by Gary Mintchell | Mar 22, 2016 | Automation, Internet of Things, Operations Management

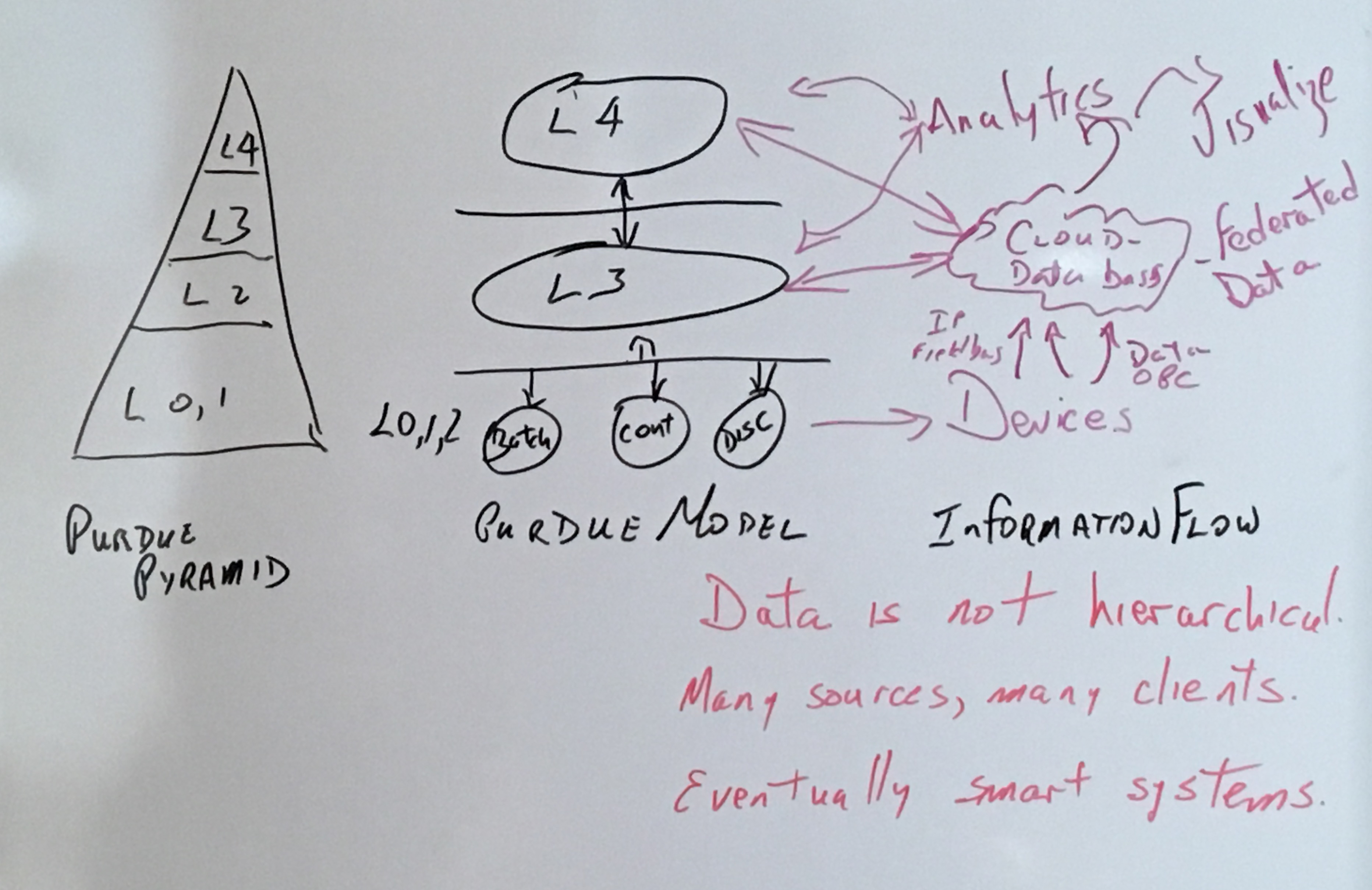

I’ve spent way too much time on the phone and on GoToMeeting over the past several days. So I let the last post on the hierarchy of the Purdue Model sit and ferment. Thanks for the comments.

I’ve spent way too much time on the phone and on GoToMeeting over the past several days. So I let the last post on the hierarchy of the Purdue Model sit and ferment. Thanks for the comments.

