by Gary Mintchell | Dec 4, 2014 | Automation, Motion Control

Technosoft, based in Neuchâtel, Switzerland, has released the first member of its iMOT line of motors with integrated motion controller and drive — the iMOT172S XM-CAN intelligent stepless motor.

based in Neuchâtel, Switzerland, has released the first member of its iMOT line of motors with integrated motion controller and drive — the iMOT172S XM-CAN intelligent stepless motor.

The product is based on a cost-effective hybrid step motor on which the motion control specialists at Technosoft have integrated a magnetic encoder, together with a member of their powerful iPOS motion controllers, into a very compact package (42 x 42 x 70 mm).

The design is made, for high reliability, with only one PCB incorporating the encoder and the iPOS controller that utilizes the Technosoft MotionChip technology and provides 7 I/Os. The configuration, tuning and local programming of the iPOS drive can easily be done using Technosoft’s powerful graphical platform, EasyMotion Studio. The position sensor is absolute single-turn, providing 4096 counts per revolution for accurate speed and position control, down to 5 arc minutes.

While an EtherCAT version is under preparation, the current release covers two CAN versions: the standard CANopen, in accordance to the CiA 301, 305 and 402 profiles, and the TMLCAN protocol. TML (Technosoft Motion Language) opens the possibility to use the powerful motion controller, allowing it to operate as an independent intelligent device. As an example, any homing routine can be customized to match the application needs. Standalone single- or multi-axis applications with communication between drives without the need of a CAN master are possible, while various types of CAN masters are as well supported through an extended set of Technosoft Motion Control Libraries.

This intelligent stepless motor reaches a peak torque of 500 mNm at 1000 rpm without a gearbox, achieved from a motor with a square flange of 42 mm. The maximum length of the integrated unit is a mere 70 mm. The high efficiency of the solution is obtained due to Technosoft’s implementation of current and torque vector regulation under a field oriented control method (FOC) that practically transforms the motor into a stepless servo motor, dramatically reducing the current consumption and heat dissipation typical to hybrid steppers.

The standard NEMA17 flange ensures multiple sources of gearheads that are available for fitting to the motor, depending on the requirements of the application.

An intelligent motor can be used in many applications, but it has been developed for medical analysis and dosing machines, pick and place and welding robots, instrumentation and optical equipment, unmanned military vehicles, packaging, bottling and labeling machines.

Intelligent Motion Control Drive

It has also rele ased the iPOS3604 HX-CAN—a closed frame intelligent drive offering a very compact solution for sinusoidal or trapezoidal position, speed and torque control of rotary or linear DC Brushless and open-loop or closed-loop control of 2-phase and 3-phase step motors requiring power up to 144 watts. The supply voltage range is 12 to 36 VDC with a continuous current of 4 A, (10 A peak) and a PWM frequency of 20 KHz.

ased the iPOS3604 HX-CAN—a closed frame intelligent drive offering a very compact solution for sinusoidal or trapezoidal position, speed and torque control of rotary or linear DC Brushless and open-loop or closed-loop control of 2-phase and 3-phase step motors requiring power up to 144 watts. The supply voltage range is 12 to 36 VDC with a continuous current of 4 A, (10 A peak) and a PWM frequency of 20 KHz.

This high performance servo drive offers high level single or multiple-axis control functions such as master, slave or standalone operations in a small package of only 80 x 55 x 16 mm. Although extremely compact, iPOS3604 HX embeds motion controller, drive and PLC functionality in one unit.

iPOS3604 HX can operate as a CiA402 CANopen drive, or can be programmed to execute complex motion programs directly at drive level, using their built-in motion controller and the high level Technosoft motion language (TML).Thanks to the TML instruction set, the iPOS3604 HX is an intelligent drive, programmable at user’s level and offering position and speed profiles, PVT & PT interpolated, electronic gearing and cam, external reference: analogue or sent via a communication bus.

The configuration, tuning and programming of the iPOS3604 HX-CAN drive is easy with Technosoft’s powerful graphical platform, EasyMotion Studio. System configuration and parameterization are performed by selecting and testing the system structure, motor and sensor types and control mode.

