by Gary Mintchell | Sep 17, 2019 | Automation, Technology

This entire area of collaborative robots (cobots) just keeps getting more interesting. The idea of humans and robots working collaboratively is intuitive but has been difficult to achieve. Cobots have ramifications far beyond industrial applications. But even here, they can lead the way to better productivity and effectiveness.

In this latest piece of news, Universal Robots (UR) announced the immediate availability of the UR16e which boasts an impressive 16 kg (35 lbs) payload capability.

This cobot combines the high payload with a reach of 900 mm and pose repeatability of +/- 0.05 mm making it ideal for automating tasks such as heavy-duty material handling, heavy-part handling, palletizing, and machine tending.

“In today’s uncertain economic climate manufacturers need to look at flexible solutions to stay competitive,” said Jürgen von Hollen, President of Universal Robots. “With UR16e, we meet the need for a collaborative robot that can tackle heavy-duty tasks reliably and efficiently. This launch significantly expands the versatility of our product portfolio and gives manufacturers even more ways to improve performance, overcome labor challenges, and grow their business.”

Developed on UR’s e-Series platform, the UR16e offers these benefits:

· Fast and frictionless deployment with easy programming and a small footprint

UR16e makes accelerating automation easy and fast. Programming and integration is simple – regardless of the user’s experience or knowledge base. Like all UR’s cobots, UR16e can be unpacked, mounted and programmed to perform a task within less than an hour. With a small footprint and 900 mm reach, UR16e easily integrates into any production environment without disruption.

· Addresses ergonomic challenges while lowering cost

With its 16 kg payload, UR16e eliminates the ergonomic and productivity challenges associated with lifting and moving heavy parts and products, lowering costs, and reducing downtime.

· Ideal for heavy-duty material handling and machine tending

Rugged and reliable, UR16e is ideal for automating high-payload and CNC machine tending applications, including multi-part handling, without compromising on precision.

“At Universal Robots we continue to push the boundaries of what’s possible with collaborative automation,” continued von Hollen. “Today, we’re making it easier than ever for every manufacturer to capitalize on the power of automation by bringing a cobot to market that is built to do more, as it delivers more payload than our other cobots.”

Like with UR’s other e-Series cobots; UR3e, UR5e and UR10e, the UR16e includes built-in force sensing, 17 configurable safety functions, including customizable stopping time and stopping distance, and an intuitive programming flow. UR16e meets the most demanding compliance regulations and safety standards for unobstructed human-robot collaboration, including EN ISO 13849-1, PLd, Category 3, and full EN ISO 10218-1.

by Gary Mintchell | Sep 3, 2019 | Operator Interface, Safety, Wireless, Workforce

I was working with controls, instrumentation, computers, software when I traded it in for media work first with Control Engineering and then with Automation World. Through a lot of those media years, Honeywell was one of the Big Four or Five in process control and systems. Over the past 6-10 years, those big companies have diverged into differing specialities. It’s been interesting to observe that part of the industrial market.

Honeywell began leveraging expertise of its various divisions into wireless, mobile, and wearables. Much of the emphasis has been safety with a spillover effect into productivity.

Wearables comprise a growing market category with much promise. I’ve had the opportunity to try on a number of different products. These increasingly solve real world problems with ever reducing interference in the real work of the person.

In this latest release, Honeywell announced that Braskem Idesa has adopted a hands-free, wearable connected technology solution at its plant in Veracruz, Mexico. Honeywell’s Intelligent Wearables will allow Braskem Idesa to improve productivity and compliance with process procedures, capture the expertise of experienced workers and provide critical insights and information effectively to trainees and support workers in the field.

Honeywell is delivering a complete outcome-based solution that tracks specific key performance indicators and integrates hardware, software and services, and a full Wi-Fi infrastructure to support use of the solution across the plant. The wearable technology will also accelerate training and ensure safety for field operators at the Braskem Idesa facility.

“With this solution, Braskem Idesa is embracing the digital transformation that will enable us to retain our leadership in the petrochemicals industry,” said Roberto Velasco Gutiérrez, industrial director, Braskem Idesa. “Capturing all the relevant expertise and data within the organization and getting it to workers wherever and whenever needed, will help get trainees safely into the field faster and ensure that every worker operates to Braskem Idesa’s best standards.”