Well, I made it sound so simple, didn’t I? I mean, just run a wire around the control system and move data in a non-hierarchical manner to The Cloud. Voila. The Industrial Internet of Things. Devices serving data on the Internet.

Turns out it’s not that simple, is it?

First off, “The Cloud” is actually a data repository (or lots of them) located on a server somewhere and probably within an application of some sort. These applications can be siloed like they mostly are now. Or maybe they share data in a federated manner—the trend of the future.

To accomplish that federation will require standardized ways of describing devices, data, and the metadata. I’ll have more to say about that later relative to some white papers I’m writing for MIMOSA and The OpenO&M Initiative.

Typically data is carried by protocols. OPC (and its latest iteration OPC UA) has been popular in control to HMI applications—and more. Other Internet of Things protocols include XMPP, MQTT, AMQP. Maybe some use JSON. You may have heard of SOAP and RESTful.

Will we live with a multiplicity of protocols? Can we? Will some dominant supplier force a standard?

Check out these recent blogs and articles:

GE Blog – Industrial Internet Protocol Wars

FastCompany, Why the Internet of Things Might Never Speak A Common Language

Inductive Automation Webinar — MQTT the only control protocol you need

OPC – Reshape the Automation Pyramid (is OPC UA all you need?)

Interoperability Among Protocols

What we need is something in the middle that wraps each of the messages in a standard way and delivers to the application or Enterprise Service Bus. Such a technology is described by the OpenO&M Information Service Bus Model that is the core component of the Open Industrial Interoperability Ecosystem (OIIE) that I introduced in the last post. The ISBM is actually not a bus, per se, but a set of APIs based on Web Services. It is also described in ISA 95 Part 6 as Message Service Model (MSM).

The MSM is described in a few points by Dennis Brandl:

- Defines a standard method for interfacing with different Enterprise Service Buses

- Enables sending and receiving messages between applications using a common interface

- Reduces the number of interfaces that must be supported in an integration project

Here is a graphic representation Brandl has developed:

These are simple Web Services designed to remove complexity from the transaction at this stage of communication.

by Gary Mintchell | Mar 15, 2016 | Automation, Internet of Things, Podcast

Manufacturing strategies–my 146th podcast (yes, I don’t get around to them regularly). I look at the discussions around Industrial Internet of Things and Industry 4.0 likening them to strategies.

by Gary Mintchell | Mar 9, 2016 | Automation, Internet of Things, Interoperability, Operations Management, Technology

I’ve been thinking deeply about the industrial internet and the greater industrial ecosystem. A friend passed along an article from ZD Net written by Simon Bisson, “There’s A Huge Void At the Heart of the Internet of Things.”

The deck of the article reads, “Closed systems do not an internet make. It’s time to change that before it’s too late.”