Flexibility and easy implementation make the iPOS3604 BX-CAN drives an ideal solution to fulfilling today’s motion axis control needs, using modern distributed intelligence architecture.

by Gary Mintchell | Nov 25, 2014 | Automation, Operations Management, Software

A couple of weeks ago I wrote about an Open Source SCADA project for Wonderware ArchestrA developers.

Recently Toby Dials wrote to me about a project he has started somewhat along the same lines. Here is his note to me.

I read your post in the Wonderware Experience LinkedIn group about the new aaOpenSource site that Andy and Eliot have put together. As these things usually happen, I had also been developing a site with a similar idea in mind – created in April of this year.

I worked for a Wonderware distributor for the last 17 years, and decided I wanted to focus on the SCADA products as a consultant, and part of that process led me to the creation of a website that would help make SCADA developer’s lives easier. The idea is that there are so many little things that were hard for me to remember, and I’d have to spend time looking them up over and over. Now, I can store them on one site so that others can use it as a reference site too. I’m slowly adding A2 objects and graphics as well – this is the part of my site this is most similar to their idea.

It isn’t a site for open source tools necessarily, but more so tips/tools/code/graphics for developers. Since my background is all Wonderware, that is the main focus of the site, but the structure is in place for adding content from experts with other software vendors.

This is all so cool. I haven’t heard much in the line of community development since the Linux PLC project on SourceForge sort of died a long, slow death. Good work, guys.

by Gary Mintchell | Nov 5, 2014 | Automation, Industrial Computers, Operator Interface