A comprehensive range of applications from Honeywell will boost the speed, safety and reliability of field workers thanks to the following services:

- Expert on Call: Provides field workers with live, real-time access to experts in the central control room or elsewhere for troubleshooting, support and advice

- Video support: Enables users to view videos demonstrating key tasks

- Paperless rounds: Provides step-by-step instructions for common and complex tasks

“Braskem Idesa has not only taken an important step toward Industry 4.0 but has now also replaced paper-based and manual operations with a sophisticated solution that’s both digital and wireless,” said Vincent Higgins, director of technology and innovation, Honeywell Connected Enterprise, Industrial. “Wearable, voice-controlled computer headsets and software eliminate the need for clipboards, pens, and flashlights. Our offering will help Braskem Idesa capture expertise and document critical tasks to ensure operational compliance.”

Honeywell’s solution for field worker competency and productivity enables Braskem Idesa to tie its plant performance directly to the performance of its workers, critical to the success of any industrial enterprise. By connecting field workers with remote advice, Honeywell Intelligent Wearables also reduce the need for site visits from experts, empower workers to continue learning, become their best and effectively share their knowledge with peers.

by Gary Mintchell | Aug 26, 2019 | Automation, Technology, Workforce

I think even mainstream media has caught up to the current hiring situation—it is hard to find qualified people to fill positions. Heck, even last night stopping at a Cracker Barrel on the drive home from Tennessee we saw a harried staff and only about half the tables filled. They didn’t have enough people to staff the place.

Now try to find skilled welders. How about hiring a robotic welder? Easy to program and install. Always shows up for work. No drug test required. A very interesting idea.

The new for-hire BotX Welder—developed by Hirebotics and utilizing Universal Robots’ UR10e collaborative robot arm—lets manufacturers automate arc welding with no capital investment, handling even small batch runs not feasible for traditional automation.

The press release tells us, “Nowhere in manufacturing is the shortage of labor felt as urgently as in the welding sector, which is now facing an acute shortage of welders nationwide. The industry’s hiring challenge, combined with the struggle metal fabrication companies experience in producing quality parts quickly and in small runs, prompted Hirebotics to develop the BotX Welder.

“Many people didn’t believe that collaborative robots could perform such heavy-duty tasks as welding,” says Rob Goldiez, co-founder of Hirebotics. “We realized the need of a solution for small and medium sized metal fabricators trying to find welders.” Hirebotics’ hire-a-robot business model built on the Universal Robot, set the foundation for the BotX. It is a welding solution powered by the UR10e cobot that is easy to teach, producing automation quality with small batch part runs.

The BotX is now available to early access customers and will officially launch at FABTECH in Chicago, November 11-14.

In developing BotX, Hirebotics addressed two major hurdles of robotic welding: the ease of programming and the ease in which a customer can obtain the system without assuming the risk of ownership. There are no installation costs with BotX and with cloud monitoring, manufacturers pay only for the hours the system actually welds. “You can hire and fire BotX as your business needs dictate,” explains Goldiez.

The complete product offering comes with the UR10e cobot arm, cloud connector, welder, wire feeder, MIG welding gun, weld table, and configurable user-input touch buttons. The customer simply provides wire, gas, and parts. Customers can teach BotX the required welds simply via an intuitive app on any smartphone or tablet utilizing welding libraries created in world-class welding labs. A cloud connection enables 24/7 support by Hirebotics.

“We chose Universal Robots’ e-Series line for several reasons,” says Goldiez. “With Universal Robots’ open architecture, we were able to control, not only wire feed speed and voltage, but torch angle as well, which ensures a quality weld every time,” he says. “UR’s open platform also enabled us to develop a cloud-based software solution that allows us to ensure a customer is always running with the latest features at no charge,” explains the Hirebotics co-founder. “We can respond to a customer’s request for additional features within weeks and push those features out to the customer with no onsite visits,” says Goldiez, emphasizing the collaborative safety features of the UR cobots. “The fact that they’re collaborative and don’t require safety fencing like traditional industrial robots means a smaller foot print for the equivalent working space, or put another way; less floor space to produce same size part. In many cases less than half the floor space of traditional automation,” he says. “The collaborative nature of the solution enables an operator to move between multiple cells without interrupting production, greatly increasing the productivity of an employee.”

PMI LLC in Wisconsin, was one of the first customers of the BotX. “A large order would mean, we need to hire 10-15 welders to fulfill it – and they’re just not out there,” says VP of Operations at PMI, Erik Larson. “Therefore, we would No Bid contracts on a regular basis. With the BotX solution, we now quote that work and have been awarded contracts, so it has really helped grow our business,” says Larson. “The BotX Welder doesn’t require expensive, dedicated fixturing and robot experts on the scene.” Now PMI’s existing operators can handle the day-to-day control of the BotX, which welds a variety of smaller product runs.