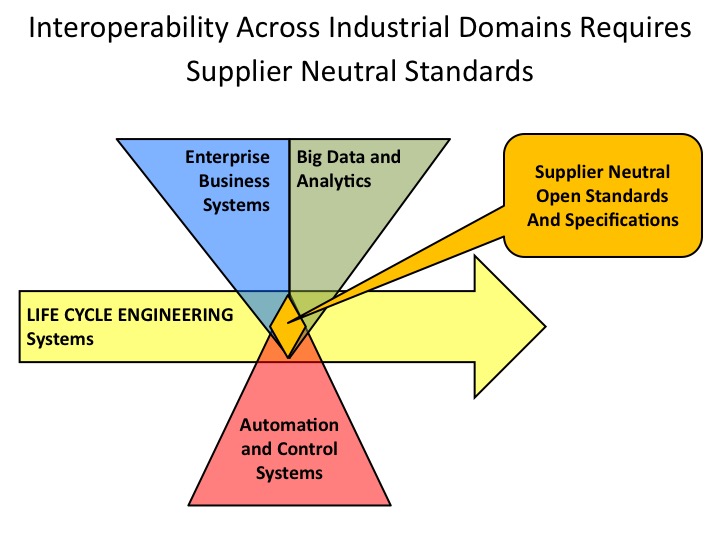

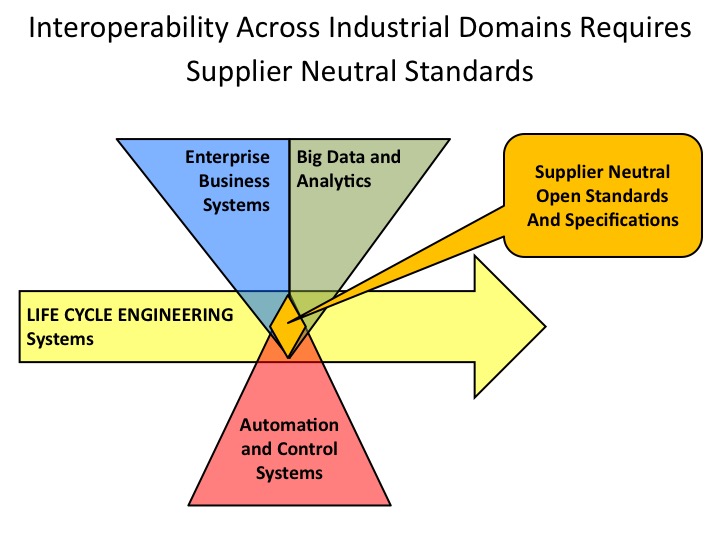

He knew I was working on some white papers for MIMOSA and the OpenO&M Initiative on interoperability of standards in the larger industrial ecosystem. In the case of what I’m writing, there exists a gap in areas covered by Enterprise Business Systems, Big Data and Analytics, Automation and Control Systems, and Life-Cycle Engineering Systems. The gap can be filled with Supplier Neutral Open Standards and Specifications.

Bisson writes, “Sensors are everywhere, but they’re solitary devices, unable to be part of a holistic web of devices that exposes the world around us, giving us the measurements we need to understand and control our environments.”

He notes a few feeble movements toward developing “communication and API standards for these devices, through standards like AllJoyn and Open Connectivity Foundation, the backbone is still missing: a service that will allow us to work with all the devices in our homes.”

Industrial Internet broadly speaking

Typical of a consumer-facing publication, he’s thinking home. I’m thinking industrial in a broad scope.

He continues, “Building that code isn’t hard, either. One of the more interesting IoT development platforms is Node-RED. It’s a semi-visual programming environment that allows you to drag and drop code modules, linking them to a range of inputs and outputs, combining multiple APIs into a node.js-based application that can run on a PC, or in the cloud, or even on devices like the Raspberry Pi.”

Bisson concludes, “The road to an interoperable Internet of Things isn’t hard to find. We just need to remember that our things are now software, and apply the lessons we’ve learnt about building secure and interoperable systems to those software things. And once we’ve got that secure, interoperable set of things, we can start to build the promised world of ubiquitous computing and ambient intelligence.”

I’d take his consumer ideas and apply them to industrial systems. The work I’m doing is to explain an industrial interoperable system-of-systems. I’m about ready to publish the first white paper which is an executive summary. I’m about half done with the longer piece that dives into much greater detail. But he is right. Much has already been invented, developed, and implemented at a certain level. We need to fill the gap now.

by Gary Mintchell | Mar 8, 2016 | Commentary

One set of questions popping up frequently over the past few years among corporate executives of industrial technology supplier companies concerns response to the Industrial Internet of Things regarding industrial merger and acquisition.

Are we in the IIoT market? What acquisitions should we search out to further exploit the IIoT? Should we look at expanding into other aspects of the IIoT market?

Executives analyzing the IIoT system check out networking products plus sensor products plus analysis products. Should I buy into an adjacent area?

One of my favorite new media sites is The Information. It is subscription only. Maybe a model I might morph to someday. Jessica Lessin and her team have assembled a top quality news site covering Silicon Valley entrepreneurs and start ups.

Jessica wrote recently about Yahoo and all the vultures, er companies, circling around to see what sort of deals they may get picking over the various parts of the company that is obviously for sale.

She made this point, “But these two reasons reflect the biggest mistake companies make when it comes to M&A. Executives focus on how a potential deal would help the company get into a new business. But those type of deals, while attractive in theory, often fail miserably. On the other hand, deals that help companies double down on a core business do much better.”

She offers some examples such as AT&T’s purchase of John Malone’s TCI cable company in the late 1990s and News Corp’s $580 million acquisition of MySpace in 2005.

Her advice to those itching to make a deal—just like Pilates, look to your core.

“But the best deals strengthen a company’s core business. The reason is simple: Organizations act in their self-interest; it is how they make money and keep growing. That’s their DNA, more than wishy-washy things like whether employees wear suits or hoodies or work out of a loft or a high-rise.”

Example? “Google pulled that off when it spent $3 billion for DoubleClick in 2007, for example. It was a steep sum but Google already knew search advertising. DoubleClick helped it grow further by selling the similar products to similar customers with display.”