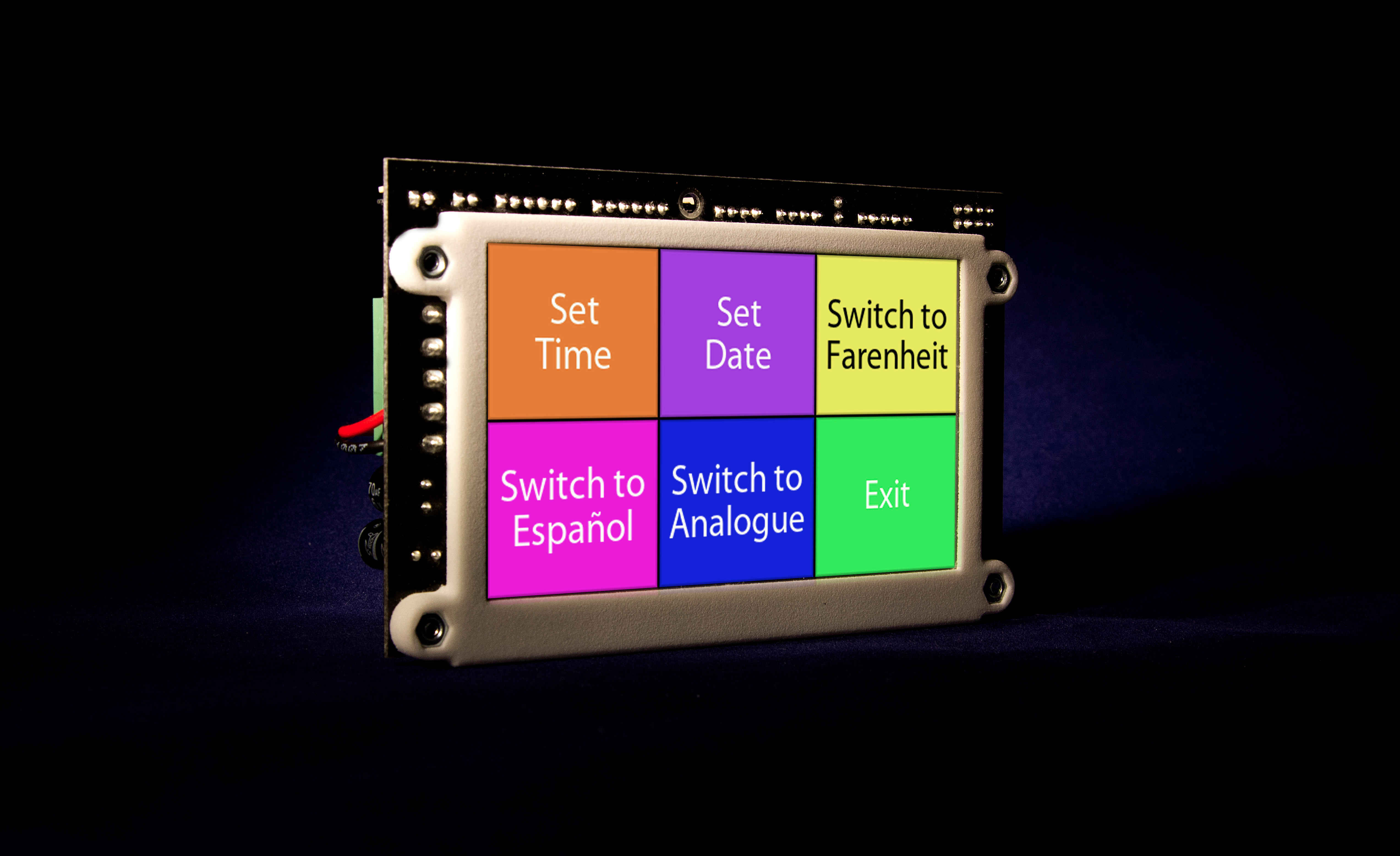

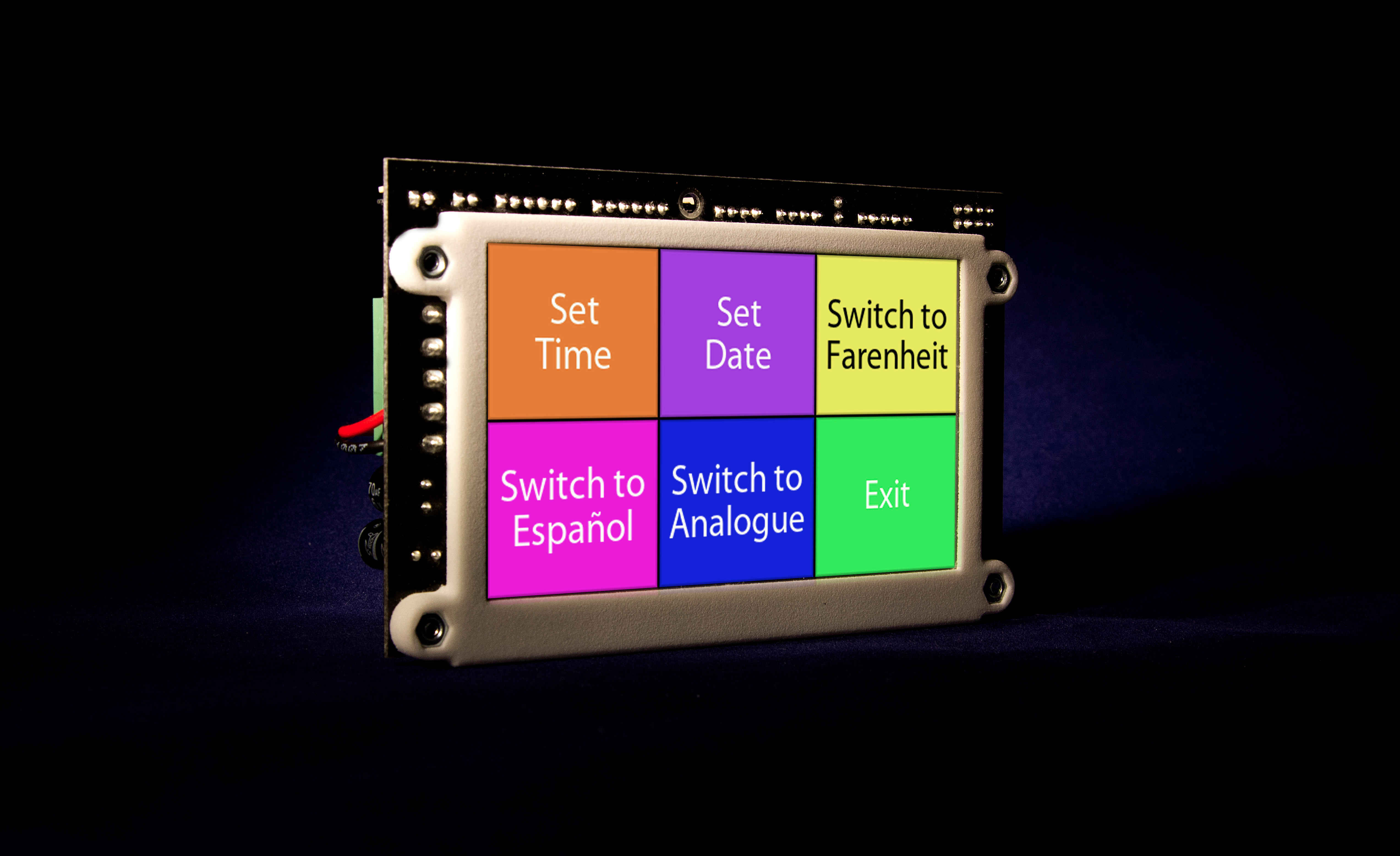

No doubt current trends in industrial controllers, programmable logic controllers (PLC) and human-machine interfaces (HMI) include driving down the cost of control. Here is one that is an integrated HMI/PLC for less than $400. Interestingly, this is the first product pitched to me in years that touts RS485 serial connectivity. I’d darn near forgotten all about those serial protocols.

No doubt current trends in industrial controllers, programmable logic controllers (PLC) and human-machine interfaces (HMI) include driving down the cost of control. Here is one that is an integrated HMI/PLC for less than $400. Interestingly, this is the first product pitched to me in years that touts RS485 serial connectivity. I’d darn near forgotten all about those serial protocols.

Anyway, here are some specifics from SPLat Controls.

The HMI430 board-level programmable logic controller (PLC) with an integrated 4.3-inch color touchscreen is available at nearly half the cost of previous products with similar functionality. With onboard, ruggedized digital I/O, analog I/O, and the SPLat MultiTrack built-in multitasking operating system, the HMI430 delivers “professional-quality control that is affordable and easy to program, minimizing development time.”

According to the press release, “With multiple serial ports HMI430 offers OEMs an ideal way to flexibly integrate a touchscreen into their solution for small- and medium-sized industrial control applications. The touchscreen—a 4.3-inch 470×272 pixel screen with resistive touch and 64K colors—comes with a repertoire of standard buttons, fonts, and other screen elements. With support for alpha blending, image files, and Z-ordering, HMI430 offers sophisticated visual effects at a price point that OEMs can afford.”