The Wisconsin job shop has now stored weld programs for more than 50 different parts in their BotX app. “We are now able to deliver quality equivalent to what we could accomplish manufacturing with very expensive tooling typically used with higher-volume part runs,” says PMI’s VP of Operations, mentioning the ease of accessing the solution. “Being able to simply hire the BotX Welder, and quickly switch between welds by using our smart phone—and only pay for the hours it works—is huge for us. It took our area lead, who had no prior robotics experience, half an hour to teach it how to weld the first part.”

Another significant benefit was PMI’s ability to get the BotX welds certified for customers who require this. “This now means we do not need to use certified welders to oversee the operation. As long as the cobot welder’s program is certified, any operator can tend the cobot welder. This really unlocks a lot of resources for us,” says Larson. “Hirebotics and Universal Robots really hit the mark with this, we’re looking forward to a long partnership with them.”

by Gary Mintchell | Jul 31, 2019 | Asset Performance Management, Internet of Things, Productivity

Moving to sustainable sources of energy to generate electrical power, as Europe has, requires a balancing act. Solar and wind generation provide an imbalance of power since they only operate when proper atmospheric conditions exist—i.e. sunlight or wind. Hydro generation provides a necessary balance, explained Pier-Vittorio Rebba, technology manager power generation for ABB.

But many hydro plants are aging. Management realizes the need to digitalize operations to obtain the best use of Asset Performance Management applications as well as best optimization of plant assets. ABB and its customer Enel Green Power partnered to digitalize operations delivering predictive maintenance solutions that will lower maintenance costs and transform the performance, reliability, and energy efficiency of its hydropower plants throughout Italy.

The three-year contract will enable 33 of Enel Green Power’s hydroelectric plants, comprised of about 100 units, to move from hours-based maintenance to predictive and condition-based maintenance, leveraging the ABB Ability Asset Performance Management solution. With operations in five continents, the Enel Group’s renewable business line, Enel Green Power, is a global leader in the green energy sector, with a managed capacity of more than 43 GW.

“We are privileged to be partnering with Enel Green Power, a digital pioneer, in their move from hours-based to predictive maintenance utilizing ABB Ability technologies for big data, machine learning and advanced analytics,” said Kevin Kosisko, Managing Director, Energy Industries, ABB. “Predictive maintenance and asset performance management must become a key component of plant operators’ strategies to optimize maintenance operations, minimize risk, improve resilience and reduce costs. The results are more competitive electricity rates, in a more sustainable way.”

Collaborating closely since early 2018, the two companies have jointly developed and tested predictive maintenance and advanced solutions (PresAGHO) via a pilot on five Enel plants in Italy and Spain, including Presenzano, a 1,000-megawatt plant near Naples.

The new contract includes digital software solutions and services that will provide analysis of over 190,000 signals and the deployment of about 800 digital asset models, aimed at improving plant operational performance, reducing unplanned failures and enabling more efficient planned maintenance practices through predictive maintenance. The integration is expected to yield savings in fleet maintenance costs and increase plant productivity.

The ABB Ability Collaborative Operations Center for power generation and water will help bring wider benefits of digitalization and engagement, supporting informed decision-making, real-time solutions and cost savings. The center already provides similar digital solutions and advanced applications for more than 700 power plants, water facilities and electric vehicle charging stations globally.

“With personnel retirements resulting in knowledge gaps and more competitive electricity marketplaces, we believe that many power generation customers globally can benefit from this kind of digital transformation around maintenance and operations,” said Mr Kosisko.