If I’m advising a company again today, I’d pretty much stay with what I thought three years ago—be wary of buying into adjacent or new market areas. To do so requires a clear strategy—and a lot of money.

The only one in the IIoT space of which I’m aware right now is the effort by PTC to enter that space entirely through acquisition. See my post. PTC has acquired at least four companies in the space. A couple it bought for technology. Two it paid huge premiums for. I’m guessing they see such an upside revenue stream that the premium looked small in comparison.

Do you see any other major IIoT plays? I mean other than the German companies focusing on Industrie 4.0 (sort of IIoT plus)—Siemens, Bosch, and others. Rockwell Automation with Connected Enterprise. ABB, GE, and Schneider Electric on IIoT. The big companies are simply focusing efforts they’ve made for years into the new paradigm.

But are there startups to watch? Mid-level acquisitions? Any excitement out there at all? Let me know.

by Gary Mintchell | Mar 3, 2016 | News, Organizations, Standards, Technology

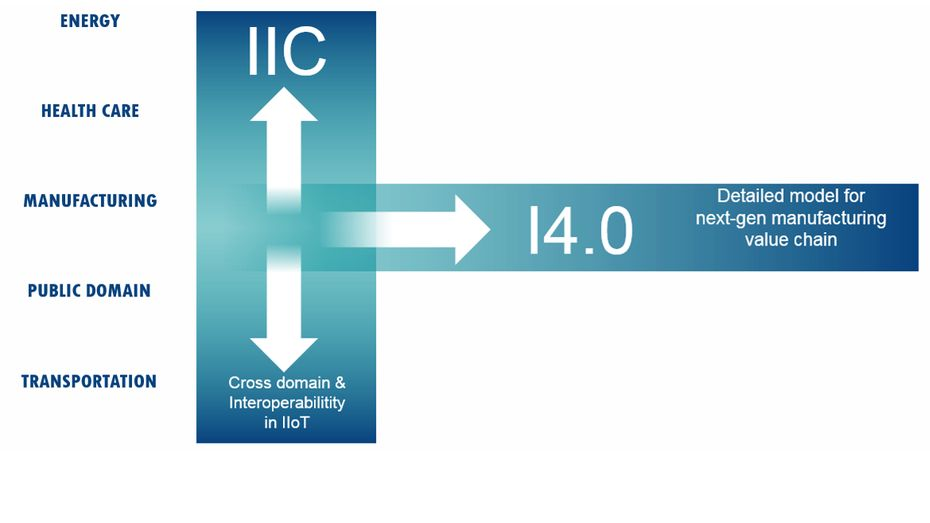

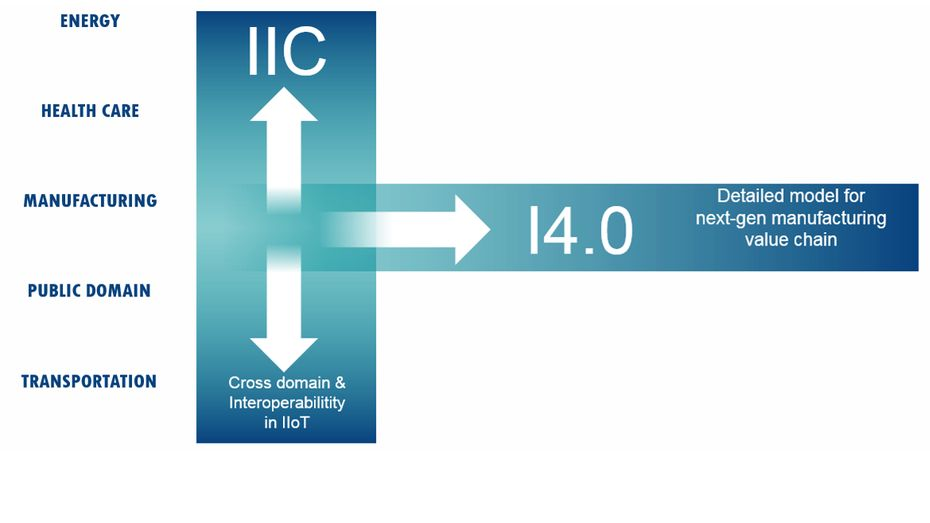

Interoperability among systems spurs economic and technological growth. Two of the leading proponents of new strategies for this next Industrial Revolution that we are beginning recently met.

Interoperability among systems spurs economic and technological growth. Two of the leading proponents of new strategies for this next Industrial Revolution that we are beginning recently met.