“With the advent of smartphones, all controller applications—medical, industrial, building control—are affected by the end-customers’ expectation of a GUI-driven interface,” noted David Stonier-Gibson, CEO of SPLat Controls. “The HMI430 with an integrated color touchscreen enables OEMs to respond to this ‘iEffect’ and provides the innovative edge that helps small- and medium-sized equipment manufacturers make their products smarter and more competitive.”

by Gary Mintchell | Jul 18, 2014 | Automation, Data Management, Operations Management, Technology

The most important news of the summer in manufacturing had nothing to do directly with manufacturing. Apple and IBM are collaborating. This is a significant evolution of cultures. In the beginning, Apple portrayed itself as the anti-IBM. Now, neither makes most of its money from personal computers.

IBM makes money from enterprise software and services. It’s database technology, competitive to Oracle, powers many large enterprises. It faces the same problems that Oracle and SAP face—the promises of enterprise-wide integration fall short of reality. Companies have invested heavily in the software and services to make it run. Yet, return on the investment has not lived up to expectations.

Apple makes most of its money from small devices. I view this as part of the fulfillment of Steve Jobs’ dream from the mid-80s of making computers easy enough for anyone to use. It’s just the the computers that embody that vision today do not sit on desktops. They slip into your pants pocket.

iPhones and iPads found their way into enterprise networks even faster than the rebels of the 80s who brought PCs into the factory. And with far less angst. Once technologies came together—radios, sensors, graphics power, designs, interfaces, cameras, software—the mobile device takeover of the enterprise happened before IT could figure out what was going on.