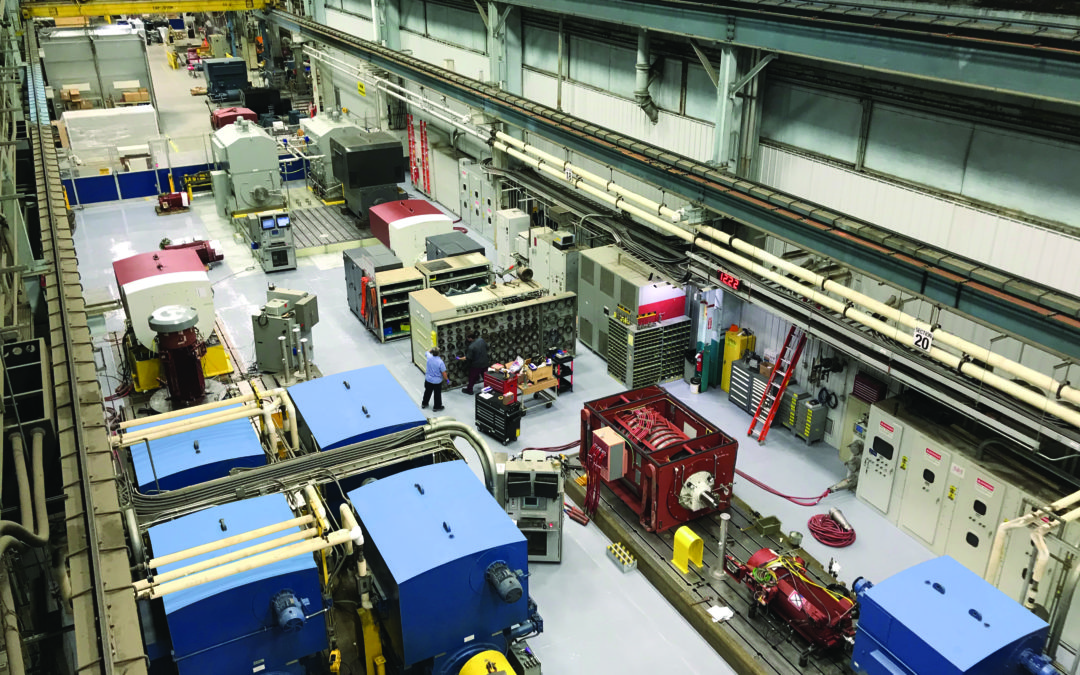

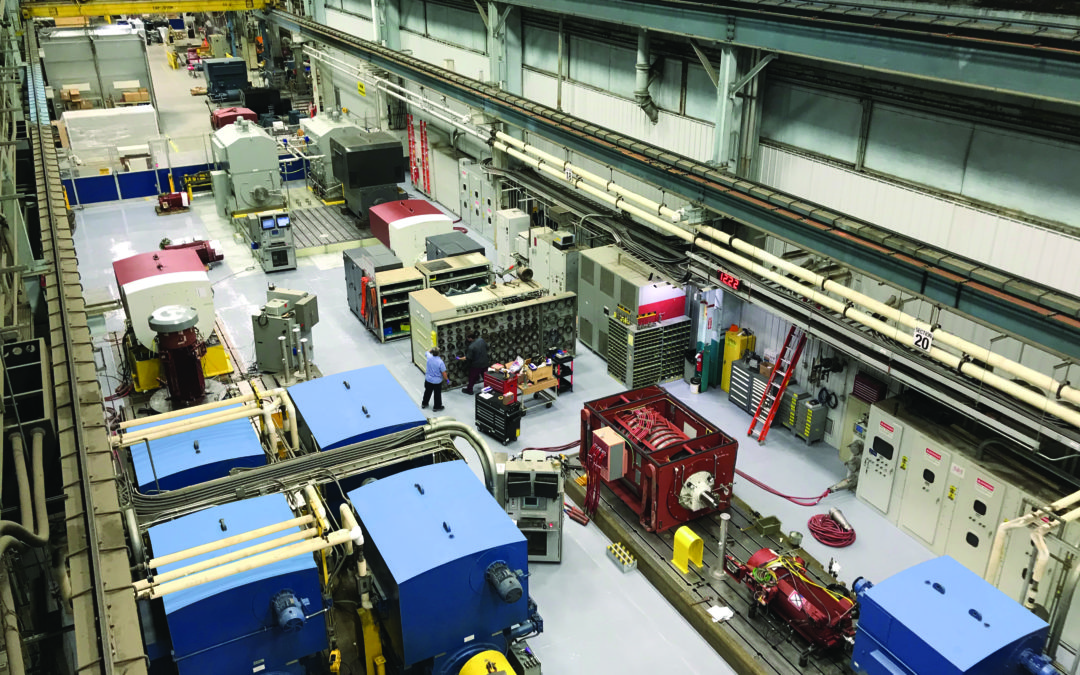

by Gary Mintchell | Jul 12, 2018 | Automation, News, Technology

There are electric motors and then there are electric motors. On my recent trip about an hour south to the Siemens electric motor manufacturing plant in Norwood, OH (a suburb of Cincinnati) I was often thinking about the line from Crocodile Dundee when the main character pulled out that child of a sword and Bowie knife and said, “Knife? That ain’t no knife. This is a knife.” When we start talking Medium Voltage motors at greater than 10,000 HP, that’s a motor.

Note: the one in red is a motor under test. Note the size versus the size of the person.

I’ve visited the plant a time or two before but wrote the news for magazines. Only a mention on my blog. When I was there in 2012, they talked about the transformation of the plant from a traditional old-school heavy manufacturing plant to a modern, lean, clean place to work putting out quality products.

