condition Monitoring, solves these problems with a new system of rugged voltage, current, temperature, and power sensors that can be moved from asset to asset or left in place for continuous monitoring. With Fluke Condition Monitoring, maintenance teams get a practical, scalable system that delivers the continuous data and alarms they need to prevent equipment downtime without costly equipment retrofits or specialized training.

“Adding Condition Monitoring to Fluke Connect revolutionizes maintenance workflows,” said Paul de la Port, President, Industrial Group, Fluke Corporation. “One system now manages the entire process — from equipment inspection and monitoring to setting alarm thresholds and assigning repairs. Certain types of plant equipment have fallen outside monitoring until now; the ROI just wasn’t there to retrofit with permanent sensors. The Fluke Condition Monitoring setup is so flexible and easy to install that technicians can put it wherever they need additional eyes on their equipment. And the new sensors funnel data into the same Fluke Connect reliability platform as all of our other connected test tools. With this system, technicians collect more data and engineers analyze more data in less time, with less work.”

Fluke Condition Monitoring consists of wireless sensors and a gateway that receives signals from the sensors from up to 30 feet away and works seamlessly with trusted, award-winning Fluke technologies, such as iFlex current probes, current clamps, temperature sensors and three-phase power monitoring.

Maintenance technicians can set the system up and begin monitoring in a matter of minutes, with the sensors transmitting measurements to the cloud as frequently as one measurement per second. Equipment data and alarm notifications are viewed through the Fluke Connect platform on a smartphone or web browser.

With this addition, the Fluke Connect reliability platform now compiles measurements from both the Fluke Condition Monitoring sensors and Fluke Connect wireless tools along with a history of work orders to create a comprehensive view of equipment health. The wireless, cloud-based solution overcomes legacy system silos and IT conflicts, works on any equipment type and helps teams stay effective while monitoring issues in different locations.

“The 3500 FC Series sensors operating with Fluke’s already well-established IIoT platform, Connect, create a strong value proposition for manufacturers, which seek to benefit from IIoT insights without a rip-and-replace greenfield buy,” said Christian Renaud, Research Director of 451 Research’s Internet of Things practice. “Products that are quick and easy to install and provide simple-to-determine ROI metrics should appeal to manufacturers.” 451 Research is focused on the business of enterprise IT innovation within emerging technology segments and provides timely insight to end user, service provider, vendor and investor organizations worldwide.

by Gary Mintchell | Nov 2, 2016 | Interoperability, News, Organizations

This is interoperability news day at The Manufacturing Connection with this announcement of an Internet of Things sensor-to-cloud testbed. This announcement also includes SAP (see other news today), along with TE Connectivity, ifm, and the OPC Foundation.

The objective of sensor-to-the-cloud connectivity is to make sensor data available to information technology (IT) systems in near real time, enabling advanced analytics. This is of particular interest to operators of existing manufacturing facilities, as it provides them with opportunities to increase efficiencies, e.g. through reductions in energy consumption.

This type of connectivity and use case has been forming for many years. All the pieces are coming together for a better application.

The Industrial Internet Consortium (IIC) has approved an IIC testbed on sensor-to-the-cloud connectivity called the “Smart Manufacturing Connectivity for Brownfield Sensors Testbed.” The testbed, led by IIC member TE Connectivity (TE), a world leader in connectivity and sensors, is being carried out with fellow IIC member SAP, the world leader in enterprise applications in terms of software and software-related service revenue, ifm, a worldwide leader in sensors, controllers and systems for automation, and the OPC Foundation, the foundation of the industrial interoperability standard OPC Unified Architecture (OPC UA). The idea for the testbed was publicly unveiled at the Hanover Fair in April of this year.

Unlike new deployments, where the appropriate connectivity may be designed in from the beginning, smart solutions are required for these “brownfield” installations in order to enable easy integration at both the operational technology (OT) and the IT level to reduce downtime and save costs.

The Smart Manufacturing Connectivity for Brownfield Sensors Testbed will:

- Introduce a retrofit hardware solution (the “Y-Gateway”) that makes use of existing physical connectivity

- Extract sensor data from the automation system without impacting operations

- Deliver the sensor data to SAP’s IT platform through a secure OT/IT communication based on OPC UA (IEC 62541)

- Define and implement a common device model based on an available open standard to allow for the easy integration of an IO-Link sensor with IT, enabling the remote configuration of the sensor

“Testbeds are a major focus and activity of the IIC and its members,” said IIC Executive Director, Dr. Richard Soley. “Our testbeds are where new technologies, applications, products, services and processes – the innovation and opportunities of the industrial Internet – can be initiated, thought through and rigorously tested to ascertain their usefulness and viability before coming to market.”

by Gary Mintchell | Oct 26, 2016 | Events, Internet of Things, News

The conference was all about digital transformation. Company leaders must begin thinking about digitally transforming their companies or they face disruption from digital startups.