Representatives of Plattform Industrie 4.0 and the Industrial Internet Consortium met in Zurich, Switzerland to explore the potential alignment of their two architecture efforts – respectively, the Reference Architecture Model for Industrie 4.0 (RAMI4.0) and the Industrial Internet Reference Architecture (IIRA).

The meeting was a success, with a common recognition of the complementary nature of the two models, an initial draft mapping showing the direct relationships between elements of the models, and a clear roadmap to ensure future interoperability. Additional possible topics included collaboration in the areas of IIC Testbeds and I4.0 Test Facility Infrastructures, as well as standardization, architectures & business outcomes in the Industrial Internet.

The Zurich meeting was originally proposed by Bosch and SAP as members of the steering committees of both organizations. The meeting constituted an informal group which will continue their work on exploring potential alignment between I4.0 and IIC.

The open, informal discovery group included Bosch, Cisco, IIC, Pepperl + Fuchs, SAP, Siemens, Steinbeis Institute and ThingsWise.

Every press release these days, especially when it is an association of many members, includes the requisite quotes. Below are thoughts from some of the leaders.

Industry Reference Architecture Thought Leaders

State Secretary, Matthias Machnig, Ministry for Economic Affairs and Energy: “We welcome the cooperation of both initiatives as an important milestone in the cooperation of companies internationally. The combined strengths of both IIC and Plattform Industrie 4.0 will substantially help to pave the way for a mutually beneficial development of a digitized economy for our international businesses.”

Prof. Dr. Siegfried Russwurm, Technical Director of Plattform Industrie 4.0, CTO and Member of the Managing Board of Siemens AG, said “Collaborating with other initiatives is important, especially for Germany’s export-oriented economy. We are highly interested to cooperate intensively with others in order to pave the way for global standards. Cooperating with IIC – and with other consortia – is an important step in the right direction”

Dr. Richard Mark Soley, Executive Director of the Industrial Internet Consortium, commented, “The effort shows that smart technical people can bridge any gap and find a way to solve problems that might otherwise have created barriers to entry in the adoption of IoT technology for industrial applications. I applaud the participants and thank them for their initial work, and look forward to a successful collaboration moving forward.”

Dr. Werner Struth, member of the Bosch board of management: “This is a huge accomplishment for industry adoption of the Industrial Internet of Things, as it will simplify technology choices immensely and lead to greatly enhanced interoperability.”

Bernd Leukert, Member of the SAP Executive Board emphasizes the importance of alignment between IIC and Plattform Industrie 4.0-initiated testbed initiatives: “This will allow for a much smoother international cooperation between smaller companies and larger enterprise to test out use cases and to initiate standards.”

Greg Petroff, Chief Experience Officer for GE Digital, said: “Breaking down the barriers of technology silos and supporting better integration of these architectures efforts will be key to advancing the Industrial Internet. This collaboration will help build a vibrant, united community around standards that drive integration toward solving the world’s toughest challenges.”

Robert Martin, Senior Principal Engineer in Cyber Security Partnership, The MITRE Corporation and member of the IIC Steering Committee, said “Bringing together the work of the Industrial Internet Consortium and the Plattform Industrie 4.0 Konsortium will dramatically increase the international value of both efforts and help to clarify and resolve the problems and concerns facing the global Industrial IoT marketplace quicker and more effectively than either could do alone.”

“I’m excited to see the two premier Industrial Internet of Things organizations aligning their efforts,” states Stan Schneider, CEO of Real-Time Innovations (RTI) and a member of the IIC Steering Committee. “Industrie 4.0’s strong foundation in industrial manufacturing and process combines well with the IIC’s emphasis on emerging IIoT applications in healthcare, transportation, power, and smart cities. We are working aggressively to align the connectivity infrastructures of the underlying DDS and OPC UA connectivity standards. We look forward to driving the rapid growth of the IIoT across all industries.”

I’ve spent way too much time on the phone and on GoToMeeting over the past several days. So I let the last post on the hierarchy of the Purdue Model sit and ferment. Thanks for the comments.

I’ve spent way too much time on the phone and on GoToMeeting over the past several days. So I let the last post on the hierarchy of the Purdue Model sit and ferment. Thanks for the comments.

Interoperability among systems spurs economic and technological growth. Two of the leading proponents of new strategies for this next Industrial Revolution that we are beginning recently met.

Interoperability among systems spurs economic and technological growth. Two of the leading proponents of new strategies for this next Industrial Revolution that we are beginning recently met.