The occasion for this visit was to view results of some significant investments by Siemens in maintaining Norwood as a state-of-the-art motor manufacturing plant. There are several new machines for precision machining of large parts. The pièce de résistance however was a new test bed and “Test Center Observatory” where customers can witness the testing of their motors in comfort with a dedicated Ethernet connection so that they can continue working during downtimes in the test process. A complete test regimen can last for several hours or even longer. Some customers come from other countries. Speaking as someone with experience traveling to witness tests on my products for certification, I’d have really appreciated this facility back in the day.

Before I get to the test bed, a brief discussion of digitalization and vibration.

Siemens has developed a digitalization methodology for motors called Drive Train Analytics. They are sensoring more and more in order to monitor and analyze a more complete virtual picture of the motor. Not surprisingly, they use Siemens Mindsphere sending data to the cloud using a variety of analysis tools. Customers have access to these tools in the observatory. Actually, customers could receive a complete virtual runoff of their motor back home. But engineers being engineers, they love to see the hardware in person. So they get both.

Aside from heat, the main killer of motors is vibration. Siemens has taken steps both to reduce vibration in the motor and to reduce ambient vibrations in the test process so that more accurate readings of the motor itself.

Working with customers who provide feedback from their use cases, Siemens developed a new shaft requiring new machining techniques. Some of the advantages of the new shaft include:

- Eliminates variation due to fabrication and spider bar tolerances

- Reduces required balance weight applied during rotor balance

- Removes heat-treatment process

- Improves rotor thermal stability

- More predictable rotor lateral stiffness

- Reduces stress concentration of weldment

The News-Test Observatory

With its celebration of more than 120 years of innovation, market and product leadership, technology and quality, Siemens’ Norwood Motor Manufacturing plant recently opened a new Test Observatory.

Opened in 1898, the Norwood facility has undergone a century of change, as the process to manufacture motors and the technology behind them has improved. Norwood has stood the test of time through three industrial revolutions and is one of the longest continuously operating Siemens’ plants globally. With Industry 4.0 upon us, the mechanical motor of old is now a connected device, a valuable plant floor asset capable of providing vast amounts of data with preventative and predictive analytics to ensure more productivity, efficiency and uptime.

With the largest motor test base in North America, Siemens can combine its century of industry leadership in motor manufacturing with an enhanced customer experience. The new equipment extends Norwood’s testing range from 10,000 horsepower (HP) to 20,000 HP at frequencies from 10 Hz to 300 Hz, thus addressing the market’s increased use of variable frequency drives. The new test observatory, akin to an executive suite, allows customers to participate by observing testing through bay windows, direct cameras and mirroring computers, which display real time critical data being gathered by sensors attached to their motor.

The project, which began in 2016, required the removal of 550 tons of soil and concrete from the site, excavating a 13-foot deep hole, driving 114 pilings for stability and building a huge concrete vault to securely support a fully loaded test stand. The test stand weighs 360 tons and rests on a self-leveling air spring system designed to support 500 tons when loaded with motors and drives.

The testing equipment includes two Sinamics Perfect Harmony GH180 drives and two dynamometers. Generating power to test a 20,000 HP motor requires significant amounts of electricity, and by recycling power to the grid, the new equipment reduces power loss by 90 percent.

“At Norwood, we test every motor that we produce or repair – some 30 to 50 tests per week – and these new facilities give us the ability to conduct as many as five motor tests at a time.” said Tim Bleidorn, Manager, Manufacturing Excellence. “We expect the customer witness tests to average two to three per week and as many as 120 per year.”

In addition to the new test base and observatory, the multi-million dollar investment in Norwood also includes WFL high-precision shaft making equipment and a high-speed balancer, key for two-pole applications at higher speeds and the ability to balance a rotor at up to 12,000 rpm.

“It’s exciting and I’m proud that Siemens is investing in the North American market. We have the No. 1 market share in AboveNEMA motors right now and these new capabilities send a strong signal to our customers and competitors that we intend to maintain that position,” says Ryan Maynus, AboveNEMA Product Manager.

With more than 100 patents, the 350,000 square-foot facility is a cornerstone to Siemens AboveNEMA motors. The ISO-9001 certified plant has produced more than 150,000 high voltage motors since 1898. The Norwood plant produces horizontal AC induction motors up to 20,000 horsepower and voltage ranges from 460 to 13,200 volts. The plant also manufactures a complete line of large AC vertical motors up to 8,000 horsepower.