This was Dell EMC World—the first user conference after the major acquisition of EMC by Dell forming Dell Technologies. Touting the size and breadth of the combined companies, Michael Dell began the meeting, “Let the transformation begin.”

A poll of business leaders returned these sobering thoughts:

- 45% may be out of business in 3 years;

- 48% 2-3 years see big changes;

- 78% digital startups will be a threat

As Jeff Immelt, CEO of GE put it, “You go to bed an industrial company and wake up a digital and analytics company.”

“Dell EMC will be the trusted provider of essential infrastructure for the next industrial revolution,” proclaimed Dell further into his keynote.

I attended the conference at the invitation of the Dell social influencer marketing group. Press conference attendance broke down as 41% analysts, 41% press, and 18% social influencers. They expect the press number to decline and influencer number to increase over time.

Michael Dell in press conference: “Internet of Everything helps customers embrace the digital future.” Dell also sees the need to help customers move from CapEx to OpEx. This need financial need from customers was echoed the next week at the Emerson Exchange. Companies in many industries at this time have slashed capital expenditures. Any movement forward in facility and process improvements must be done through operations expenditures.

This was my second Dell World. The Internet of Things group is just over a year old. Its unveiling was last year’s conference. This year’s presence was greatly enhanced. The booth layout simulated an ice cream factory (see diagram). Emerson Automation was represented (along with partners OSIsoft, Microsoft, and Dell) showing valves, wireless transmitters, date ported to a database into the Microsoft Azure cloud using a Dell IoT Gateway.

Emerson’s Jim Cahill wrote this section of the process in his Emerson Process Experts blog.

Dell has taken an embedded PC platform, added its services, mixed in a variety of partners and baked up an IoT solution. Other partners included Air Watch, Eigen Innovations, V5 Systems, IBM, KMC Controls, PTC Kepware, ELM Fieldsight. Solutions included quality, security, data communications, analytics.

As I have written several times over the past year, Dell is serious about the manufacturing space. The IoT platform is designed to leverage Dell’s vast IT contacts to achieve IT/OT convergence from the IT side.

Dell Technologies new products

Dell Technologies is a serious technology player on many fronts. I’ll just highlight some of the many announcements it made during the conference.

Michael Dell was insistent that integration of Dell and EMC was achieving rapid results. Many of the products announced resulted from just that integration.

From the press release:

Global business leaders agreed that moving toward a cloud model, expanding software development capabilities and enabling faster innovation and deeper insights from data are key strategies to digital transformation. However companies are struggling to evolve their data centers, with 69% saying they are being held back by too many traditional applications. They are challenged with reducing sprawl and spend, while bringing systems up-to-date. New products and solutions announced this week at Dell EMC World are designed to help organizations accelerate their transformation and manage costs.

“To ensure that they’re not “Uber’d”, “Airbnb’d” or “Tesla’d” in their marketplace, today’s organizations must embark on a digital transformation. To truly realize their digital future, we believe the vast majority of organizations will transform their IT through a hybrid cloud strategy, ” said David Goulden, president, Infrastructure Solutions Group, Dell EMC. “The first ‘no regrets’ step is to modernize their data center through the most advanced converged infrastructure, servers, storage, data protection, and cybersecurity technologies to name a few. This week we are launching a wave of new products and solutions designed as the building blocks for this endeavor.”

Announced this week at Dell EMC World:

- #1 Scale-Out NAS System Dell EMC Isilon Goes All-Flash For Unstructured Data

Dell EMC will announce a new member of the Isilon product family, combining the high performance of flash technology with the #1 scale-out NAS platform in the industry. Dell EMC Isilon All-Flash is designed to help IT organizations modernize their infrastructure and deliver on the capabilities of a digital business.

- Dell EMC Extends Common User Experience to SC Series

Dell EMC will announced it has boosted the capabilities of its mid-market proven SC Series (formerly Compellent) storage arrays by making it interoperable with the world’s leading portfolio of storage management, mobility and data protection solutions formerly only available to EMC customers.

- Extraordinary Dell EMC Partner Program To Provide Transformational Business Value and OpportunityDell EMC announced a preview of the company’s new and highly anticipated channel partner program. The Dell EMC Partner Program provides an unprecedented business opportunity for partners and validates Dell EMC’s commitment to the channel. Built on three core tenets—to be Simple, Predictable, and Profitable—the new program strategy ensures partners have ample opportunity, business continuity and commensurate profitability no matter their program tier.