This means that every worker in a factory from manager to engineer to operator has more power in his or her pocket than the designers of the first rocket to the moon. Because manufacturing data now gets fed into corporate databases, people no longer need to search everywhere for information. Because everything is networked and all the networks interoperate, people, machines, devices and databases can all be connected with each other.

An operator has a problem with a machine? Just pull out the iPhone, call an engineer, show the engineer a video of the problem in real time, discuss the situation, arrive at a solution, enter a work order, log the situation, return to production. This is not only possible, it actually happens in forward thinking factories.

Several years ago, Ron Monday of Online Development and Fred Yentz of ILS Technology showed me how PLCs could be connected to IBM databases. We have far eclipsed that early vision. The next manufacturing revolution is happening while we watch.

by Gary Mintchell | Mar 12, 2014 | Automation, Data Management, Operations Management, Technology

Mitsubishi Electric Automation has been somewhat quietly building out a version of the connected manufacturing enterprise for several years. Known for machine control and motion control, it first made a splash by partnering with ILS Technology to develop e-F@ctory. This is connecting technology moving data from the control system to enterprise databases.

It recently announced an “e-F@ctory Alliance Program” that included several connectivity companies. It’s latest announcement is that eWON, which offers industrial VPN routers and Ethernet modems for remote access to PLCs and machines, is the newest member.

eWON devices allow original equipment manufacturers, systems integrators and end users to support their systems remotely. Consequently, eWON’s participation in the e-F@ctory Alliance Program gives Mitsubishi Electric’s customers greater options for anywhere, anytime access to their systems. eWON access options include remote HMI capability to monitor the machines using a built-in web server, data logging capabilities and alarming features.

As with all e-F@ctory Alliance Program products, Mitsubishi Electric has thoroughly tested the eWON solutions to ensure ease of implementation and compatibility with its own products. No programming of Mitsubishi Electric hardware is required to use eWON devices, other than setting the correct IP addresses.

“With the addition of eWON to our e-F@ctory Alliance Program, OEMs, systems integrators and end users can remotely access their systems across the globe,” said Robert Miller, senior manager, strategic collaborations and partnerships, Mitsubishi Electric Automation, Inc. “This eliminates the need for an engineer’s on-site presence to access a system, saving both time and money.”

Mitsubishi Electric’s e-F@ctory Alliance Program is a third-party referencing program with other automation hardware and software vendors that allows customers to select solutions that best solve their automation challenges. Through pre-engineered integration, the latest technologies are easier to use and more cost effective. Complete documentation, including quick start guides, sample programs and maintenance screens when required, are available for each solution, drastically reducing the time necessary to implement and maintain the solutions.

eWON joins third-party hardware and software vendors Balluff, COGNEX, LEM®, MDT Software, eWON, Kepware Technologies, Ocean Data Systems – Dream Report, CC-Link Partner Association and Powerit Solutions in the Mitsubishi Electric Automation e-F@ctory Alliance Program.

based in Neuchâtel, Switzerland, has released the first member of its iMOT line of motors with integrated motion controller and drive — the iMOT172S XM-CAN intelligent stepless motor.

based in Neuchâtel, Switzerland, has released the first member of its iMOT line of motors with integrated motion controller and drive — the iMOT172S XM-CAN intelligent stepless motor. ased the iPOS3604 HX-CAN—a closed frame intelligent drive offering a very compact solution for sinusoidal or trapezoidal position, speed and torque control of rotary or linear DC Brushless and open-loop or closed-loop control of 2-phase and 3-phase step motors requiring power up to 144 watts. The supply voltage range is 12 to 36 VDC with a continuous current of 4 A, (10 A peak) and a PWM frequency of 20 KHz.

ased the iPOS3604 HX-CAN—a closed frame intelligent drive offering a very compact solution for sinusoidal or trapezoidal position, speed and torque control of rotary or linear DC Brushless and open-loop or closed-loop control of 2-phase and 3-phase step motors requiring power up to 144 watts. The supply voltage range is 12 to 36 VDC with a continuous current of 4 A, (10 A peak) and a PWM frequency of 20 KHz.